Preparation method of functional impact-resistant veneer

An impact-resistant and functional technology, applied in the field of wood processing, can solve the problems of affecting the appearance, poor dye fixation rate, and difficulty in ensuring the floor color is durable, so as to improve distribution uniformity and fixation rate, dimensional stability and water resistance Lifting, coloring effect beautiful and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

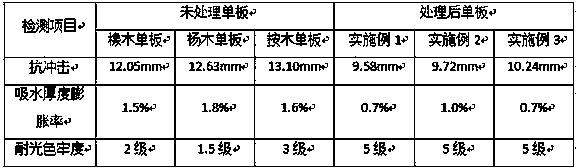

Examples

Embodiment 1

[0028] A method for preparing a functional impact-resistant veneer, comprising the following steps:

[0029] (1) Using sliced oak veneer as raw material, it is dyed, and hindered amine light stabilizer UV-765 and disazoic acid dye C 24 h 22 N 4 o 6 S 2 According to the mass ratio of 15:100, the acidic binary compound dye was prepared, the dye was dissolved at 65°C, and the air pump was turned on at the same time, air was introduced into the dye solution, the dye solution was stirred to make the concentration uniform, the dye was dissolved for 40 minutes, and the oak single The board is vertically immersed in the dyeing solution, bath ratio V solution: V board=8:1, the temperature is raised at a rate of 1°C / min, and the temperature is kept at 90°C for heat preservation dyeing, and the oak veneer is dipped for 4 hours; the veneer is dried by a roller dryer. Carry out drying, the drying temperature is 60°C, the drying time is 30 minutes, and the moisture content is reduced ...

Embodiment 2

[0034] (1) Using sliced poplar veneer as raw material, it is dyed with hindered amine light stabilizer UV-765 and disazoic acid dye C 24 h 22 N 4 o 6 S 2 According to the ratio of 20:200 mass parts to prepare acidic binary compound dyes, dissolve the dyes at 68 ° C, and at the same time turn on the air pump, let air into the dye solution, stir the dye solution to make the concentration uniform, dissolve the dye for 50 minutes, and poplar The veneer is vertically immersed in the dyeing solution, the bath ratio V solution: V plate = 10:1, the temperature is raised at a rate of 2°C / min, and the heat preservation dyeing is carried out at 92°C, and the poplar veneer is dipped for 8 hours; the roller dryer is used for drying The veneer is dried at a drying temperature of 80°C and a drying time of 35 minutes to reduce the moisture content to 8%, and the A veneer is obtained;

[0035] (2) Premix the hindered amine light stabilizer UV-765, antibacterial nano-silver, and tourmalin...

Embodiment 3

[0039] (1) Using the sawn eucalyptus veneer as raw material, it is dyed, and the hindered amine light stabilizer UV-770 and disazoic acid dye C 24 h 22 N 4 o 6 S 2 According to the ratio of 30:300 parts by mass to make acidic binary compound dye, dissolve the dye at 70°C, turn on the air pump at the same time, let air into the dye solution, stir the dye solution to make the concentration uniform, and dissolve the dye for 60 minutes, press the wood The veneer is vertically immersed in the dyeing solution, bath ratio V solution: V plate = 15:1, the temperature is raised at a rate of 3°C / min, and the heat preservation dyeing is carried out at 95°C, and the eucalyptus veneer is dipped for 12 hours; The veneer is dried at a drying temperature of 100°C and a drying time of 45 minutes to reduce the moisture content to 10% to obtain the A veneer;

[0040] (2) Premix the hindered amine light stabilizer UV-770, antibacterial nano-titanium dioxide, and tourmaline powder at a mass rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com