Colored granular solid toilet detergent, preparation method thereof, and special containers

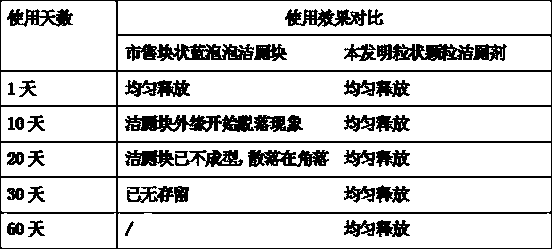

A granular solid and toilet cleaner technology, applied in the preparation of detergent mixture compositions, chemical instruments and methods, detergent materials, etc., can solve the problem of uneven release speed of active ingredients, inability to improve the effect of toilet bowls for a long time, and affect the cleanliness. To achieve the effect of maintaining the toilet cleaning effect for a long time, inhibiting the growth of bacteria, and improving the toilet cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

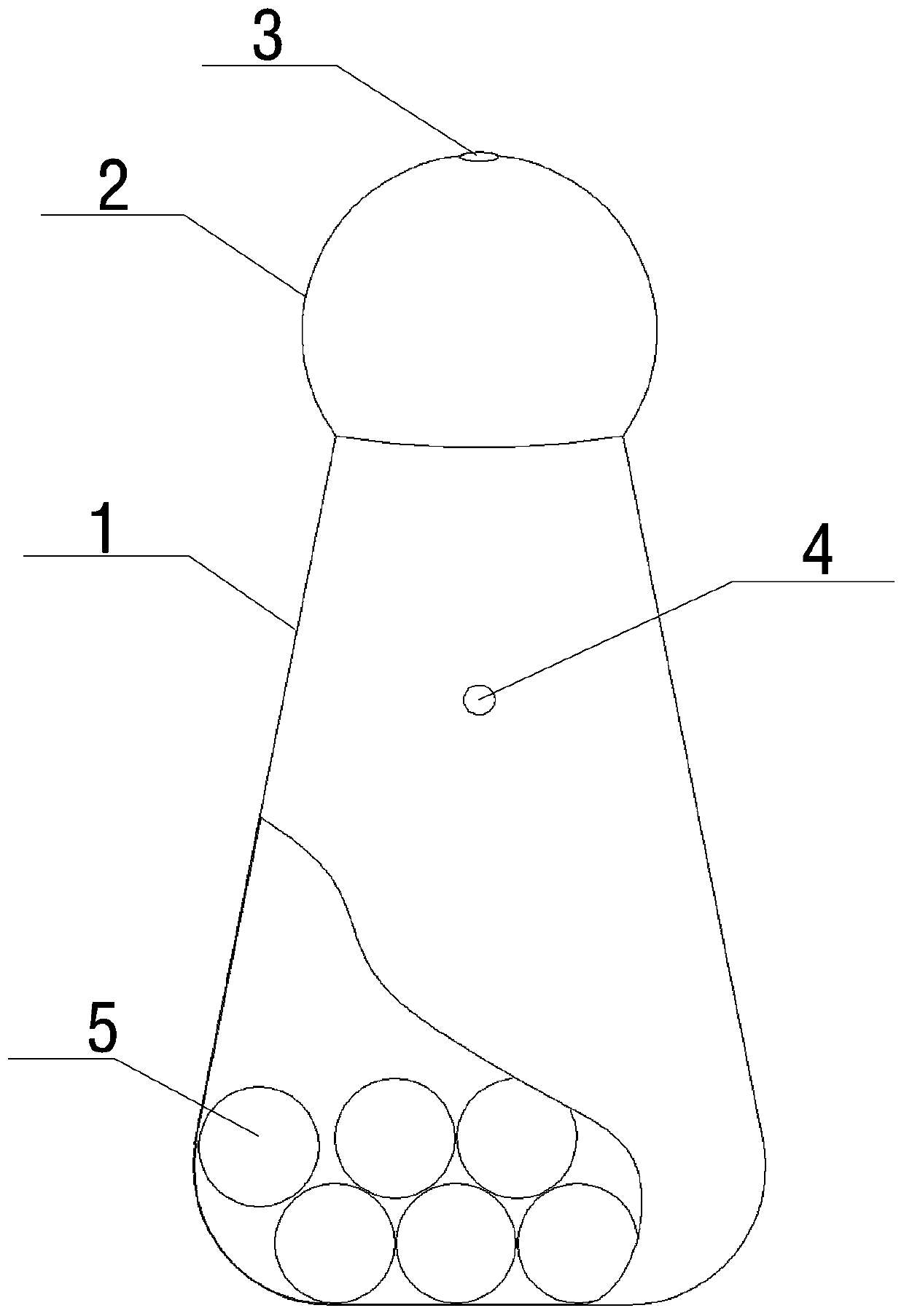

Image

Examples

Embodiment 1

[0027] A kind of colored granular solid toilet cleaning agent of the present invention, it is made of the following components of mass fraction ratio: 40 parts of sodium sulfate, 5 parts of isomeric fatty alcohol polyoxyethylene ether, 5 parts of sodium percarbonate, 3 parts of hydroxypropyl cellulose, 3 parts of edible starch, 5 parts of sodium stearate, 5 parts of deionized water, 1 part of zinc ricinoleate, 1 part of N-alkylpropylaminoglycine, 0.5 1 part of disodium edetate, 0.01 part of food grade bright blue pigment and 0.1 part of pine wood flavor essence.

[0028] The preparation method of above-mentioned a kind of colored granular solid toilet cleaner, it comprises the following steps:

[0029] (1). Weighing the ingredients: each component is weighed according to the proportion, and placed in their respective special containers for use;

[0030] (2). Stirring and mixing: first mix sodium sulfate, sodium percarbonate, hydroxypropyl cellulose, edible starch, sodium stea...

Embodiment 2

