A preparation method of nanofiber gel composite matrix for constructing skin tissue

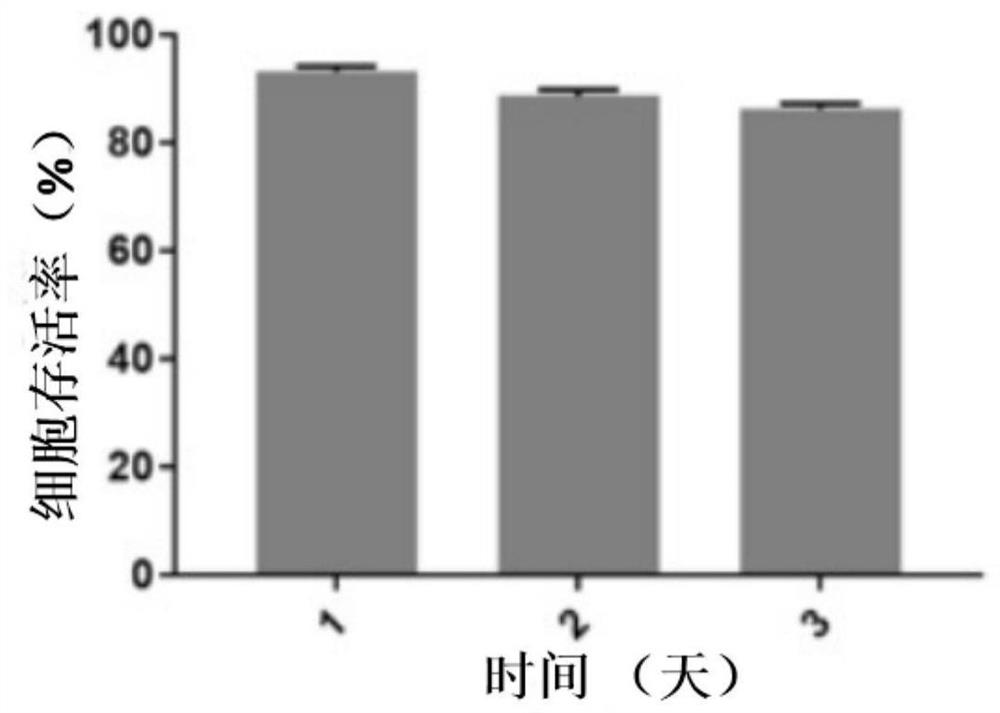

A nanofiber, composite matrix technology, applied in cellulose/protein conjugated rayon, pharmaceutical formulations, non-woven fabrics, etc., can solve the problem of difficulty in preparing large-area nanofiber scaffold materials, and achieve the prevention of wound infection, Excellent biocompatibility, the effect of promoting cell recruitment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

