Heat-insulation ablation-resistant maintainable repairing agent and coating dual-purpose slurry, preparation method and application

A kind of anti-ablation and repairing agent technology, applied in the direction of coating, etc., can solve the problems of increasing cost, poor compatibility between coating and substrate, high coating density, etc., to improve heat resistance temperature and time, and avoid solvent volatilization loss , good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A dual-purpose slurry for a heat-insulating, ablation-resistant, maintainable repair agent and a coating, the slurry is composed of a main component and an additional component, based on the total mass of the main component being 100%. The fractions are as follows: silicone resin 40%, high temperature resistant filler 60%; the composition and mass fraction of the added components are as follows: the mass fraction of the solvent is 60% of the mass of the main component; the mass fraction of the additive is the mass of the main component 1.5%.

[0042] The silicone resin is methylphenyl silicone resin.

[0043] The high temperature resistant filler is composed of boron carbide, titanium dioxide, kaolin, chopped mullite fiber, hollow glass microspheres and silica hollow microspheres in a mass ratio of 2:2:3:1:4:3.

[0044] The solvent is absolute ethanol.

[0045] The auxiliary agent is a mixed solution of silane coupling agents KH550 and KH-560, and the mass ratio of KH...

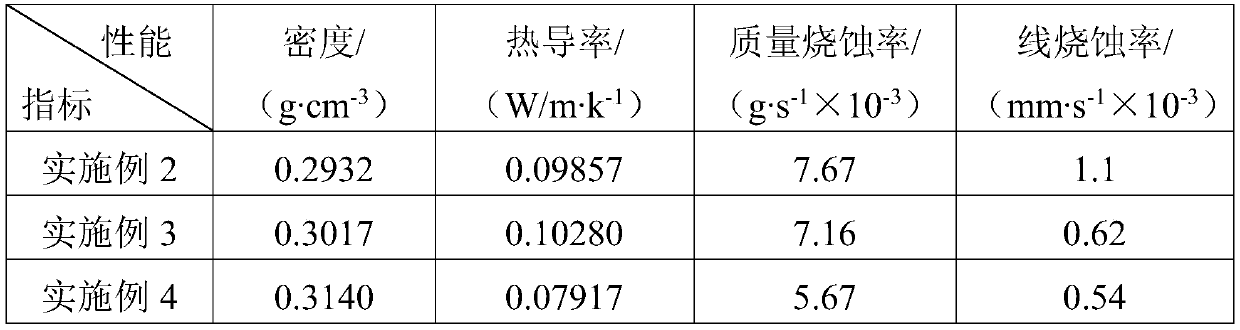

Embodiment 2

[0051] A dual-purpose slurry for a heat-insulating, ablation-resistant, maintainable repair agent and a coating, the slurry is composed of a main component and an additional component, based on the total mass of the main component being 100%. The fractions are as follows: silicone resin 40%, high temperature resistant filler 60%; the composition and mass fraction of the added components are as follows: the mass fraction of the solvent is 70% of the mass of the main component; the mass fraction of the additive is the mass of the main component 2.5%.

[0052] The silicone resin is a mixture of methyl silicone resin and phenyl silicone resin, and the mass ratio of methyl silicone resin and phenyl silicone resin is 2:1.

[0053]The high temperature resistant filler is composed of boron carbide, silicon powder, kaolin, boron trioxide and mica powder in a mass ratio of 2:1:3:1:3.

[0054] The solvent is a mixed solution of xylene and absolute ethanol, and the mass ratio of xylene t...

Embodiment 3

[0061] A dual-purpose slurry for a heat-insulating, ablation-resistant, maintainable repair agent and a coating, the slurry is composed of a main component and an additional component, based on the total mass of the main component being 100%. The fractions are as follows: silicone resin 50%, high temperature resistant filler 50%; the composition and mass fraction of the added components are as follows: the mass fraction of the solvent is 65% of the mass of the main component; the mass fraction of the additive is the mass of the main component 2%.

[0062] The silicone resin is a mixture of methyl silicone resin and phenyl silicone resin, and the mass ratio of methyl silicone resin and phenyl silicone resin is 1:1.

[0063] The high temperature resistant filler is composed of boron carbide, boron nitride, silicon dioxide, aluminum oxide and mica powder in a mass ratio of 1:1:3:2:3.

[0064] The solvent is a mixed solution of toluene and xylene, and the mass ratio of toluene to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com