Binary metal oxide composite carbon nitride catalyst, preparation method and applications thereof

A composite carbon nitride and binary metal technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of nitrobenzene and nitrobenzene homologs It can solve the problems of low waste treatment effect and achieve good industrial application prospects, high degradation efficiency and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

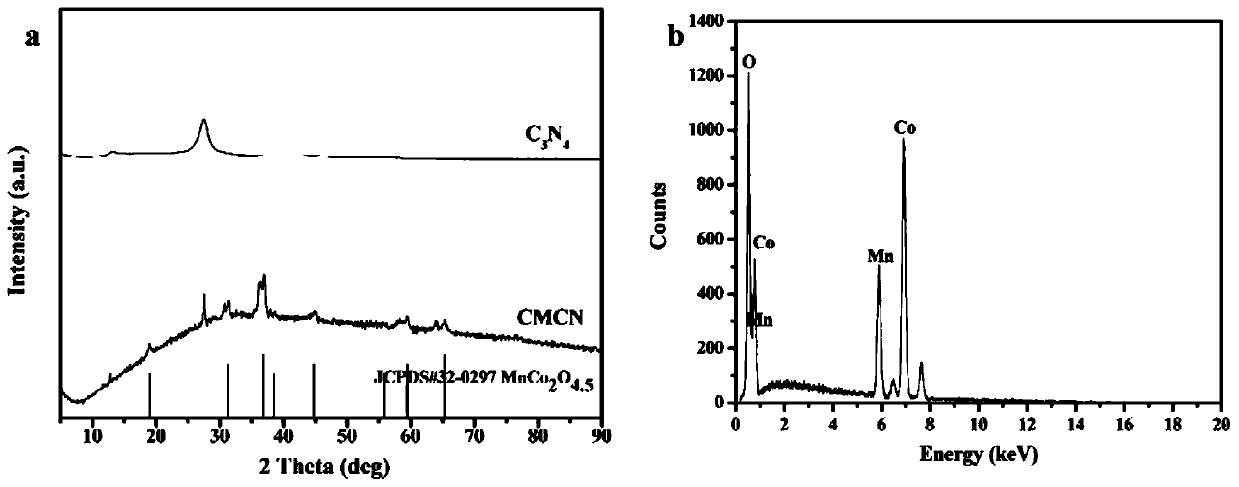

[0043] Embodiment 1 of the present invention: a binary metal oxide composite carbon nitride catalyst, the chemical composition of the catalyst is MnCo 2 o 4 / C 3 N 4 , its preparation steps are as follows:

[0044] (1) At room temperature, weigh 4.35g Co(NO 3 ) 2 ·6H 2 O, 1.23g Mn(CH 3 COO) 2 4H 2 O and 5g DCD were dispersed in 50mL deionized water by ultrasonic, and dissolved completely under magnetic stirring.

[0045] (2) The reaction solution obtained in step (1) was heated to 80° C. under magnetic stirring and kept for 2 hours until the deionized water in the solution system evaporated completely and crystals were precipitated.

