Catalyst for synthesizing methanol through hydrogenation of carbon dioxide

A technology for carbon dioxide and methanol synthesis, applied in the field of energy chemistry, can solve the problems of high price of metal Pd, difficult industrial process, sintering deactivation, etc., and achieve the effects of good environmental value, low production cost, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Seal 20ml aqueous solution of 0.73mmol ammonium molybdate and 10ml carbon disulfide into a 40ml autoclave under nitrogen protection;

[0019] 2. Keep the autoclave in (1) at 400°C for 4 hours to obtain a sample solution;

[0020] 3. Treat the sample solution obtained in (2) with 30% (mass concentration) ammonia solution for 3 hours, then wash with water and ethanol several times respectively and suction filter to obtain the sample;

[0021] 4. Dry the sample obtained in (3) at 100° C. for 12 hours to obtain a catalyst Cat1 sample.

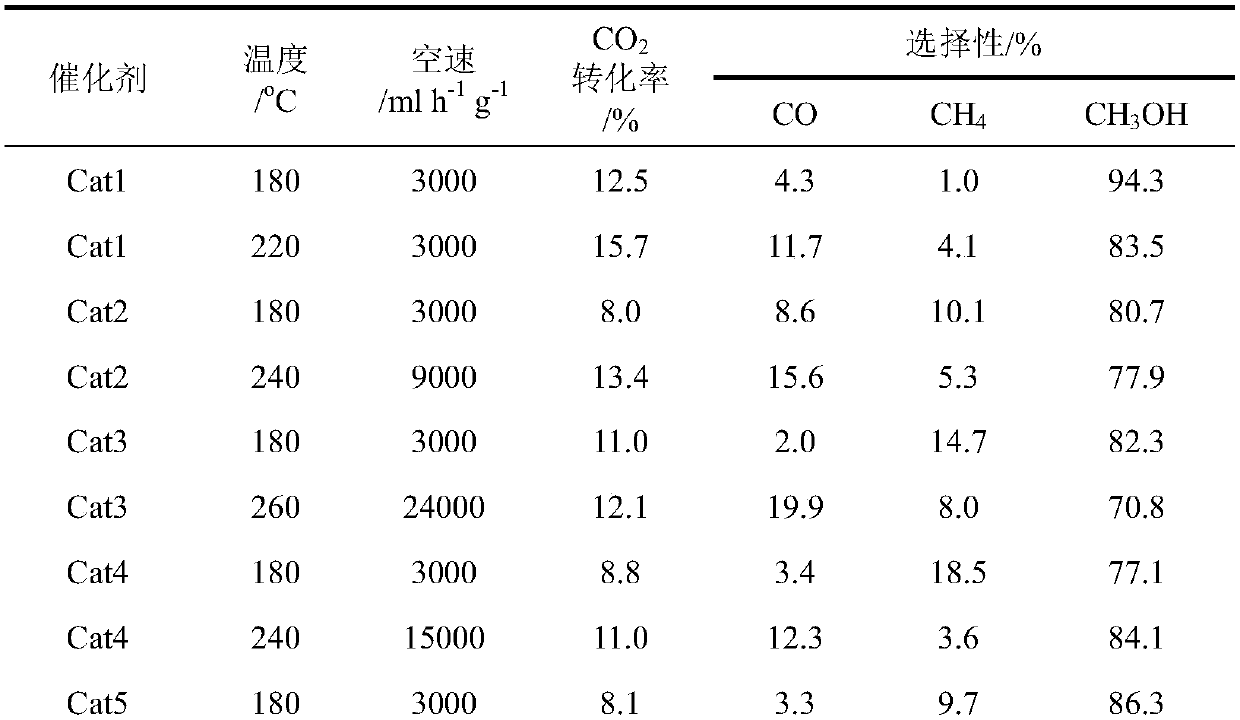

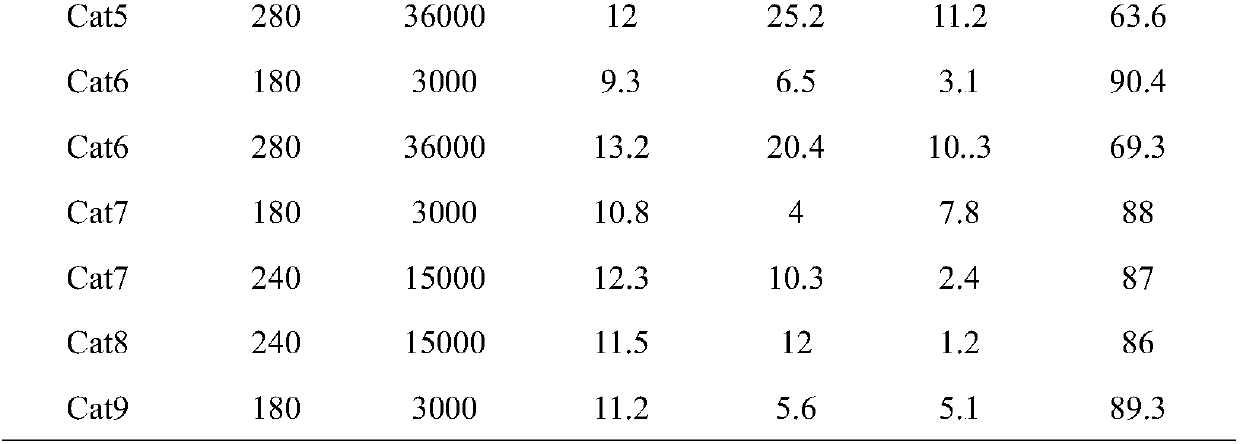

[0022] For the convenience of comparison, the application evaluation conditions and results of the carbon dioxide to methanol application of the catalyst are summarized in the application example, and the evaluation results are listed in Table 1.

Embodiment 2

[0024] 1. Seal 0.73mmol ammonium molybdate and 10ml carbon disulfide into a 40ml autoclave under nitrogen protection;

[0025] 2. Keep the autoclave in (1) at 400°C for 4 hours to obtain a sample solution;

[0026] 3. Dissolve the sample solution obtained in (2) in 6mol L -1 The NaOH solution was treated for 3 hours, then washed with water and ethanol several times and suction filtered to obtain the sample;

[0027] 4. Dry the sample obtained in (3) at 100° C. for 12 hours to obtain a catalyst Cat2 sample.

[0028] For the convenience of comparison, the application evaluation conditions and results of the carbon dioxide to methanol application of the catalyst are summarized in the application example, and the evaluation results are listed in Table 1.

Embodiment 3

[0030] 1. Dissolve 1mmol ammonium molybdate and 30mmol thiourea in 35ml water, and seal it into a 100ml reaction kettle under nitrogen protection;

[0031] 2. Keep the reaction kettle in (1) at 200°C for 24 hours to obtain a sample solution;

[0032] 3. Dissolve the sample solution obtained in (2) in 6mol L -1 The KOH solution was treated for 3 hours, then washed with water and ethanol several times and suction filtered to obtain the sample;

[0033] 4. Dry the sample obtained in (3) at 100° C. for 12 hours to obtain a catalyst Cat3 sample.

[0034] For the convenience of comparison, the application evaluation conditions and results of the carbon dioxide to methanol application of the catalyst are summarized in the application example, and the evaluation results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com