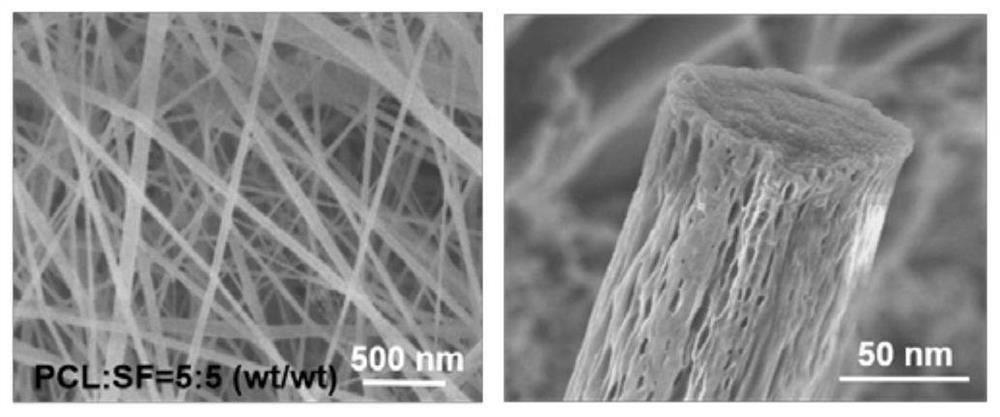

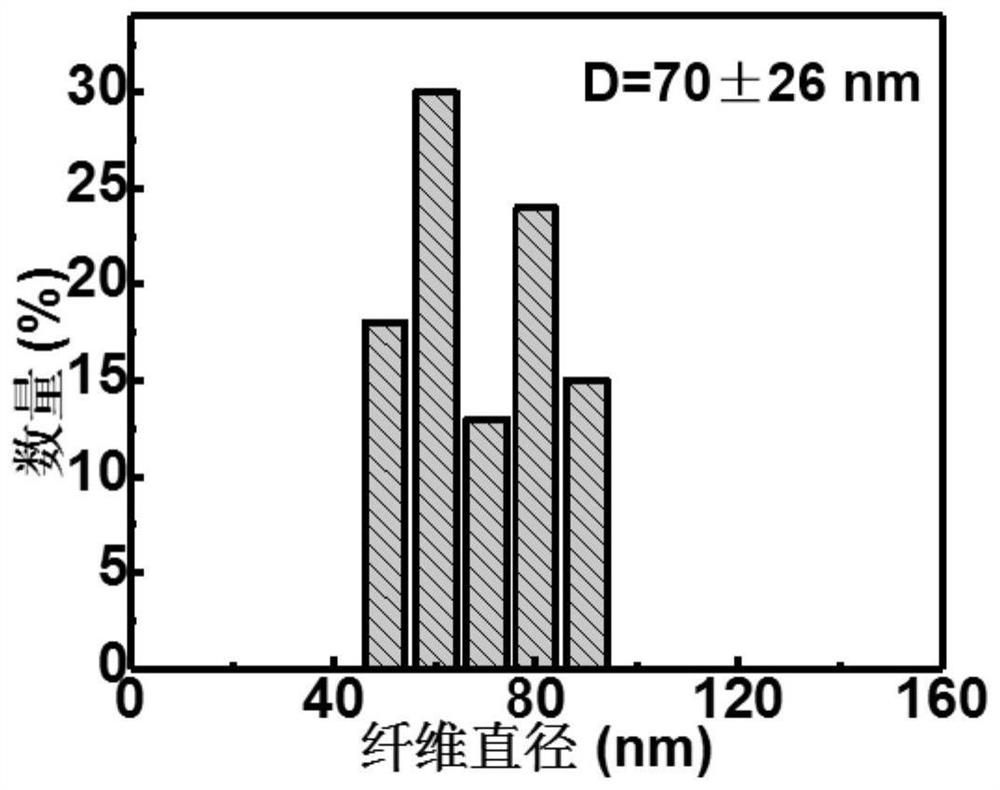

Embodiment 1

[0034] Inject 15 g of the main glue solution in the pig-source fibrin adhesive into 0.3 g of the main glue freeze-dried powder to obtain a 1.96 wt % fibrin solution. Then 0.5g PCL (weight average molecular weight 80000), 2.0g dry SF were dissolved in the solution containing 15g formic acid (the mass concentration of the formic acid solution was 85%), and it was fully stirred at room temperature for 6h to obtain a mass fraction of 14.2 wt% PCL / SF spinning solution (the mass ratio of PCL to SF is 0.25). The obtained PCL / SF spinning solution is used as the internal phase, the fibrin solution is used as the external phase, and the two solutions are used as the reservoir of the precursor, and loaded into a syringe. The two injectors were respectively connected to the two inlets of the T-shaped microfluidic chip as reactors for preparing fibrin-coated PCL / SF nanofibers. A stainless steel passivated needle (24G) was used to feed the prepared spinning solution at a fixed feed rate (0...

Embodiment 2

[0036]Inject 15 g of the main glue solution in the pig-source fibrin adhesive into 0.5 g of the main glue freeze-dried powder to obtain a 3.33 wt % fibrin solution. Then 0.9g PCL (weight-average molecular weight 80000), 2.1g dry SF are dissolved in containing 15g formic acid, make it fully stir 6h at room temperature and make mass fraction be the PCL / SF spinning solution of 16.7%wt%. 0.428, w / w). The obtained PCL / SF spinning solution is used as the internal phase, the fibrin solution is used as the external phase, and the two solutions are used as the reservoir of the precursor, and loaded into a syringe. The two injectors were respectively connected to the two inlets of the T-shaped microfluidic chip as reactors for preparing fibrin-coated PCL / SF nanofibers. A stainless steel passivated needle (24G) was used to feed the prepared spinning solution at a fixed feed rate (1.5 mL / h and 5 mL / h for the inner and outer parts, respectively). During the MBS process, the air pressure ...

Embodiment 3

[0038] Inject 15 g of the main glue solution in the pig-source fibrin adhesive into 0.75 g of the main glue freeze-dried powder to obtain a 4.76 wt % fibrin solution. Then 3.5g of PCL (weight average molecular weight 80000), 1.5g of dry SF were dissolved in a 25mL beaker containing 15g of formic acid, and it was fully stirred at room temperature for 6h to prepare a mass fraction of 25wt% PCL / SF spinning solution (2.33, w / w). The obtained PCL / SF spinning solution is used as the internal phase, the fibrin solution is used as the external phase, and the two solutions are used as the reservoir of the precursor, and loaded into a syringe. The two injectors were respectively connected to the two inlets of the T-shaped microfluidic chip as reactors for preparing fibrin-coated PCL / SF nanofibers. A stainless steel passivated needle (24G) was used to feed the prepared spinning solution at a fixed feed rate (5 mL / h and 0.1 mL / h for the inner and outer parts, respectively). During the M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com