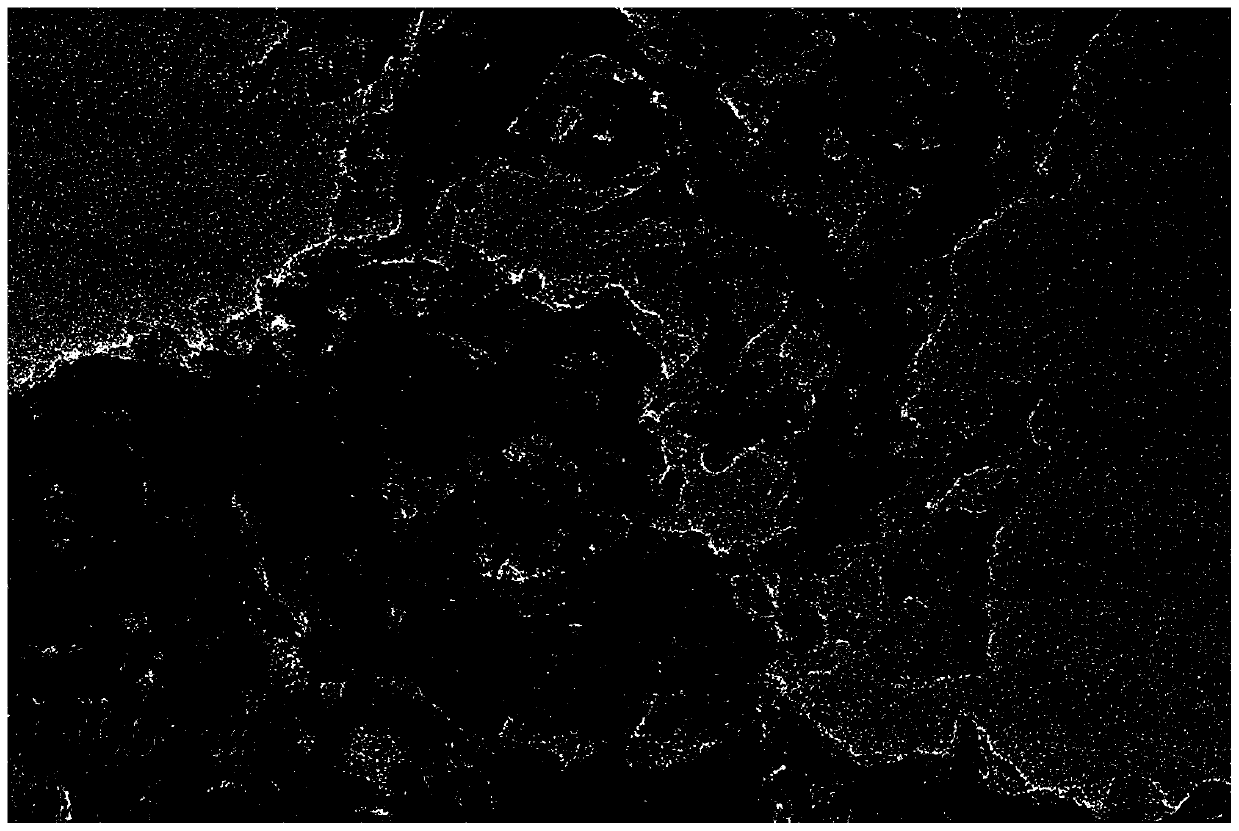

[0046] (3) Grind the obtained crystalline substance into powder, dry it in an oven at 120°C for 5h, transfer it to a muffle furnace, and roast it at 575°C for 4h (the muffle furnace heats up to 575°C at a rate of 5°C / min) , thus making MnCo 2 o 4 / C 3 N 4 catalyst. Get the catalyst that above-mentioned embodiment makes and carry ou...

