Fluorination catalyst precursor and preparation method of fluorination catalyst

A technology of fluorination catalyst and precursor, which is applied in the field of preparation of fluorination catalyst precursor and fluorination catalyst, can solve the problems of catalyst carbonization and crystal sintering, activity decline, catalyst metal poisoning, etc., and achieves the effect of improving reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

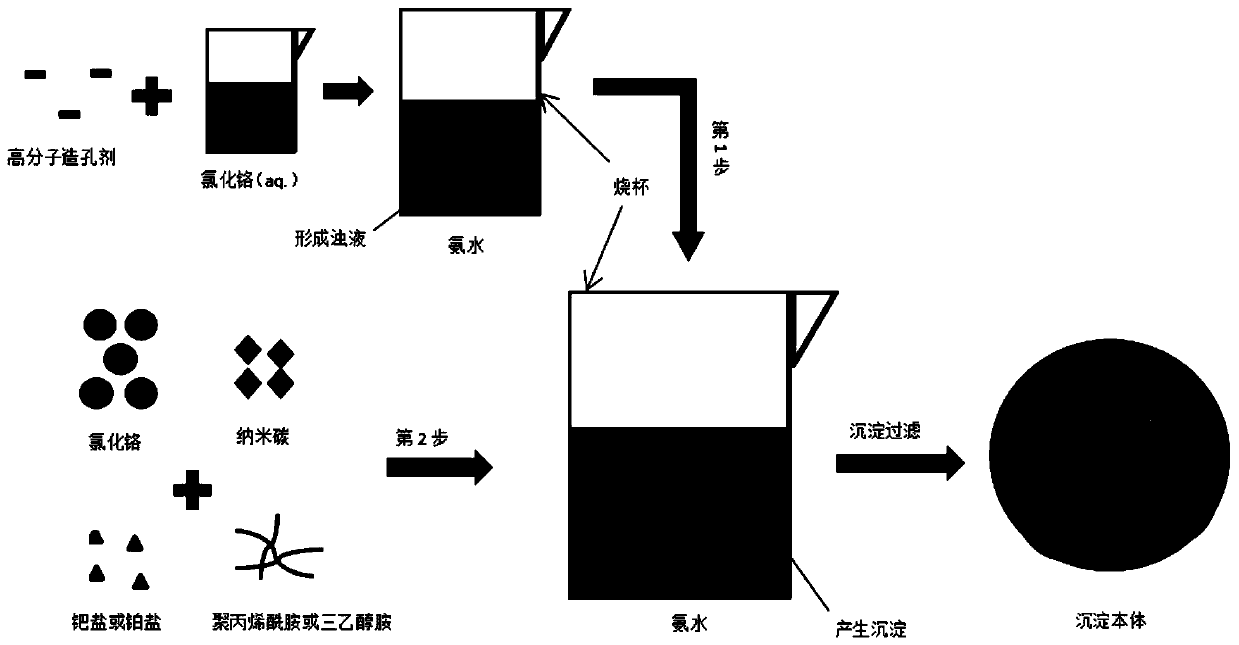

[0032] 1. Preparation of macroporous carrier: First, add at least one of lignin, cellulose, lignosulfonate or starch into a chromium chloride solution with a concentration of 5%, and fully stir at a speed of 45r / min to obtain mixture. Then, the mixed solution is added to 6% ammonia water to obtain a mixed solution containing a macroporous carrier, and the volume ratio of the chromium chloride solution to the ammonia water is 1:10-2:5.

[0033]2. Preparation of mesoporous carrier and loading of active metal: chromium chloride, nano-carbon (2-50nm), soluble platinum salt or soluble palladium salt, polyacrylamide or triethanolamine with a mass fraction of 82-93%, 3 Mix -10%, 1-6%, 0.5-5% into pure water, stir and mix evenly, then add the above mixed solution containing macroporous carrier, adjust the speed to 30r / min, maintain aging for 15min, then filter , wash the filter cake to neutral.

