Up-conversion luminescent nanometer material and core-shell type fluorescent nanometer material integrating up-conversion luminescence and down-conversion long afterglow luminescence

A technology of fluorescent nanomaterials and long afterglow luminescence, applied in the field of core-shell fluorescent nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

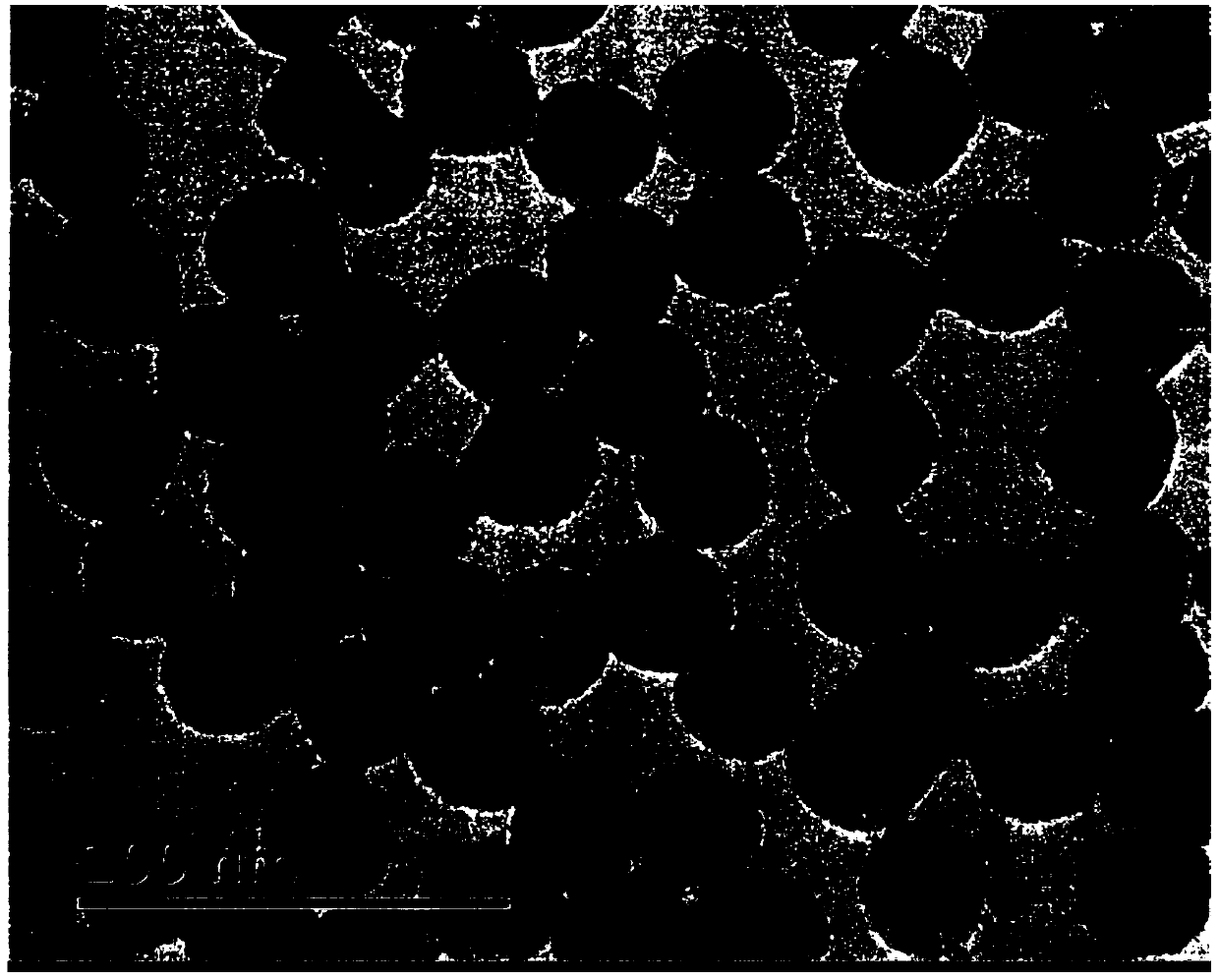

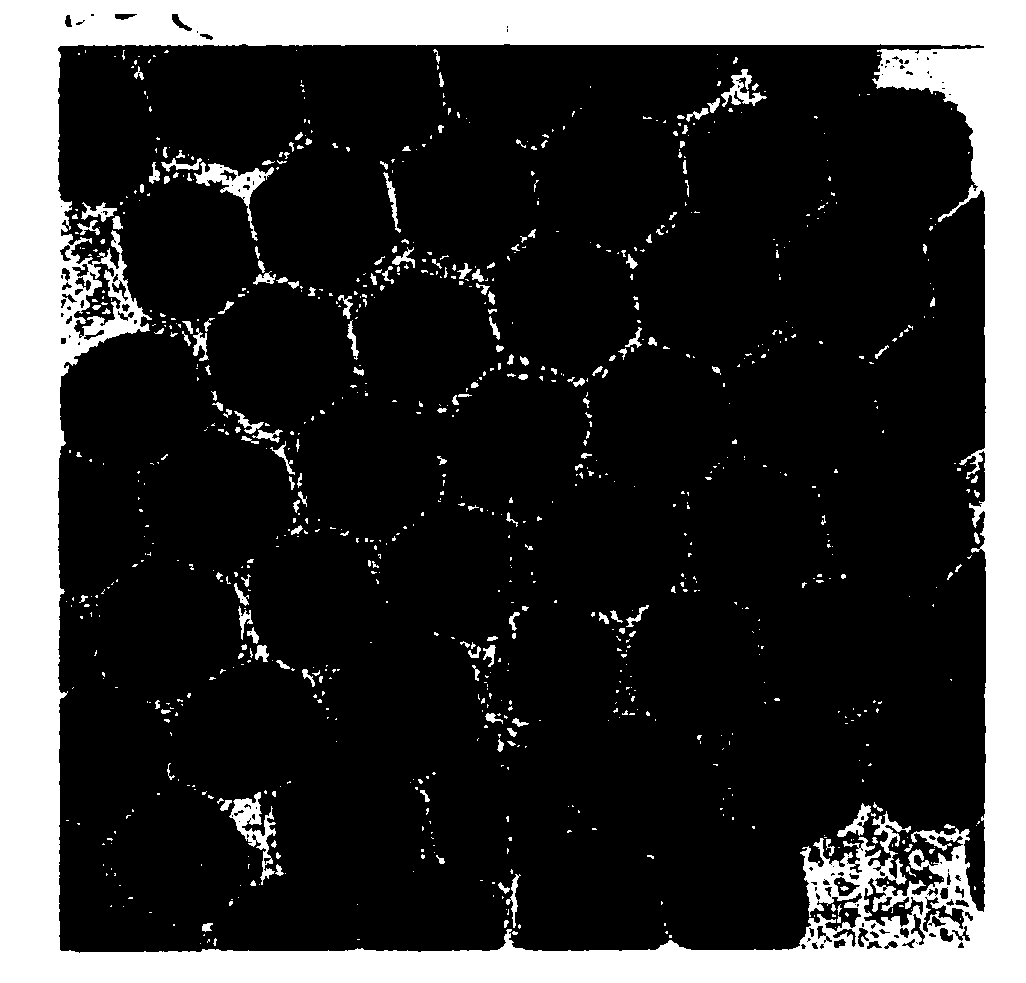

[0046] Example 1: BaSrY 0.95 La 0.05 f 7 :Yb 3+ 0.98 , Er 3+ 0.02 Preparation of nanoparticles:

[0047] Weigh 0.042g BaCl according to the stoichiometric ratio according to the chemical formula 2 , 0.032g SrCl 2 , 0.0004g La 2 o 3 , into a 100ml three-necked flask, 15ml of trifluoroacetic acid was added, the temperature was raised to 50°C, and stirred for 0.5h. Then weigh 0.037gYCl in proportion 3 , 0.055g YbCl 3 , 0.0012g ErCl 3, dissolved in 10ml of deionized water, and added to a three-neck flask, heated to 120°C, added 30ml of oleic acid and 30ml of octadecene, and continued magnetic stirring at 120°C for 0.5h to remove water and oxygen. Under the protection of argon, the above mixed solution was heated to 330° C. at a heating rate of about 8° C. / min, and reacted under vigorous stirring for one hour to fully complete the reaction. During the synthesis, the argon gas was pumped out. The mixture was cooled to room temperature and precipitated by acetone, and ...

Embodiment 2

[0048] Example 2: Ba 1.4 Sr 0.6 Y 0.95 La 0.05 f 7 :Yb 3+ 0.9 , Tm 3+ 0.1 Preparation of nanoparticles

