Room-temperature fast vulcanization condensation type heat-conducting pouring sealant and preparation method thereof

A potting glue and condensation-type technology, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of improved flame retardancy, thermal conductivity, and overall mechanical properties, and achieves rapid curing and production. The effect of low cost and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

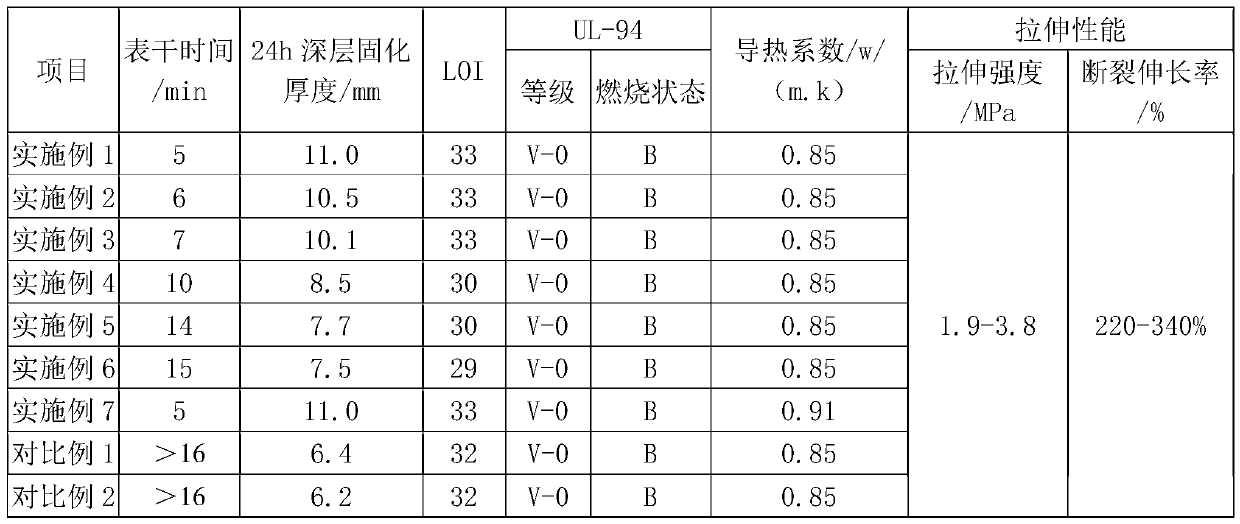

Examples

Embodiment 1

[0045] a. Clean and preheat the vacuum mixing equipment to 60°C;

[0046] b. Add 35 parts of hydroxyl-terminated polysiloxane with a viscosity of 1500 mps.s and 15 parts of hydroxyl-terminated polysiloxane with a viscosity of 20,000 mps.s, with a solid content of 50% (150°C*2H), MQ 5 parts of SH-MQ silicone resin with a ratio of 0.5-0.8:1 and a specific surface area of 300m 2 5 parts per g of hexamethyldisilazane modified fumed silica, 30 parts of the compound of guanidine sulfamate and guanidine polyphosphate, the weight ratio is 4:1, 12.5 parts of aluminum nitride, ultraviolet light 1 part of stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 2 parts of heat stabilizer nanometer ferric oxide with a particle size of 40nm, structure control agent methylbenzene 2 parts of diethoxysilane and 2 parts of defoamer XP-008, and stirred, and heated to 120 ° C, vacuumed to 0.6mpa;

[0047] c. Mix for 2 hours, stop stirring and heating, and store in airtight;

[0048] d. A...

Embodiment 2

[0052] The rest are the same as in Example 1, except that the weight ratio of guanidine sulfamate and guanidine polyphosphate is 2:1.

Embodiment 3

[0054] The rest are the same as in Example 1, except that the weight ratio of guanidine sulfamate and guanidine polyphosphate is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com