A nitrogen-oxygen co-doped biomass hard carbon material and its preparation method and application

A biomass material and co-doping technology, applied in the field of electrochemical energy storage, can solve the problems of slow charge transport kinetics and stability, conductivity and potassium storage stability constraints, unfavorable large-scale application, etc., to achieve improved energy storage Potassium cycle performance and rate performance, the effect of improving electrochemical performance, increasing electrochemical active sites and widening the interlayer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of nitrogen and oxygen co-doped biomass hard carbon material, comprising the following steps:

[0030] (1) Clean the mango core shell, place it in a vacuum drying oven for 12 hours at 80° C., and obtain the dried mango core shell;

[0031] (2) Utilize the pulverizer to pulverize the dried mango core-shell, and place it on a vibrating sieve to pass through a 300-mesh screen to obtain uniform mango core-shell powder, which is collected for use;

[0032] (3) Weigh 50g of powder and place it in a tube furnace, raise the temperature to 900°C at a rate of 3°C / min under an inert atmosphere and keep it warm for carbonization for 2 hours, and take it out when the temperature drops to 25°C to obtain nitrogen and oxygen co-doping Biomass hard carbon materials.

[0033] The nitrogen-oxygen co-doped biomass hard carbon material obtained in Example 1 was tested by X-ray photoelectron spectroscopy, the content of carbon element was 93.31wt%, the content of nitrog...

Embodiment 2

[0036] A preparation method of nitrogen and oxygen co-doped biomass hard carbon material, comprising the following steps:

[0037] (1) cleaning the mango core shell, placing it in a vacuum drying oven for 24 hours at 80° C. to obtain the dried mango core shell;

[0038] (2) Utilize the pulverizer to pulverize the dried mango core-shell, and place it on a vibrating sieve to pass through a 500-mesh screen to obtain uniform mango core-shell powder, which is collected for use;

[0039] (3) Weigh 50g of powder and place it in a tube furnace, raise the temperature to 1100°C at a heating rate of 5°C / min under an inert atmosphere and keep it warm for carbonization for 2 hours, take it out when the temperature drops to room temperature, and obtain the nitrogen-oxygen co-doped product. Material hard carbon material.

[0040] The nitrogen and oxygen co-doped biomass hard carbon material obtained in Example 2 was tested by X-ray photoelectron spectroscopy, the content of carbon element w...

Embodiment 3

[0043] (1) Clean the mango core shell, place it in a vacuum drying oven and dry it at 80°C for 10 hours to obtain the dried mango core shell;

[0044] (2) Utilize the pulverizer to pulverize the dried mango core-shell, and place it on a vibrating sieve to pass through a 1000-mesh screen to obtain uniform mango core-shell powder, which is collected for use;

[0045] (3) Weigh 50g of the powder and place it in a tube furnace, raise the temperature to 1300°C at a rate of 3°C / min under an inert atmosphere, keep it warm for carbonization for 2.5h, and take it out when the temperature drops to room temperature to obtain the final product.

[0046] The nitrogen-oxygen co-doped biomass hard carbon material obtained in Example 3 was tested by X-ray photoelectron spectroscopy, and the content of carbon element was 93.64wt%, the content of nitrogen element was 0.98wt%, and the content of oxygen element was 4.90wt% %, the content of calcium element is 0.48wt%.

