Polycaprolactam-coated CoFe2O4 loaded porous carbon negative electrode material and preparation method thereof

A technology of polycaprolactam and negative electrode materials, applied in the preparation/purification of carbon, negative electrodes, battery electrodes, etc., can solve the problems of low conductivity and poor cycle stability of negative electrode materials, and achieve enhanced electrochemical activity and high porosity , The effect of enhancing the magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

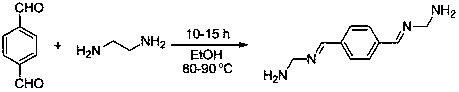

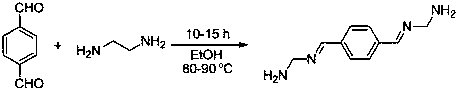

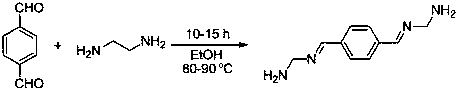

Image

Examples

preparation example Construction

[0024] Polycaprolactam coated CoFe 2 o 4 The hollow microsphere preparation method comprises the following steps:

[0025] (1) Add appropriate amount of ethylene glycol and distilled water to the reaction flask, the volume ratio of the two is 2-3:1, and add Co(NO 3 ) 2 , 1,1'-ferrocenedicarboxylic acid and caprolactam, the molar ratio of the three substances is 1-1.2:1:3-5, transfer the solution into a hydrothermal automatic reaction kettle, and heat to 220-230 ℃ , stirring at a constant speed for 25-30 h.

[0026] (2) Cool the solution to room temperature, remove the upper solution by centrifugation through a high-speed centrifuge, wash the solid product with an appropriate amount of distilled water and absolute ethanol in sequence, and heat it to 70-80 ℃ in a blower dryer to fully dry , to prepare Co-Fe coordination polymer coated with polycaprolactam.

[0027] (3) Place the polycaprolactam-coated Co-Fe coordination polymer in a resistance furnace at a heating rate of 5...

Embodiment 1

[0034] (1) Preparation of polycaprolactam-coated Co-Fe coordination polymer 1: Add appropriate amount of ethylene glycol and distilled water to the reaction flask, the volume ratio of the two is 2:1, and add Co(NO 3 ) 2 , 1,1'-ferrocenedicarboxylic acid and caprolactam, the molar ratio of the three substances is 1:1:3, the solution is transferred into a hydrothermal automatic reaction kettle, heated to 220 ℃, and stirred at a constant speed for 25 h , the solution was cooled to room temperature, and the upper layer solution was removed by centrifugation through a high-speed centrifuge, and the solid product was washed with an appropriate amount of distilled water and absolute ethanol in sequence, and placed in a blast dryer and heated to 70 ° C to fully dry to prepare the poly Caprolactam coated Co-Fe coordination polymer 1.

[0035] (2) Preparation of polycaprolactam-coated CoFe 2 o 4 Hollow microsphere component 1: Preparation Put polycaprolactam-coated Co-Fe coordination...

Embodiment 2

[0040] (1) Preparation of polycaprolactam-coated Co-Fe coordination polymer 2: add appropriate amount of ethylene glycol and distilled water to the reaction flask, the volume ratio of the two is 2:1, add Co(NO 3 ) 2 , 1,1'-ferrocenedicarboxylic acid and caprolactam, the molar ratio of the three substances is 1:1:5, the solution is transferred into a hydrothermal automatic reaction kettle, heated to 220 ℃, and stirred at a constant speed for 30 h , the solution was cooled to room temperature, and the upper layer solution was removed by centrifugation through a high-speed centrifuge, and the solid product was washed with an appropriate amount of distilled water and absolute ethanol in sequence, and placed in a blast dryer and heated to 80 ° C to fully dry to prepare the poly Co-Fe coordination polymer 2 coated with caprolactam.

[0041] (2) Preparation of polycaprolactam-coated CoFe 2 o 4 Hollow microsphere component 2: Preparation Place polycaprolactam-coated Co-Fe coordinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com