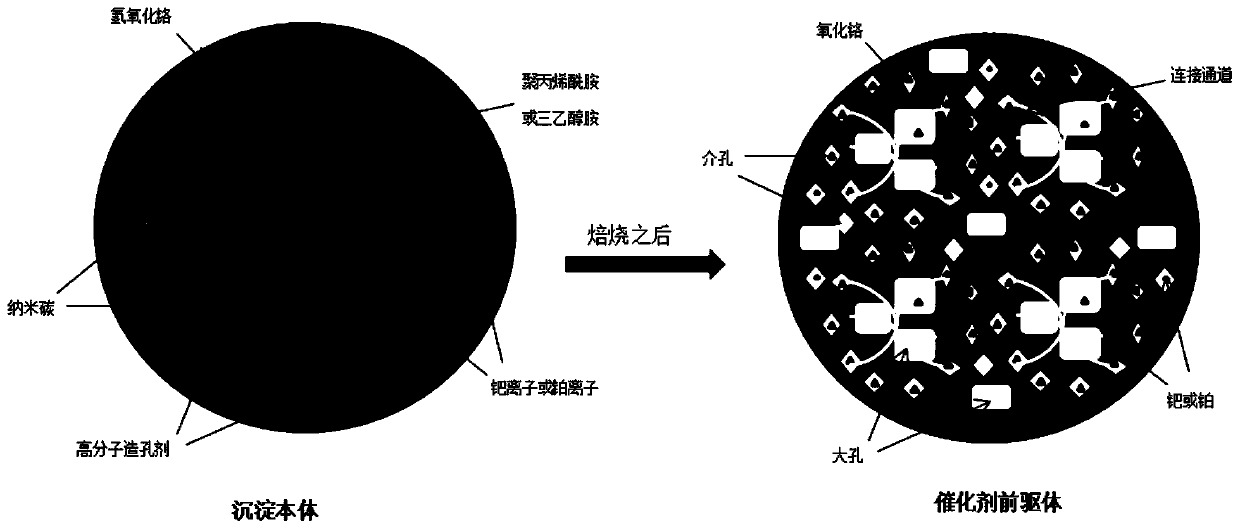

[0034] 3. Catalyst molding: place the filter cake in step 2 in an oven under nitrogen a...

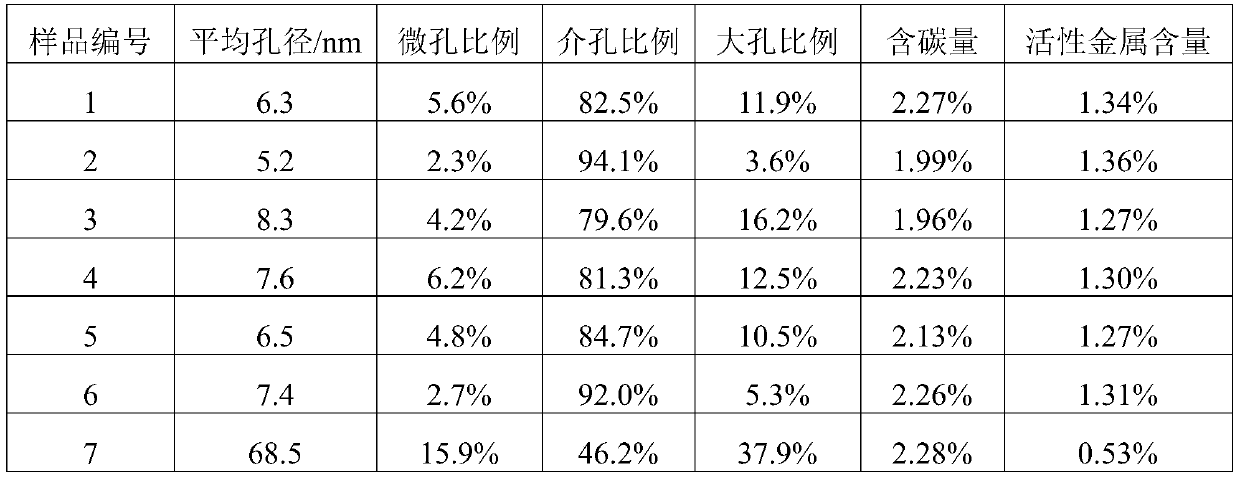

Embodiment 1

[0040] 1. Preparation of the macroporous carrier: First, weigh 290 g of lignin and add it to 3 L of 5% chromium chloride solution, and fully stir at a speed of 45 r / min. Then, the chromium chloride solution mixed with lignin was added to 11 L of 6% ammonia water to obtain a mixed solution containing a macroporous carrier.

[0041] 2. Preparation of mesoporous carrier and loading of active metal: 91%, 4.5%, 2.7 % and 1.8% in 26L of pure water, stirred and mixed evenly, then added the above-mentioned mixed solution containing macroporous carrier, adjusted the speed to 30r / min, maintained aging for 15min, filtered, and washed the filter cake to neutral .

[0042] 3. Catalyst molding: place the filter cake in step 2 in an oven under a nitrogen atmosphere to heat and dry at 120°C for 12 hours, and put it into a roasting furnace after drying for H 2 Baking at 450°C for 8h under atmosphere. After the calcination is completed, pulverize and add a small amount of graphite for tablet...

Embodiment 2

[0044] 1. Preparation of macroporous carrier: First, weigh 290 g of sodium lignosulfonate and add it into 3 L of 5% chromium chloride solution, and fully stir at a speed of 45 r / min. Then, the chromium chloride solution mixed with sodium lignosulfonate was added to 11 L of 6% ammonia water to obtain a mixed solution containing a macroporous carrier.

[0045] 2. Preparation of mesoporous carrier and loading of active metal: chromium chloride (1.4Kg), nano-carbon (2-50nm), ammonium hexachloroplatinate, polyacrylamide with mass fraction of 91%, 4.5%, 2.7% , 1.8% mixed into 26L pure water, stirred and mixed evenly, then added the above-mentioned mixed solution containing macroporous carrier, adjusted the rotation speed to 30r / min, maintained aging for 15min, filtered, and washed the filter cake until neutral.

[0046] 3. Catalyst molding: place the filter cake in step 2 in an oven under a nitrogen atmosphere to heat and dry at 120°C for 12 hours, and put it into a roasting furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com