Sunscreen bubble taking carbon dioxide as propellant and preparation method thereof

A carbon dioxide and propellant technology, applied in the field of daily chemical products, can solve the problems of storage, transportation and carrying restrictions, inconvenience of large-scale application, high risk of inhalation, etc., to achieve good sunscreen effect, improve user experience, and improve the effect of moisturizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

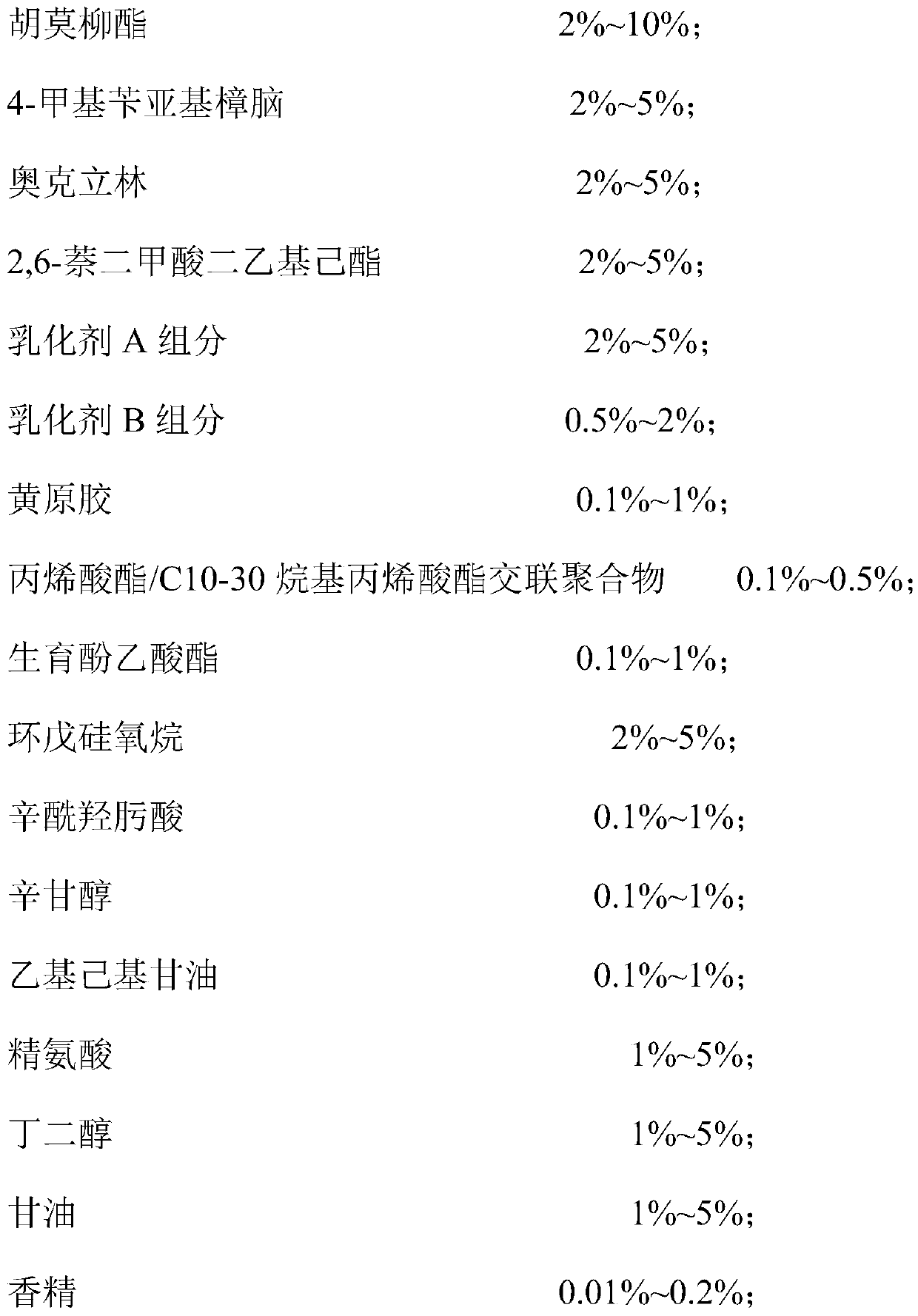

[0030] Formula: Homosalate 3%; 4-Methylbenzylidene Camphor 3%; Octocrylene 4%; Diethylhexyl 2,6-Naphthalate 4%; Glyceryl Oleate Citrate and Caprylic / Capric Triglycerides 3% total; PEG-100 Stearate and Glyceryl Stearate 0.5% total; Xanthan Gum 1%; Acrylates / C10-30 Alkyl Acrylate Crosspolymer 0.5 %; Tocopheryl Acetate 0.1%; Cyclopentasiloxane 5%; Caprylyl Hydroxamic Acid 0.1%; Caprylyl Glycol 0.1%; Ethylhexylglycerin 1%; ; Glycerin 5%; Essence 0.01%; Carbon Dioxide 2%;

[0031] Prepare sunscreen bubbles with carbon dioxide as propellant as follows:

[0032] Step 1, add xanthan gum, acrylate / C10-30 alkyl acrylate crosslinked polymer into glycerin, stir and disperse evenly in advance, and set aside;

[0033] Step 2: Homosalate, 4-methylbenzylidene camphor, octocrylene, 2,6-diethylhexyl naphthalate, PEG-100 stearate, glyceryl stearate, Glyceryl oleate citrate, caprylic / capric triglyceride, tocopheryl acetate, and cyclopentasiloxane were heated to 75°C, dissolved completely, and ...

Embodiment 2

[0037] Formula: Homosalate 10%; 4-Methylbenzylidene Camphor 5%; Octocrylene 5%; Diethylhexyl 2,6-Naphthalate 5%; Glyceryl Oleate Citrate and Caprylic / Capric Triglycerides 5% total; PEG-100 Stearate and Glyceryl Stearate 2% total; Xanthan Gum 0.1%; Acrylates / C10-30 Alkyl Acrylate Crosspolymer 0.1 %; Tocopheryl Acetate 1%; Cyclopentasiloxane 5%; Caprylyl Hydroxamic Acid 0.2%; Caprylyl Glycol 0.2%; Ethylhexylglycerin 0.2%; ; Glycerin 1%; Essence 0.2%; Carbon Dioxide 3%;

