Lead lanthanum zirconate titanate ceramic powder as well as preparation method and application thereof

A technology of lead lanthanum zirconate titanate and ceramic powder, which is applied in the field of lead lanthanum zirconate titanate ceramic powder and its preparation, can solve the problems of low precursor concentration, long reaction time, and easy agglomeration of powder, and achieve powder High purity, uniform crystal grains, and high sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

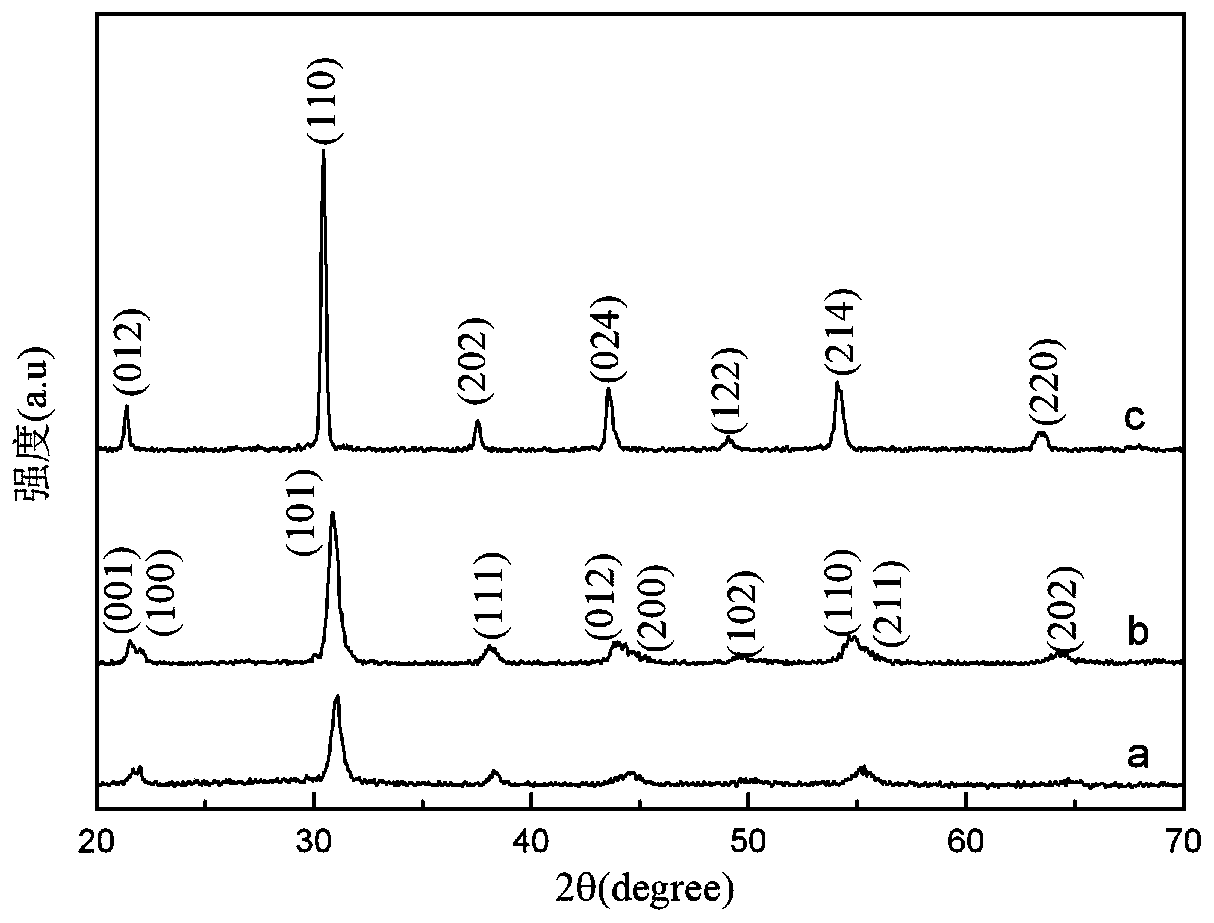

Examples

Embodiment 1

[0034] 1. According to Pb 0.94 La 0.06 Zr 0.52 Ti 0.48 Accurate stoichiometric ratio, weigh 17.7390g of lead acetate and 0.8543g of lanthanum acetate, pour it into 30ml of deionized water, and magnetically stir for 10min under heating in a water bath at 75°C to obtain an aqueous solution of lead and lanthanum;

[0035] 2. Weigh 10.9501g of zirconium n-propoxide and 7.5015g of tetrabutyl titanate into 30ml of absolute ethanol, and magnetically stir for 20min under heating in a water bath at 75°C to obtain a zirconium-titanium alcohol solution;

[0036] 3. Pour the zirconium-titanium alcohol solution into the lead-lanthanum aqueous solution, stir magnetically for 20 minutes under heating in a water bath at 75°C, and cool to room temperature to prepare a lead-lanthanum zirconate titanate mixture;

[0037] 4. In order to make the concentration of potassium hydroxide in the prepared precursor solution 2mol / L, weigh 6.2345g of potassium hydroxide and pour it into the lead zircona...

Embodiment 2

[0041] 1. According to Pb 0.94 La 0.06 Zr 0.63 Ti 0.37 Accurate stoichiometric ratio Weigh 17.7390g of lead acetate and 0.8543g of lanthanum acetate into 30ml of deionized water, and magnetically stir for 10min under heating in a water bath at 75°C to obtain an aqueous solution of lead and lanthanum;

[0042] 2. Weigh 13.2665g of zirconium n-propoxide and 5.7824g of tetrabutyl titanate into 30ml of absolute ethanol, and stir magnetically for 20min under heating in a water bath at 75°C to prepare a zirconium-titanium alcohol solution;

[0043] 3. Pour the zirconium-titanium alcohol solution into the lead-lanthanum aqueous solution, stir magnetically for 20 minutes under heating in a water bath at 75°C, and cool to room temperature to prepare a lead-lanthanum zirconate titanate mixed solution;

[0044] 4. In order to make the concentration of potassium hydroxide in the prepared precursor solution 3mol / L, weigh 9.3517g of potassium hydroxide and pour it into the lead zirconate...

Embodiment 3

[0048] 1. According to Pb 0.94 La 0.06 Zr 0.95 Ti 0.05 Accurate stoichiometric ratio Weigh 17.7390g of lead acetate and 0.8543g of lanthanum acetate into 30ml of deionized water, and magnetically stir for 10min under heating in a water bath at 75°C to obtain an aqueous solution of lead and lanthanum;

[0049] 2. Weigh 20.0050g of zirconium n-propoxide and 0.7814g of tetrabutyl titanate into 30ml of absolute ethanol, and stir magnetically for 20min under heating in a water bath at 75°C to prepare a zirconium-titanium alcohol solution;

[0050] 3. Pour the zirconium-titanium alcohol solution into the lead-lanthanum aqueous solution, stir magnetically for 20 minutes under heating in a water bath at 75°C, and cool to room temperature to prepare a lead-lanthanum zirconate titanate mixed solution;

[0051] 4. In order to make the concentration of potassium hydroxide in the prepared precursor solution 3mol / L, weigh 9.3517g of potassium hydroxide and pour it into the lead zirconate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com