Method for modifying polytetrafluoroethylene-aramid blended fabric jointly by dopamine-polyethyleneimine-nanoparticles

A technology of polyethyleneimine and polytetrafluoroethylene, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve the problems of expensive experimental equipment, high reaction temperature, complex reaction conditions, etc., and achieve simple operation and excellent reaction conditions Gentle, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

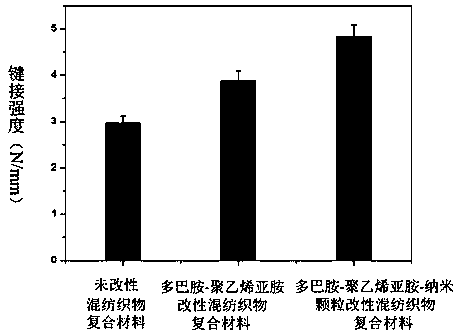

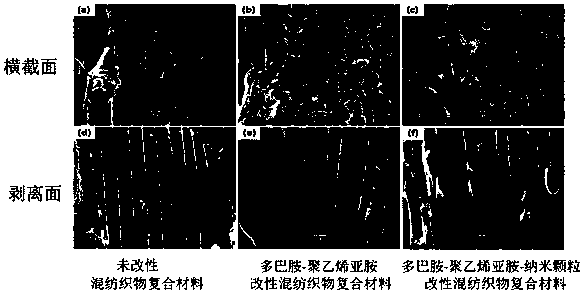

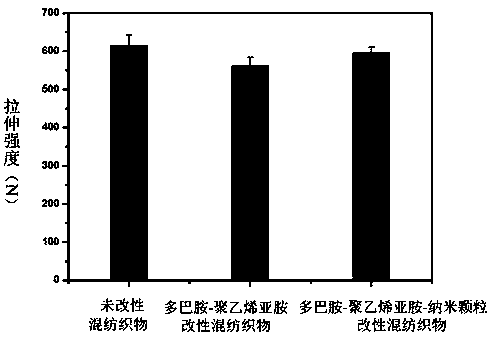

[0027] Take 1270 mg of polytetrafluoroethylene-aramid fiber blended fabric (3 cm × 12 cm), 120 mg of dopamine hydrochloride, 120 mg of polyethyleneimine, and 2 mg of carbon nanotubes, and add them to 60 mL of trimethylol-aminomethane / In a hydrochloric acid buffer solution (pH = 8.5, 20 mmol / L), stir and ultrasonically disperse evenly; then transfer the above mixed solution to an open flask, and continue to stir and react at room temperature for 8 h; after the reaction is completed, the blended The fabric was taken out, fully washed with deionized water to remove unreacted impurities on the surface, and then dried in a vacuum oven for 24 hours to obtain a polydopamine-polyethyleneimine-carbon nanotube hybrid functional coating modified polytetrafluoroethylene- Aramid blend fabric. The interfacial bonding strength between the modified PTFE-aramid blended fabric and the resin matrix is 4.4 (N / mm); the tensile strength is 590 (N).

Embodiment 2

[0029] Add 1270 mg of polytetrafluoroethylene-aramid blended fabric (3 cm × 12 cm), 120 mg of dopamine hydrochloride, 120 mg of polyethyleneimine, and 60 mg of silicon carbide nanoparticles into 60 mL of trimethylol-aminomethane / hydrochloric acid buffer solution (pH = 8.5, 20 mmol / L), stirring and ultrasonically dispersing evenly; then the above mixed solution was transferred to an open flask, and stirred continuously at room temperature for 8 h; after the reaction was completed, the The blended fabric was taken out, fully washed with deionized water to remove unreacted impurities on the surface, and then dried in a vacuum oven for 24 h to obtain a polydopamine-polyethyleneimine-nano-silicon carbide hybrid functional coating modified polytetrafluoroethylene Vinyl-aramid blend fabric. The interfacial bonding strength between the modified PTFE-aramid blended fabric and the resin matrix is 4.2 (N / mm); the tensile strength is 605 (N).

Embodiment 3

[0031]Add 1270 mg of polytetrafluoroethylene-aramid blended fabric (3 cm × 12 cm), 180 mg of dopamine hydrochloride, 180 mg of polyethyleneimine, and 180 mg of zinc oxide nanoparticles into 60 mL of trimethylol-aminomethane / hydrochloric acid buffer solution (pH = 8.5, 20 mmol / L), stirring, and ultrasonic dispersion; then transfer the above mixed solution to an open flask, and continue to stir and react at room temperature for 12 h; after the reaction is completed, put The blended fabric was taken out, fully washed with deionized water to remove unreacted impurities on the surface, and then dried in a vacuum oven for 24 h to obtain a polydopamine-polyethyleneimine-nanometer zinc oxide hybrid functional coating modified polytetrafluoroethylene Vinyl-aramid blend fabric. The interfacial bonding strength between the modified PTFE-aramid blended fabric and the resin matrix is 4.16 (N / mm); the tensile strength is 611 (N).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com