Sulfhydrylated graphene aerogel as well as preparation method and application thereof

A thiolated graphene and aerogel technology, applied in the field of materials, can solve the problems of high preparation cost and insufficient adsorption capacity, and achieve the effects of low water solubility, safe and controllable experimental conditions, and excellent adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

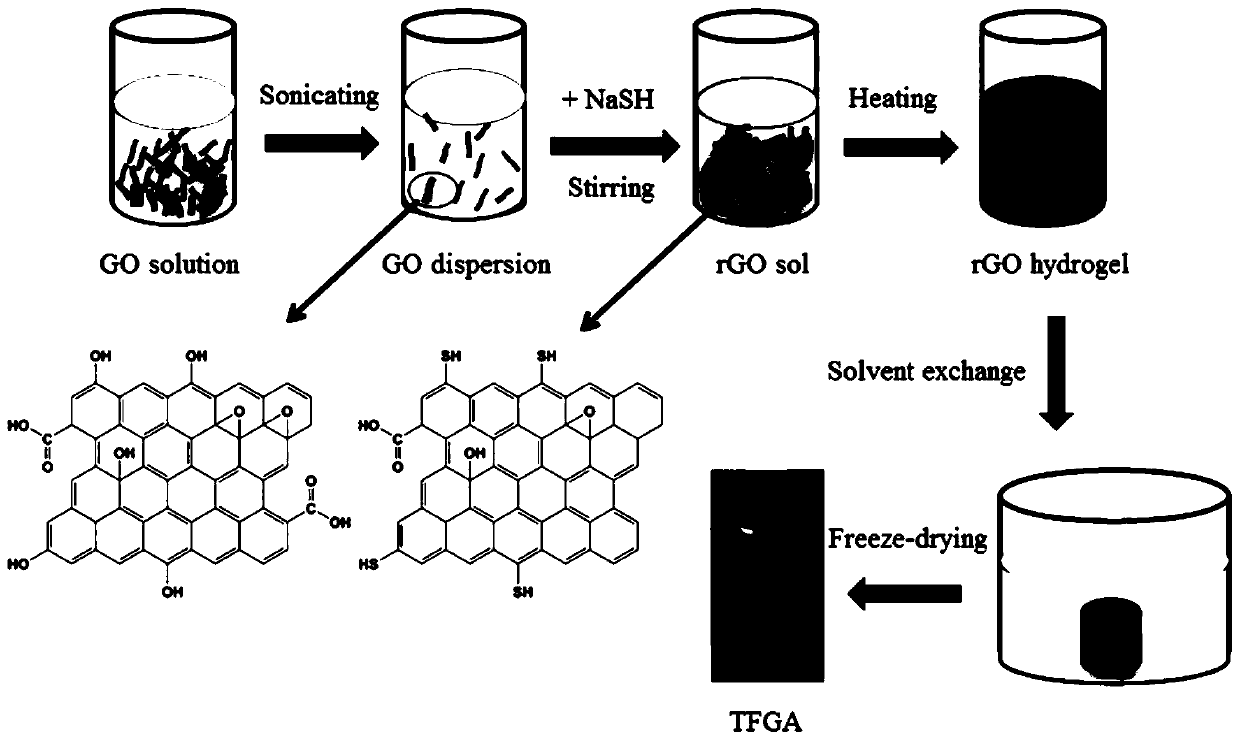

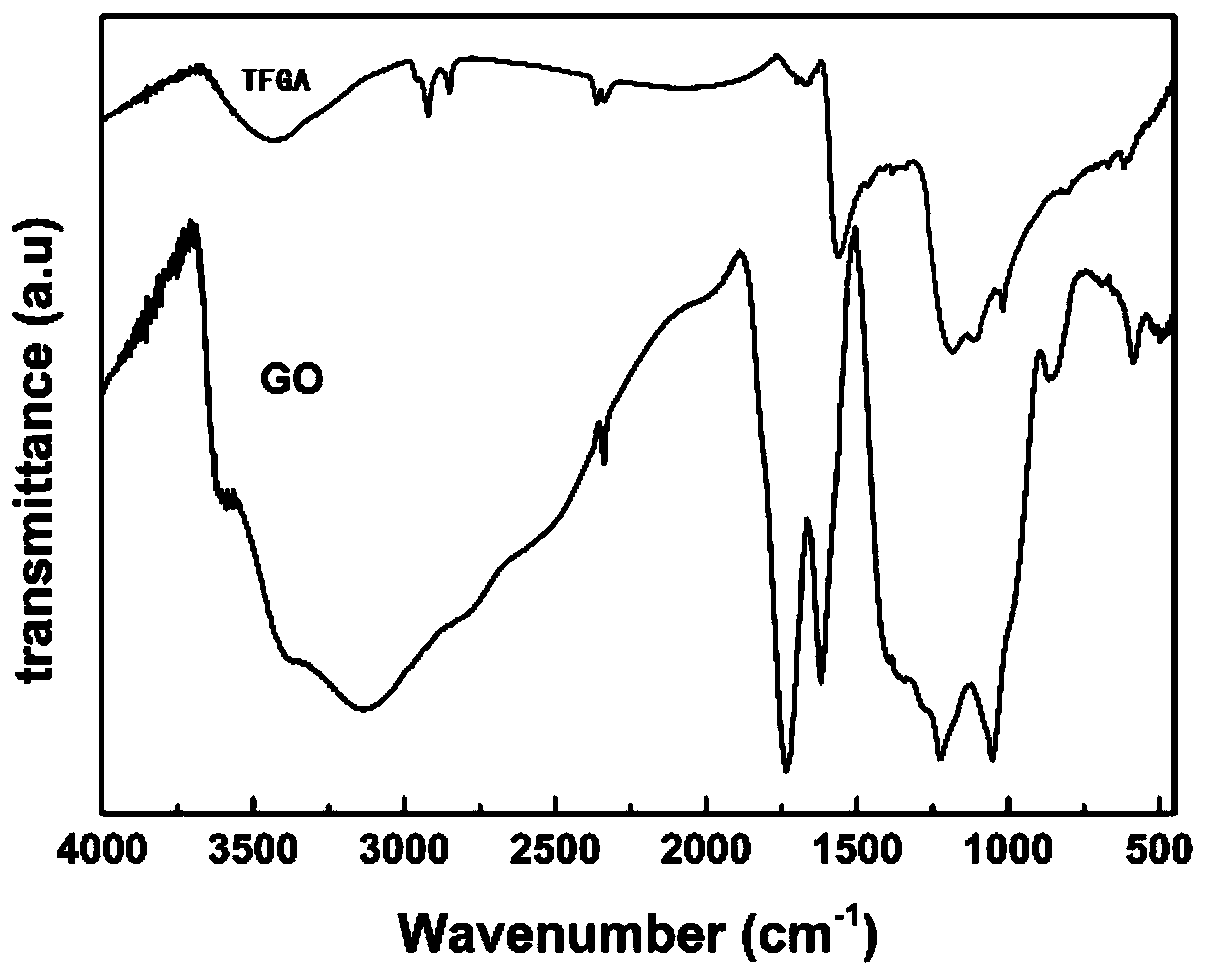

[0038] The preparation of embodiment 1 mercaptolated graphene airgel (TFGA-1)

[0039] Add 0.6g of graphite oxide powder (GO, purchased from Changzhou Sixth Element Materials Technology Co., Ltd.) into deionized water at room temperature, and stir evenly with magnetic force to obtain a graphene oxide colloidal suspension; the graphene oxide colloidal suspension was ultrasonically After 1 hour, a uniform and stable 6 mg / mL graphene oxide dispersion was formed. Dissolve 0.3 g of sodium hydrosulfide in 2 mL of deionized water to obtain an aqueous solution of sodium hydrosulfide, slowly add the aqueous solution of sodium hydrosulfide dropwise into a sample bottle containing a graphene oxide dispersion while stirring to obtain a mixture, and then place the The sample bottle of the mixture was transferred to a vacuum oven at 65° C., and reacted for 7 hours to obtain a mercaptolated graphene hydrogel.

[0040] The mercaptolated graphene hydrogel obtained is transferred to a large be...

Embodiment 2

[0041] The preparation of embodiment 2 mercaptographene airgel (TFGA-2)

