Special oil for 75W-90 viscosity grade vehicle gear, and preparation method thereof

A special oil and grade technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of oil product applicability decline, viscosity decline, etc., and achieve the effects of improved oxidation resistance, reduced sludge tendency, and beneficial detergency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

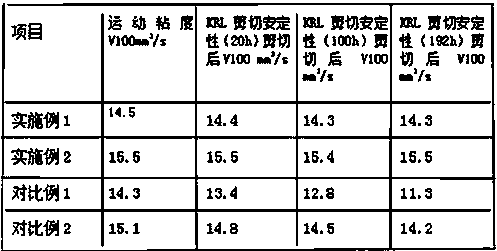

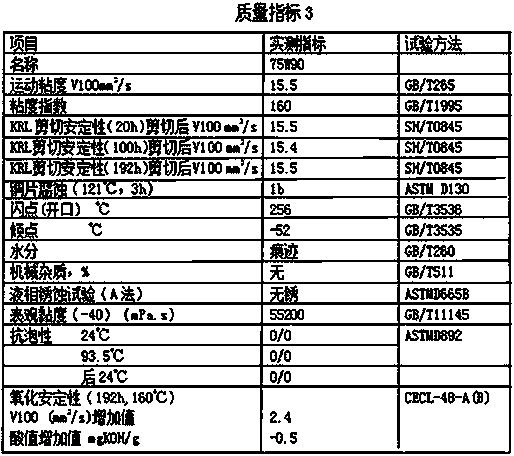

Embodiment 1

[0018] Embodiment 1: a kind of 75W90 vehicle gear special oil, prepare polyalphaolefin PAO6: 447kg, alkyl naphthalene AN5: 216kg, metallocene polyalphaolefin SpectraSyn Elite 150: 337kg, antirust agent: amide antirust agent 2.5kg, Antioxidant: octyl / butyl liquid diphenylamine 5kg, anticorrosion agent: molybdenum dialkyldithiosulfate 20kg, antiwear agent: tricresyl phosphate 10kg, extreme pressure agent: isobutylene vulcanization 30kg, friction modifier: benzene tris Azole fatty amine salt 1kg, dispersant: medium alkali value synthetic calcium sulfonate 2kg, defoamer: composite antifoam agent 0.04kg

[0019] Production method: (1), put polyalphaolefin, alkylnaphthalene, and metallocene polyalphaolefin into the reaction kettle, heat up to 60-70°C, and stir for 10-30 minutes;

[0020] (2), antirust agent: amide antirust agent, antioxidant: octyl / butyl liquid diphenylamine, anticorrosion agent: molybdenum dialkyl dithiosulfate, antiwear agent: tricresyl phosphate, extreme pressure...

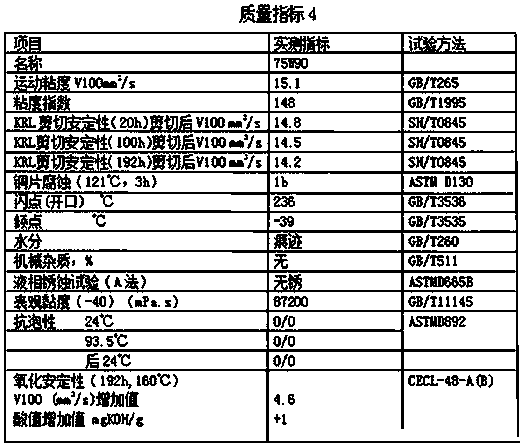

Embodiment 2

[0025] Embodiment 2: a kind of 75W90 special oil for vehicle gears, prepare polyalphaolefin PAO6:298kg, alkylnaphthalene AN5:216kg, metallocene polyalphaolefin SpectraSyn Elite 65:486kg, antirust agent: amide antirust agent 2.5kg, Antioxidant: octyl / butyl liquid diphenylamine 5kg, anticorrosion agent: molybdenum dialkyl dithiosulfate 20kg, antiwear agent: tricresyl phosphate 10kg, extreme pressure agent: sulfurized isobutylene 30kg, friction modifier: benzene Triazole fatty amine salt 1kg, dispersant: medium alkali value synthetic calcium sulfonate 2kg, defoamer: composite antifoam agent 0.04kg

[0026] Production method: (1), put polyalphaolefin, alkylnaphthalene, and metallocene polyalphaolefin into the reaction kettle, heat up to 60-70°C, and stir for 10-30 minutes;

[0027] (2) Antirust agent: amide antirust agent, antioxidant: octyl / butyl liquid diphenylamine, anticorrosion agent: molybdenum dialkyl dithiosulfate, antiwear agent: tricresyl phosphate, extreme pressure agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com