Polyamide composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and polyamide technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of low operating pressure and low removal efficiency, and achieve the effects of saving time, low cost, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment provides a kind of preparation method of polyamide composite nanofiltration membrane, comprises the following steps:

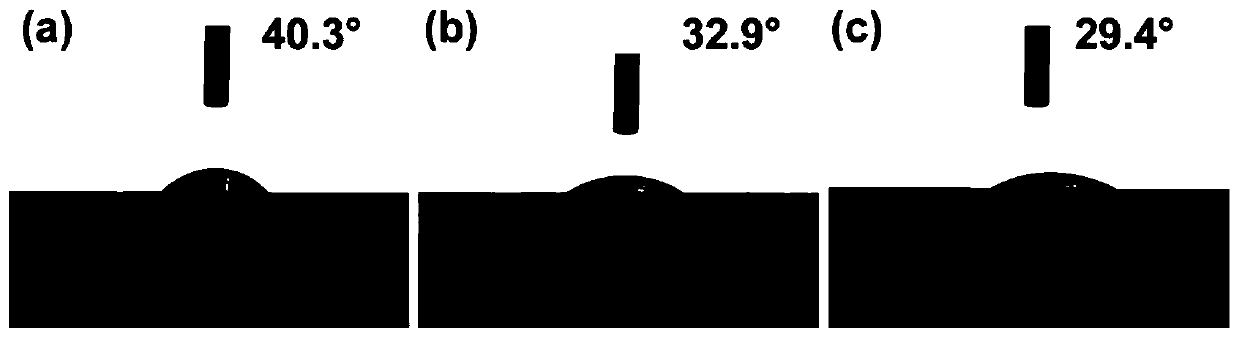

[0027] The first step: prepare the initial polyamide composite nanofiltration membrane; first select a polysulfone ultrafiltration membrane cut into a size of 17cm×10cm, fix it with a polytetrafluoroethylene frame as a support layer, and use the polysulfone ultrafiltration membrane with Rinse carefully with deionized water for 5 minutes; then prepare 50 mL of a mixed aqueous solution with a mass fraction of 0.35% piperazine and 0.24% sodium hydroxide, and stir until fully dissolved. Pour the mixed aqueous solution on the surface of the polysulfone base membrane, soak for 120s, filter off the excess liquid, dry the surface until there are no visible droplets on the surface, and quickly pour the n-hexane solution with a mass fraction of 0.3% trimesoyl chloride 50mL was fully infiltrated, and after the interfacial polymerization reac...