[0042] Add 0.4g of graphite oxide powder into deionized water at room temperature, and stir evenly with a magnetic force to obtain a graphene oxide colloidal suspension; ultrasonicate the graphene oxide colloidal suspension for 1 hour to form a uniform and stable 4mg / mL graphene oxide dispersion liquid. Dissolve 0.2 g of sodium hydrosulfide in 2 mL of deionized water to obtain an aqueous solution of sodium hydrosulfide, slowly add the aqueous solution of sodium hydrosulfide dropwise into a sample bottle containing a graphene oxide dispersion while stirring to obtain a mixture, and then place the The sample vial of the mixture was transferred to a vacuum oven at 55° C., and reacted for 11 hours to obtain a mercaptolated graphene hydrogel.

[0043]The mercaptolated graphene hydrogel obtained is transferred to a large beaker, and then moved into an aqueous ethanol solution (wherein the volume of ethanol ac...

Embodiment 3

[0044] The preparation of embodiment 3 mercaptolated graphene airgel (TFGA-3)

[0045] Add 0.5g of graphite oxide powder into deionized water at room temperature, and stir evenly with a magnetic force to obtain a graphene oxide colloidal suspension; ultrasonicate the graphene oxide colloidal suspension for 1 hour to form a uniform and stable 5 mg / mL graphene oxide dispersion liquid. Dissolve 0.25 g of sodium hydrosulfide in 2 mL of deionized water to obtain an aqueous solution of sodium hydrosulfide, slowly add the aqueous solution of sodium hydrosulfide dropwise into a sample bottle containing a graphene oxide dispersion while stirring to obtain a mixture, and then place the The sample vial of the mixture was transferred to a vacuum oven at 75° C., and reacted for 7 hours to obtain a mercaptolated graphene hydrogel.

[0046] The obtained mercaptolated graphene hydrogel is transferred to a large beaker, and then it is added to an aqueous ethanol solution (wherein the volume o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com