Embodiment 2

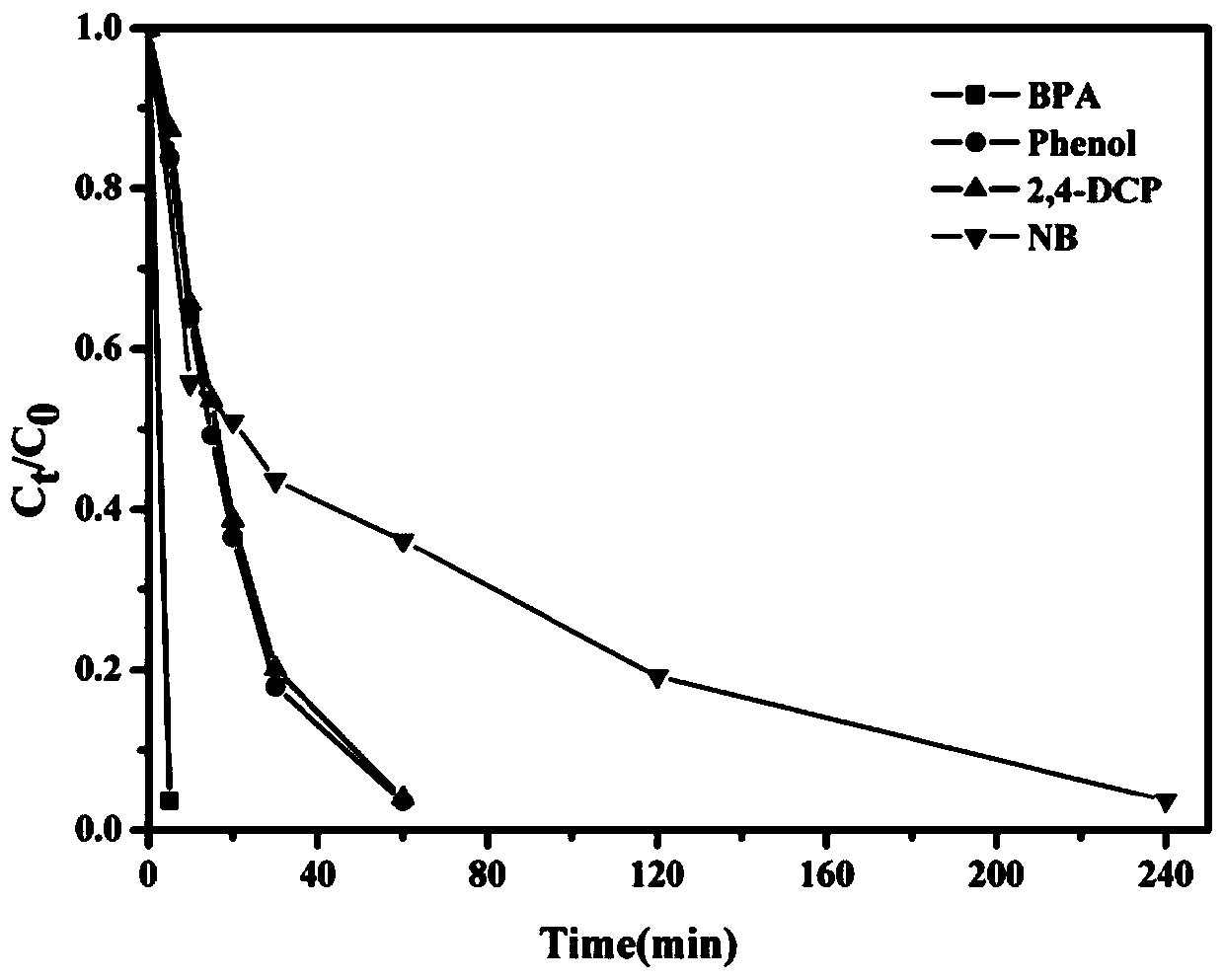

[0047] Embodiment 2 of the present invention is: a treatment method for organic waste water, the MnCo prepared in Embodiment 1 2 o 4 / C 3 N 4 Catalyst Activation Peroxymonosulfate (Potassium peroxymonosulfate, PMS) was used for the degradation of organic pollutants in wastewater to evaluate its catalytic activity.

[0048] Accurately take the prepared catalyst 10mg in 50mL concentration of 50mg / L of different waste liquids (bisphenol A (Bisphenol A, BPA), phenol (Phenol), 2,4-dichlorophenol (2,4-Dichlorophenol, 2 , 4-DCP) and nitrobenzene (Nitrobenzene, NB)), under the condition of continuous stirring, 20mg of persulfate was added for degradation reaction. For different pH conditions (pH = 3 ~ 10), the wastewater containing nitrobenzene is adjusted in advance with acid or alkali to simulate different pH environments, and then degraded according to the above process. All the above experiments are carried out at room temperature .

[0049] Take solutions with different reac...

Embodiment 3

[0050] Embodiment three of the present invention is: a treatment method of organic wastewater, the prepared MnCo 2 o 4 / C 3 N 4 Catalyst activation of peroxymonosulfate for the degradation of organic pollutants in petrochemical wastewater to evaluate its practical applicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com