[0038] A kind of colored granular solid toilet cleaning agent of the present invention, it is made of the following components of mass fraction ratio: 45 parts of sodium sulfate, 10 parts of isomeric fatty alcohol polyoxyethylene ether, 7 parts of sodium percarbonate, 4 parts of hydroxypropyl cellulose, 5 parts of edible starch, 6 parts of sodium stearate, 7 parts of deionized water, 2 parts of zinc ricinoleate, 2 parts of N-alkylpropylaminoglycine, 0.7 Disodium EDTA, 0.005 part of food grade bright blue pigment and 0.2 part of pine wood flavor.

[0039]The preparation method of above-mentioned a kind of colored granular solid toilet cleaner of the present invention, it comprises the following steps:

[0040] (1). Weighing the ingredients: each component is weighed according to the proportion, and placed in their respective special containers for use;

[0041] (2). Stirring and mixing: first mix sodium sulfate, sodium percarbonate, hydroxypropyl cellulose, edible starch, sodi...

Embodiment 3

[0045] A kind of colored granular solid toilet cleaning agent of the present invention, it is made of the following components of mass fraction ratio: 50 parts of sodium sulfate, 15 parts of isomeric fatty alcohol polyoxyethylene ether, 10 parts of sodium percarbonate, 5 parts of hydroxypropyl cellulose, 7 parts of edible starch, 8 parts of sodium stearate, 10 parts of deionized water, 3 parts of zinc ricinoleate, 3 parts of N-alkylpropylaminoglycine, 1 1 part of disodium edetate, 0.1 part of food grade bright blue pigment and 0.3 part of pine wood flavor essence.

[0046] The preparation method of above-mentioned a kind of colored granular solid toilet cleaner, it comprises the following steps:

[0047] (1). Weighing the ingredients: each component is weighed according to the proportion, and placed in their respective special containers for use;

[0048] (2). Stirring and mixing: first mix sodium sulfate, sodium percarbonate, hydroxypropyl cellulose, edible starch, sodium st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com