Fluorination catalyst precursor and preparation method of fluorination catalyst

A technology of fluorination catalyst and precursor is applied in the field of preparation of fluorination catalyst precursor and fluorination catalyst, and can solve the problems of activity decline, catalyst carbonization and crystal sintering, catalyst metal poisoning and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

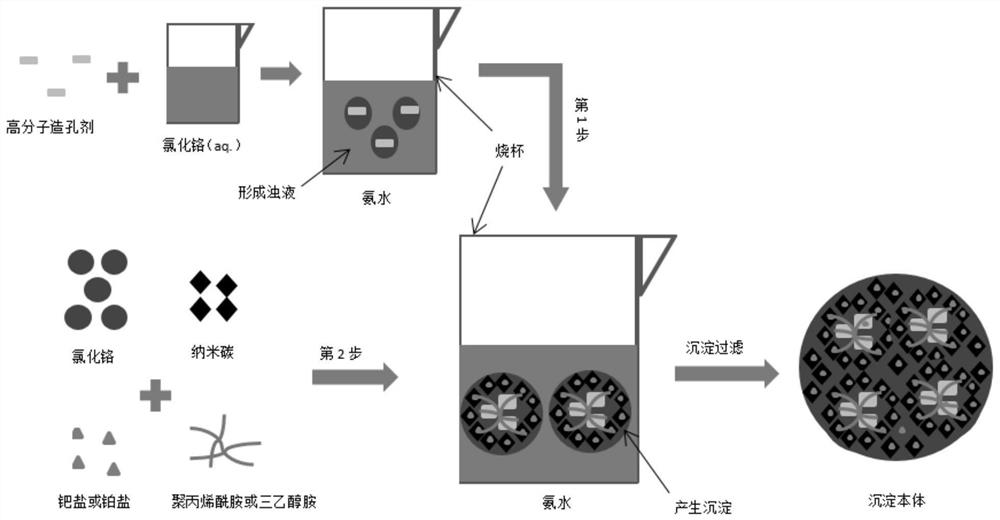

[0032] 1. Preparation of macroporous carrier: First, at least one of lignin, cellulose, lignosulfonate or starch is added to a 5% chromium chloride solution, and fully stirred at a speed of 45 r / min to obtain mixture. Then, the mixed solution is added to 6% ammonia water to obtain a mixed solution containing macroporous carriers, and the volume ratio of the chromium chloride solution to the ammonia water is 1:10-2:5.

[0033]2. Preparation of mesoporous carrier and loading of active metals: chromium chloride, nano-carbon (2-50nm), soluble platinum salt or soluble palladium salt, polyacrylamide or triethanolamine in a mass fraction of 82-93%, 3 Add -10%, 1-6%, 0.5-5% to pure water, stir and mix evenly, then add the above mixture containing macroporous carrier, adjust the speed to 30r / min, maintain aging for 15min, then filter , the filter cake was washed to neutrality.

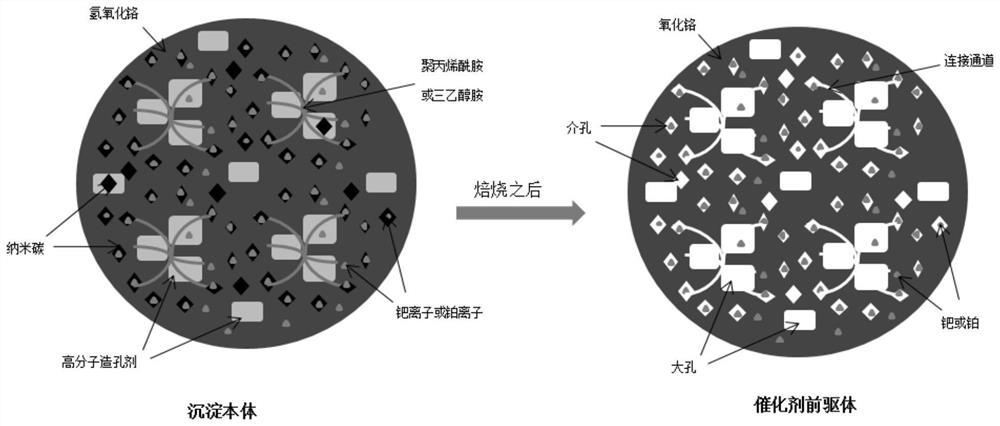

[0034] 3. Catalyst molding: place the filter cake in step 2 in an oven under nitrogen atmosphere for 8-24 ...

