Preparation method of isopropyl thioxanthone

A technology of isopropylthioxanthone and propylphenyl sulfide, which is applied in the field of preparation of isopropylthioxanthone, can solve the problems of high environmental protection treatment cost, reduced product yield, low product purity and the like, and achieves saving Economical cost, reduction of impurities and carbides, high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The invention provides a preparation method of isopropylthioxanthone (ITX), comprising the following steps:

[0048] ① The 2-(4-cumyl thio) benzoic acid and polyphosphoric acid are mixed and reacted according to the weight ratio of 1:1.25 to obtain a reaction solution;

[0049] 2. Add the reaction solution obtained in step 1 into water, stir, heat, add liquid caustic soda after removing the lower layer of water, adjust the pH value of the reaction solution, and separate the lower layer of oil layer;

[0050] 3. dehydration and rectification are carried out to the lower oil layer, and a middle distillate is divided, and the divided middle distillate is heated and cooled in a vacuum to obtain a crude oil phase substance;

[0051] ④ Purify the oil phase obtained in step ③ and methanol under certain conditions to obtain crystals;

[0052] ⑤ Dry the crystal obtained in step ④ to obtain isopropylthioxanthone.

[0053] Preferably in the above technical scheme, in the reactio...

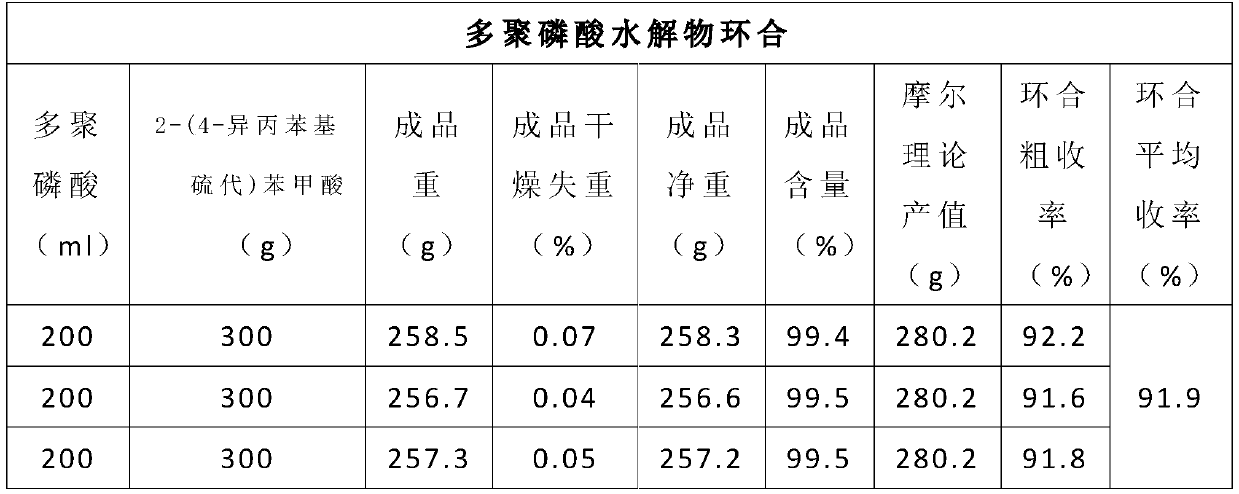

Embodiment 2

[0067] In one embodiment, the preparation method of isopropylthioxanthone (ITX) of the present invention comprises the following steps:

[0068] 1. 2-(4-isopropylphenylthio)benzoic acid and polyphosphoric acid are mixed and reacted in a ratio of 1:1.35 by weight to obtain a reaction solution;

[0069] 2. Add the reaction solution obtained in step 1. into water, stir, heat, add liquid caustic soda after removing the lower layer of water, adjust the pH value of the reaction solution, and separate and take the lower layer of oil layer;

[0070] ③ Dehydrating and rectifying the lower oil layer, fractionating the middle distillate, heating and vacuum cooling the fractionated middle distillate to obtain the crude oil phase;

[0071] ④ refining the oil phase obtained in step ③ with methanol under certain conditions to obtain crystals;

[0072] ⑤ drying the crystals obtained in step ④ to obtain isopropylthioxanthone.

[0073] Preferably in the above technical scheme, in the reaction...

Embodiment 3

[0087] In one embodiment, the preparation method of isopropylthioxanthone (ITX) of the present invention comprises the following steps:

[0088] 1. 2-(4-isopropylphenylthio)benzoic acid and polyphosphoric acid are mixed and reacted in a ratio of 1:1.45 by weight to obtain a reaction solution;

[0089] 2. Add the reaction solution obtained in step 1. into water, stir, heat, add liquid caustic soda after removing the lower layer of water, adjust the pH value of the reaction solution, and separate and take the lower layer of oil layer;

[0090] ③ Dehydrating and rectifying the lower oil layer, fractionating the middle distillate, heating and vacuum cooling the fractionated middle distillate to obtain the crude oil phase;

[0091] ④ refining the oil phase obtained in step ③ with methanol under certain conditions to obtain crystals;

[0092] ⑤ drying the crystals obtained in step ④ to obtain isopropylthioxanthone.

[0093] Preferably in the above technical scheme, in the reaction...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap