Method for modifying environment-friendly wood lacquer by using nanometer zinc oxide-polyethylene wax microcapsules

A technology of nano-zinc oxide and polyethylene wax, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of low hardness, poor wear resistance, poor water resistance, etc., and achieve smooth surface, improved wear resistance and water resistance , improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

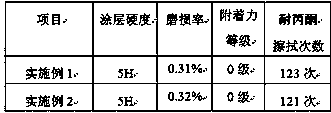

Examples

Embodiment 1

[0023] A method for modifying environment-friendly wood lacquer with nanometer zinc oxide-polyethylene wax microcapsules, characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0024] (1) Use citric acid monohydrate to modify the surface of nano-zinc oxide:

[0025] Add deionized water / ethanol solution to 1 part of nano-zinc oxide at 1:100, and ultrasonically obtain nano-zinc oxide suspension; dissolve 0.1 part of citric acid monohydrate in 100 parts of deionized water / ethanol solution, and use Adjust the pH of the solution to 7-8, add dropwise to the nano-zinc oxide suspension, stir magnetically in an oil bath at 35-40°C for 1 hour, wash with ethanol three times, centrifuge for 15 minutes, and dry in vacuum at 60-65°C for 20 hours. Obtain surface-modified nano zinc oxide;

[0026] Wherein, the deionized water / ethanol volume ratio of deionized water / ethanol solution is 8:2;

[0027] (2) Preparation of calc...

Embodiment 2

[0035] A method for modifying environment-friendly wood lacquer with nanometer zinc oxide-polyethylene wax microcapsules, characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0036] (1) Use citric acid monohydrate to modify the surface of nano-zinc oxide:

[0037] Add deionized water / ethanol solution to 2 parts of nano-zinc oxide at 1:100, and ultrasonically obtain a nano-zinc oxide suspension; dissolve 0.2 parts of citric acid monohydrate in 100 parts of deionized water / ethanol solution, and use sodium hydroxide Adjust the pH of the solution to 7-8, add dropwise to the nano-zinc oxide suspension, stir magnetically in an oil bath at 35-40°C for 2 hours, wash with ethanol for 5 times, centrifuge for 20 minutes, and dry in vacuum at 60-65°C for 24 hours. Obtain surface-modified nano zinc oxide;

[0038] Wherein, the deionized water / ethanol volume ratio of deionized water / ethanol solution is 8:2;

[0039] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com