Preparation method of high-silicon Y-type molecular sieves

A molecular sieve and high-silicon technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of large loss of crystallinity of molecular sieve, difficult to achieve silicon-aluminum ratio, complicated preparation process, etc., to achieve Improve the ion exchange rate, increase the silicon-aluminum ratio, and improve the modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

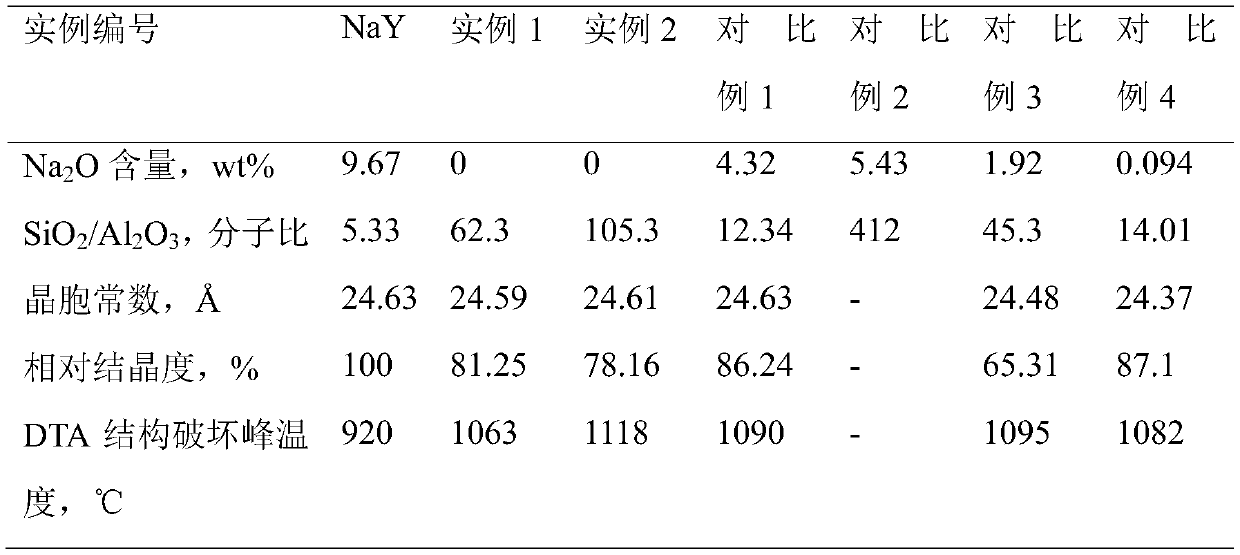

example 1

[0018] Weigh 100g of raw material NaY molecular sieve (produced by Nankai Catalyst Factory, the same below), add 500ml of oxalic acid-ammonium chloride buffer solution (oxalic acid:ammonium chloride:water = 1g:10g:50ml), and stir at 90℃ 5.5h, filter, beat and wash with deionized water, and dry. Then put the obtained Y molecular sieve into a muffle furnace at a temperature of 600 ℃ and roast for 6 hours; repeat the above process once, but the buffer solution of oxalic acid-ammonium chloride (oxalic acid: ammonium chloride: water = 2g:10g:50ml) is selective The Y zeolite for ammonium exchange and removal of part of the framework aluminum; take 50g of the above two-by-two-baked zeolite, add 750ml of 0.5mol / L nitric acid, stir at 80℃ for 3h, filter, beat and wash with deionized water, dry, and then Put the obtained Y molecular sieve into a muffle furnace at a temperature of 600° C. and roast for 6 hours to obtain a high-silicon modified Y molecular sieve. Its physical and chemical...

example 2

[0020] Weigh 100g of the raw material NaY molecular sieve, add 500ml of the prepared citric acid-ammonium nitrate buffer solution (citric acid: ammonium nitrate: water = 2g:6g:50ml), stir at 80℃ for 5.5h, filter, and use deionized water Beating, washing, and drying. Then put the obtained Y molecular sieve into a muffle furnace at a temperature of 800℃ and roast for 4h; repeat the above process once, but the buffer solution of citric acid-ammonium nitrate (citric acid:ammonium nitrate:water=4g:6g:50ml) is selective The Y zeolite for ammonium exchange and removal of part of the framework aluminum; take 50g of the above two-by-two-baked zeolite, add 750ml of 1mol / hydrochloric acid, stir at 80℃ for 6h, filter, wash with deionized water, and dry, and then the obtained The Y molecular sieve is put into a muffle furnace at a temperature of 800° C. and roasted for 4 hours to obtain a high-silicon modified Y molecular sieve. Its physical and chemical properties are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com