[0049] According to the chemical formula, weigh 0.058g BaCl according to the stoichiometric ratio 2 , 0.019g SrCl 2 , 0.004g La 2 o 3 , into a 100ml three-necked flask, 15ml of trifluoroacetic acid was added, the temperature was raised to 50°C, and stirred for 0.5h. Then weigh 0.037gYCl in proportion 3 , 0.050g YbCl 3 , 0.0055g TmCl 3 , dissolved in 10ml of deionized water, and added to a three-neck flask, heated to 120°C, added 30ml of oleic acid and 30ml of octadecene, and continued magnetic stirring at 120°C for 0.5h to remove water and oxygen. Under the protection of argon, the above mixed solution was heated to 330° C. at a heating rate of about 8° C. / min, and reacted under vigorous stirring for one hour to fully complete the reaction. During the synthesis, the argon gas was pumped out. The mixture was cooled to room temperature and precipitated by ace...

Embodiment 3

[0050] Example 3.BaSrY 0.8 La 0.2 f 7 :Yb 3+ 0.95 , Ho 3+ 0.05 Preparation of nanoparticles

[0051] Weigh 0.042g BaCl according to the stoichiometric ratio according to the chemical formula 2 , 0.032g SrCl 2 , 0.013g La 2 o 3 , into a 100ml three-necked flask, 15ml of trifluoroacetic acid was added, the temperature was raised to 50°C, and stirred for 0.5h. Then weigh 0.031gYCl in proportion 3 , 0.053g YbCl 3 , 0.003g HoCl 3 , dissolved in 10ml of deionized water, and added to a three-neck flask, heated to 120°C, added 30ml of oleic acid and 30ml of octadecene, and continued magnetic stirring at 120°C for 0.5h to remove water and oxygen. Under the protection of argon, the above mixed solution was heated to 330° C. at a heating rate of about 8° C. / min, and reacted under vigorous stirring for one hour to fully complete the reaction. During the synthesis, the argon gas was pumped out. The mixture was cooled to room temperature and precipitated by acetone, and centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com