A cross-linking modification method to maintain the original shape of linear polystyrene materials

A linear polystyrene, cross-linking modification technology, applied in fiber treatment, synthetic fibers, textiles and papermaking, etc., can solve problems affecting microscopic morphology and structure, reduce pre-crosslinking reaction rate, prolong reaction time, etc. Achieve the effects of wide range of shapes, perfect shape maintenance, and low raw material prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A cross-linking modification method for maintaining the original shape of a linear polystyrene material, the steps are as follows:

[0029] (1) Preparation of the mixed solution: Add 40 mL of n-hexane, 5 mL of diethoxymethane and 2 g of ferric chloride into a 100 mL beaker in sequence, seal it with plastic wrap, and stir and mix at room temperature for 10 min. After the stirring finishes, take the supernatant to obtain a mixed solution;

[0030] (2) Cross-linking modification of the linear polystyrene hollow fiber membrane: sandwich the linear polystyrene hollow fiber membrane between two layers of polyethylene mesh and fix it, put it into the mixed solution obtained in step (1), and heat it at 30 The reaction was stirred at ℃ for 1 h. After the reaction, the product was washed with water and absolute ethanol respectively, and dried to obtain the target product.

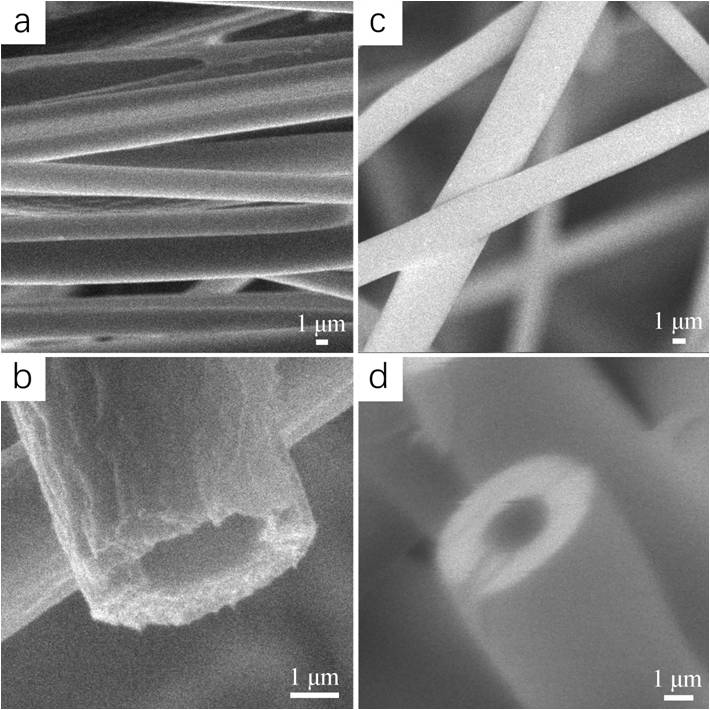

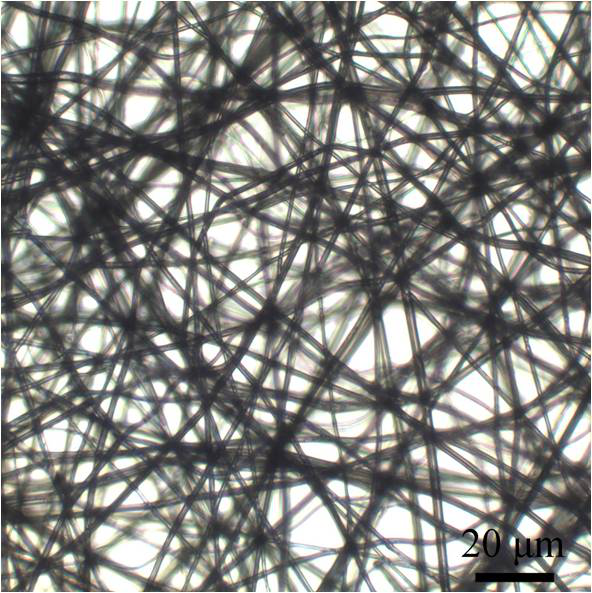

[0031] FESEM images of linear polystyrene hollow fiber membranes (a, b) and target products (c, d) are sho...

Embodiment 2

[0037] The difference from Example 1 is that the "linear polystyrene hollow fiber membrane" in step (2) is changed to "linear polystyrene nanospheres (1 g)", and the linear polystyrene nanospheres are directly The spheres were added to the mixed solution obtained in step (1), and reacted at 60 °C for 48 h; the rest of the steps were the same as in Example 1.

[0038] The FESEM photo of the target product is shown in Figure 7 . Figure 7 It shows that after crosslinking, the spherical shape of the linear polystyrene nanospheres is well maintained, preventing the deformation and adhesion of the balls, indicating that the method of the present invention successfully realizes the crosslinking modification of the linear polystyrene nanospheres.

Embodiment 3

[0040] The difference from Example 1 is that the "linear polystyrene hollow fiber membrane" in step (2) is changed to "linear polystyrene spin-coated film", and the linear polystyrene spin-coated film is directly placed in the step (1) In the obtained mixed solution, react at 0°C for 24 h; the rest of the steps are the same as in Example 1.

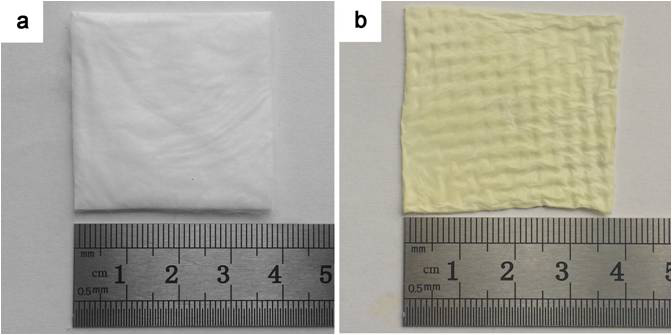

[0041] Digital photographs of the linear polystyrene spin-coated film (a) and the target product (b) are shown in Figure 8 . Figure 8 It is shown that after crosslinking, the crosslinked polystyrene film maintains the morphology and integrity of the linear polystyrene spin-coated film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com