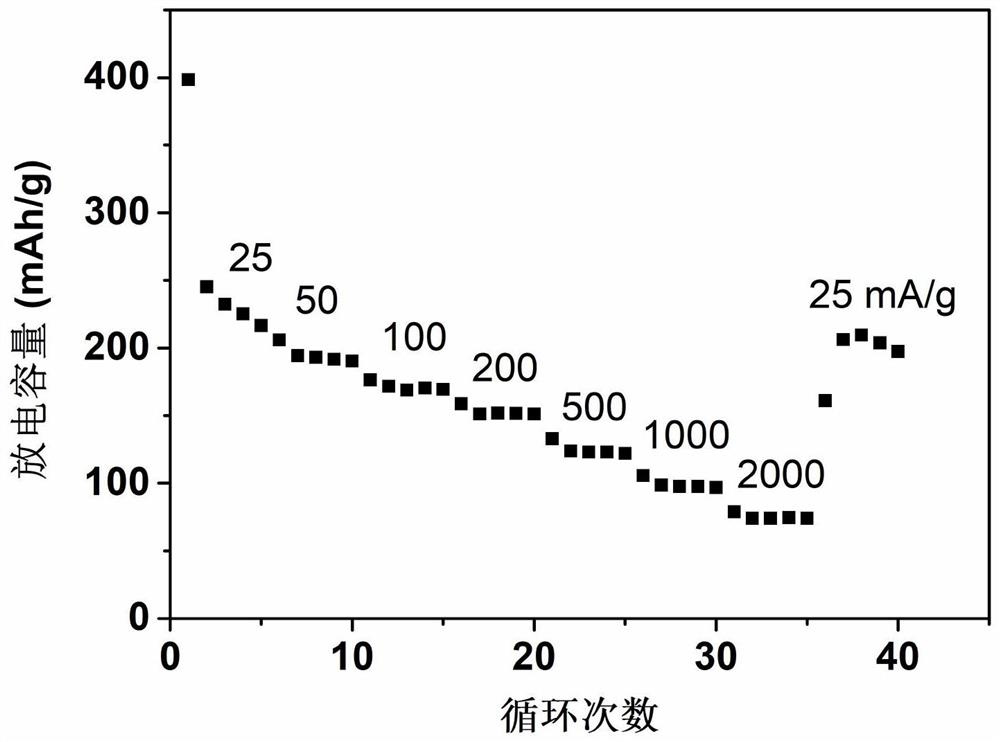

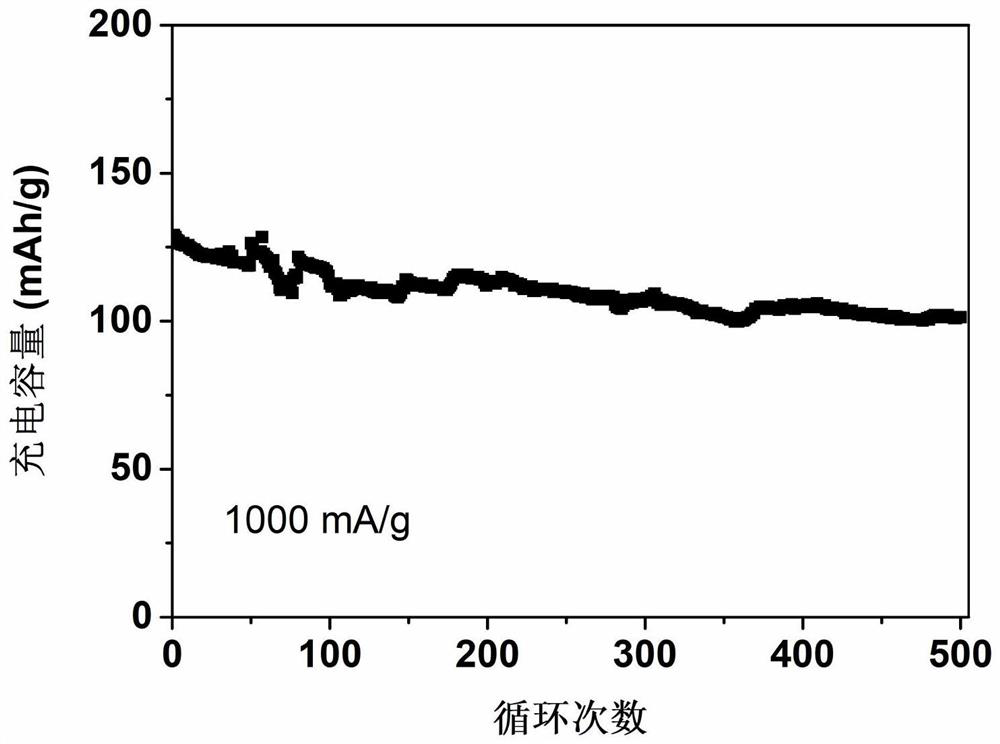

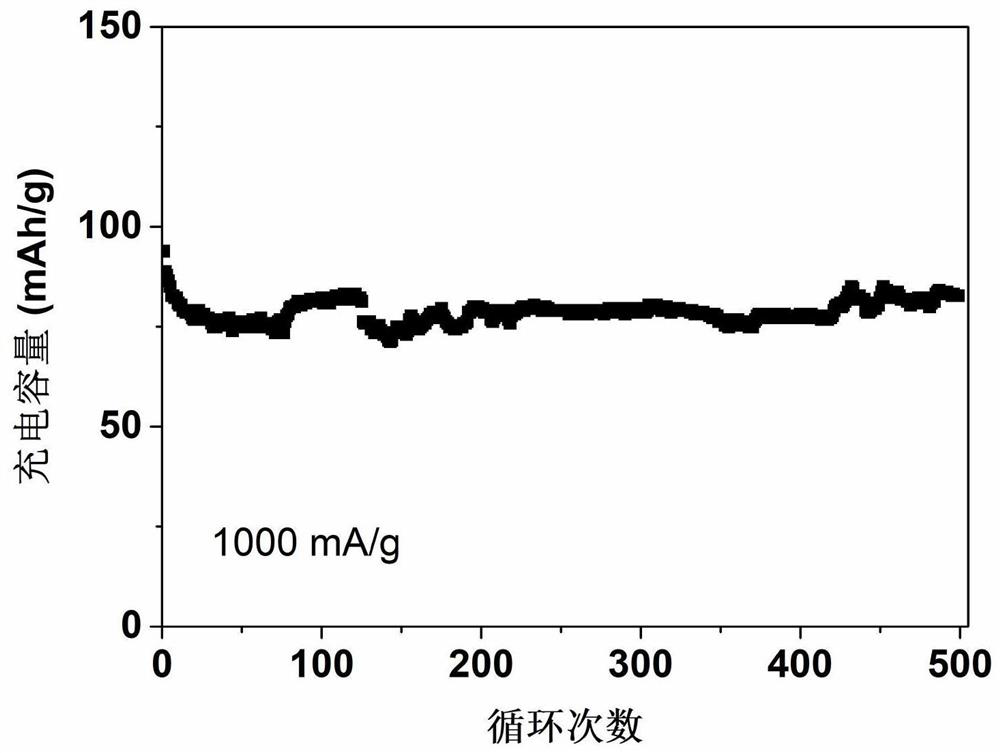

[0047] The nitrogen and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com