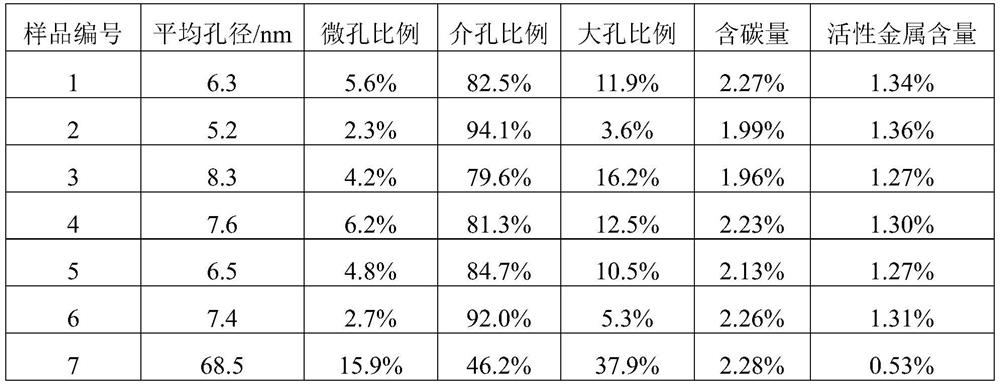

Embodiment 1

[0040] 1. Preparation of macroporous carrier: First, 290 g of lignin was weighed into 3 L of 5% chromium chloride solution, and the mixture was fully stirred at a speed of 45 r / min. Then, the chromium chloride solution mixed with lignin was added to 11 L of ammonia water with a concentration of 6% to obtain a mixed solution containing a macroporous carrier.

[0041] 2. Preparation of mesoporous carrier and loading of active metals: Chromium chloride (1.4Kg), nano-carbon (2-50nm), ammonium tetrachloroplatinate, and polyacrylamide in mass fractions of 91%, 4.5%, 2.7% % and 1.8% were mixed into 26L of pure water, stirred and mixed evenly, then added the mixture containing the macroporous carrier, adjusted the rotation speed to 30r / min, maintained aging for 15min, filtered, and washed the filter cake to neutrality .

[0042] 3. Catalyst molding: place the filter cake in step 2 in an oven under a nitrogen atmosphere, heat it at 120 °C for 12 hours, and put it into a roaster after ...

Embodiment 2

[0044] 1. Preparation of macroporous carrier: First, 290 g of sodium lignosulfonate was weighed and added to 3 L of 5% chromium chloride solution, and the mixture was fully stirred at a speed of 45 r / min. Then, the chromium chloride solution mixed with sodium lignosulfonate was added to 11 L of ammonia water with a concentration of 6% to obtain a mixed solution containing a macroporous carrier.

[0045] 2. Preparation of mesoporous carrier and loading of active metals: Chromium chloride (1.4Kg), nano-carbon (2-50nm), ammonium hexachloroplatinate, and polyacrylamide were mixed with mass fractions of 91%, 4.5%, 2.7% , 1.8%, mixed into 26L of pure water, stirred and mixed evenly, then added the mixture containing the macroporous carrier, adjusted the rotation speed to 30r / min, maintained aging for 15min, filtered, and washed the filter cake to neutrality.

[0046] 3. Catalyst molding: place the filter cake in step 2 in an oven under a nitrogen atmosphere, heat it at 120 °C for 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com