[0038] Prepare sunscreen bubbles with carbon dioxide as propellant as follows:

[0039] Step 1, add xanthan gum, acrylate / C10-30 alkyl acrylate crosslinked polymer into glycerin, stir and disperse evenly in advance, and set aside;

[0040] Step 2: Homosalate, 4-methylbenzylidene camphor, octocrylene, 2,6-diethylhexyl naphthalate, PEG-100 stearate, glyceryl stearate, Glyceryl oleate citrate, caprylic / capric triglyceride, tocopheryl acetate, and cyclopentasiloxane were heated to 80°C, dissolved completely, and ...

Embodiment 3

[0044]Formulation: Homosalate 2%; 4-Methylbenzylidene Camphor 2%; Octocrylene 2%; Diethylhexyl 2,6-Naphthalate 2%; Caprylic / Capric Triglyceride 2 %; PEG-100 Stearate 0.5%; Xanthan Gum 0.5%; Acrylates / C10-30 Alkyl Acrylate Crosslinking Polymerization 0.5%; Caprylyl Hydroxamic Acid 1%; Hexylglycerin 1%; Arginine 2%; Butylene Glycol 2.5%; Glycerin 4%; Essence 0.1%; Carbon Dioxide 0.5%; Water balance.

[0045] Prepare sunscreen bubbles with carbon dioxide as propellant as follows:

[0046] Step 1, add xanthan gum, acrylate / C10-30 alkyl acrylate crosslinked polymer into glycerin, stir and disperse evenly in advance, and set aside;

[0047] Step 2: Homosalate, 4-methylbenzylidene camphor, octocrylene, 2,6-diethylhexyl naphthalate, PEG-100 stearate, caprylic / capric triglycerides Heat the ester to 76°C, dissolve completely, and set aside;

[0048] Step 3: Add water and butanediol to the reaction vessel in turn and stir evenly, add the substance obtained in step 1, heat to 80°C, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com