Embodiment 2

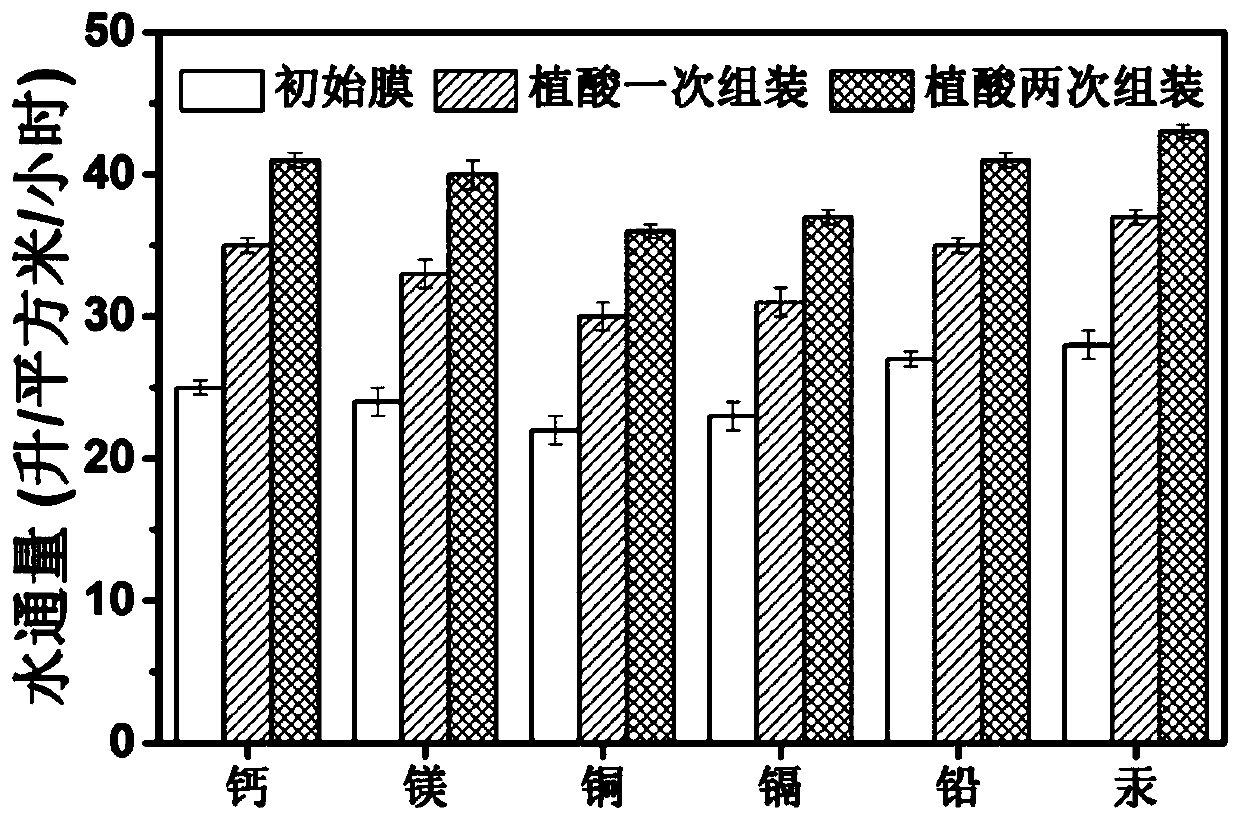

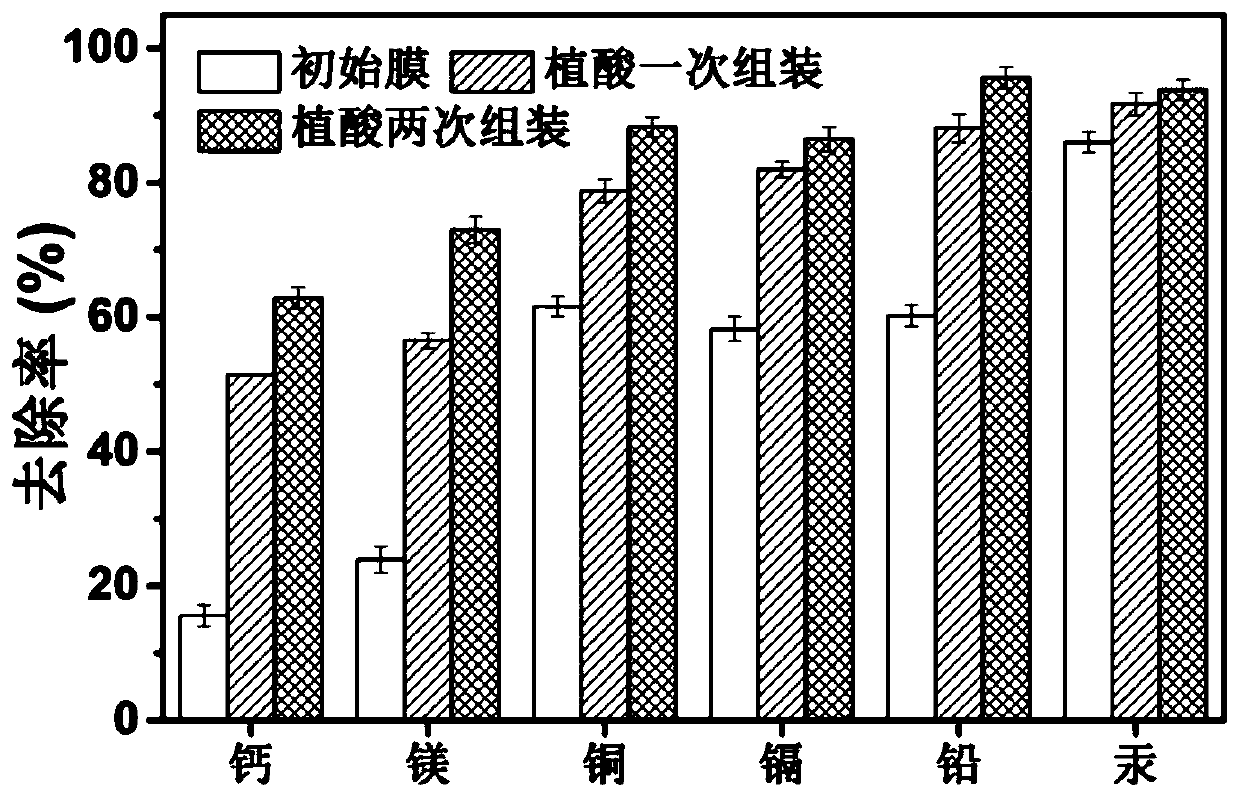

[0034] Prepare the initial polyamide composite nanofiltration membrane according to the steps and conditions given in the first step in Example 1, then configure the polyethyleneimine aqueous solution with a mass fraction of 1%, and mix it with the n-hexane of the remaining unreacted trimesoyl chloride Alkanes solution cross-linking polymerization, graft positively charged polyethyleneimine onto the initial polyamide composite nanofiltration membrane, after 10 minutes, pour off the excess liquid to obtain a polyamide composite nanofiltration membrane with saturated adsorption of polyethyleneimine ; Prepare a phytic acid solution with a mass fraction of 0.08%, and pour it on the polyamide composite nanofiltration membrane saturated with polyethylenimine, interact with positive and negative charges, and carry out an electrostatic assembly. After the assembly is carried out for 20 minutes, remove The excess solution was obtained to obtain a polyamide composite nanofiltration membr...

Embodiment 3

[0037] Prepare the initial polyamide composite nanofiltration membrane according to the steps and conditions given in the first step in Example 1, then configure the polyethyleneimine aqueous solution with a mass fraction of 1%, and mix it with the n-hexane of the remaining unreacted trimesoyl chloride Alkanes solution cross-linking polymerization, graft positively charged polyethyleneimine onto the initial polyamide composite nanofiltration membrane, after 10 minutes, pour off the excess liquid to obtain a polyamide composite nanofiltration membrane with saturated adsorption of polyethyleneimine ; Prepare a phytic acid solution with a mass fraction of 0.08%, and pour it on the polyamide composite nanofiltration membrane saturated with polyethylenimine, interact with positive and negative charges, and carry out an electrostatic assembly. After the assembly is carried out for 20 minutes, remove Excessive solution, obtain the polyamide composite nanofiltration membrane of phytic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com