A strain of Staphylococcus saprophyticus and its application in the preparation of dry fermented sausages

A saprophytic staphylococcus, dry fermentation technology, applied in the field of food processing, can solve the problems of long production cycle, seasonal influence, unstable batch quality, etc., and achieve the effect of reducing water activity, attractive taste, and improving overall acceptance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

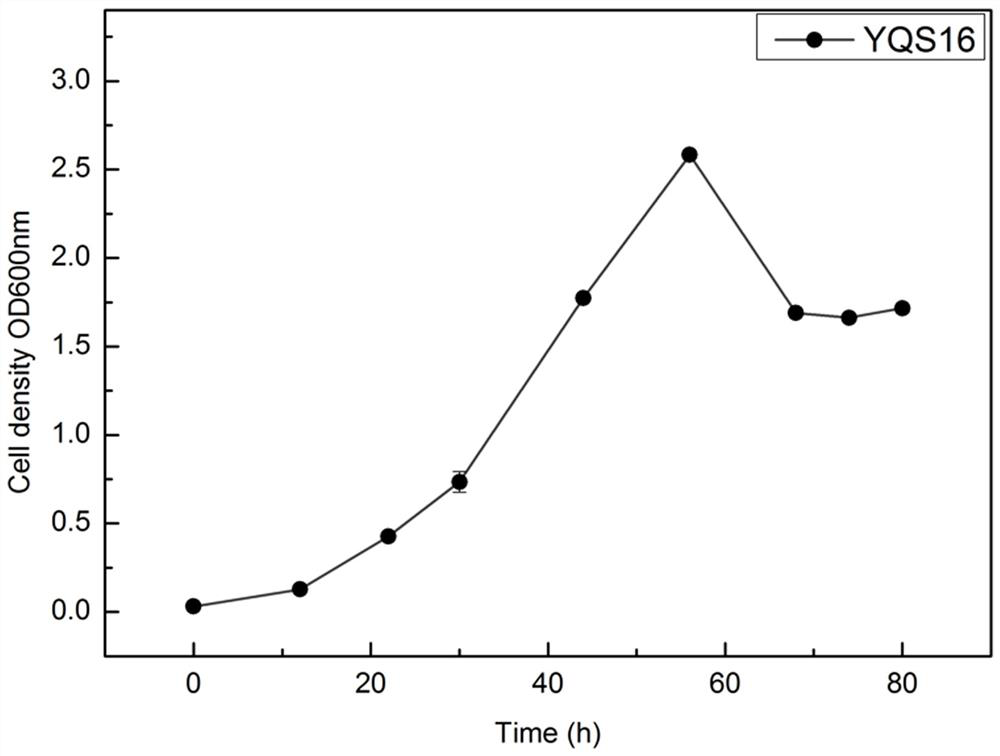

[0034] Screening, identification, production characteristics and safety of Staphylococcus saprophyticus YQS16

[0035] Step a. Staphylococcus enrichment culture: Take 25g of Xuanwei ham sample and transfer it to a 225mL conical flask containing 0.85% saline and glass beads, shake the conical flask on a vortex shaker for 3 minutes, and then dilute the gradient after shaking. , choose 10 3 , 10 4 , 10 5 Three dilution gradients were spread on MSA plate selection medium respectively, and strains with Staphylococcus morphology were selected after culturing at 30°C for 24 hours;

[0036] Step b. Separation and purification of staphylococcus: streak separation on the staphylococcus separation medium MSA, cultivate at 30° C. for 24 hours, repeat the streak separation twice, and inoculate the pure bacteria in the liquid medium.

[0037] Step c. Physiological and biochemical identification of Staphylococcus and 16SrDNA identification: through casein hydrolysis experiment, viscosity ...

Embodiment 2

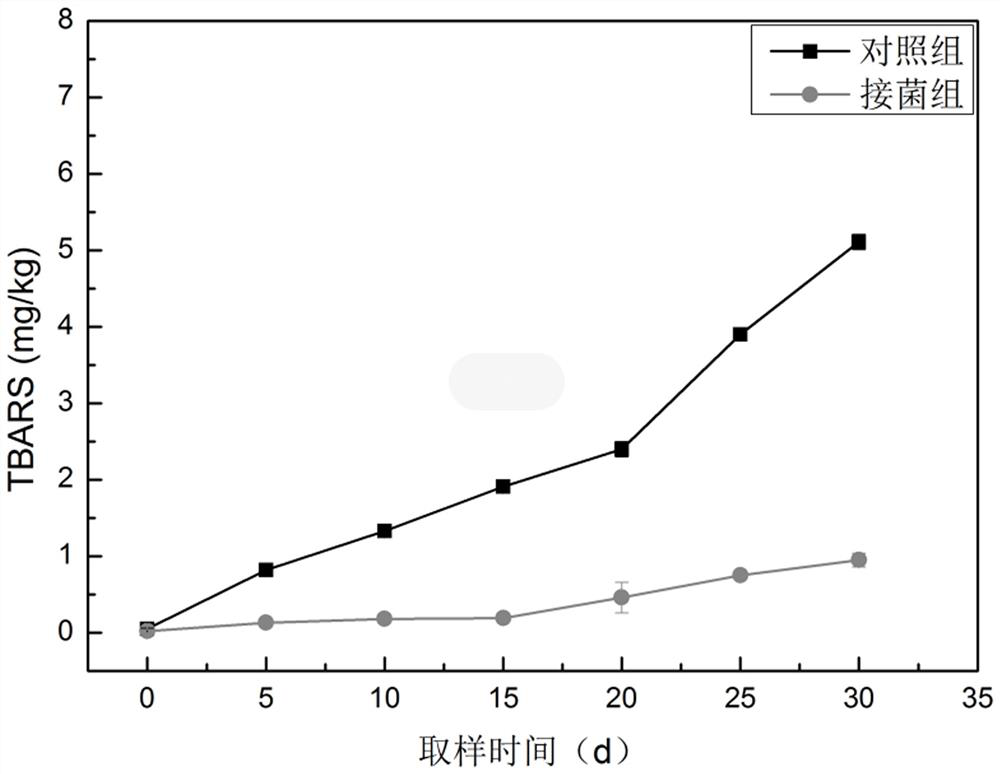

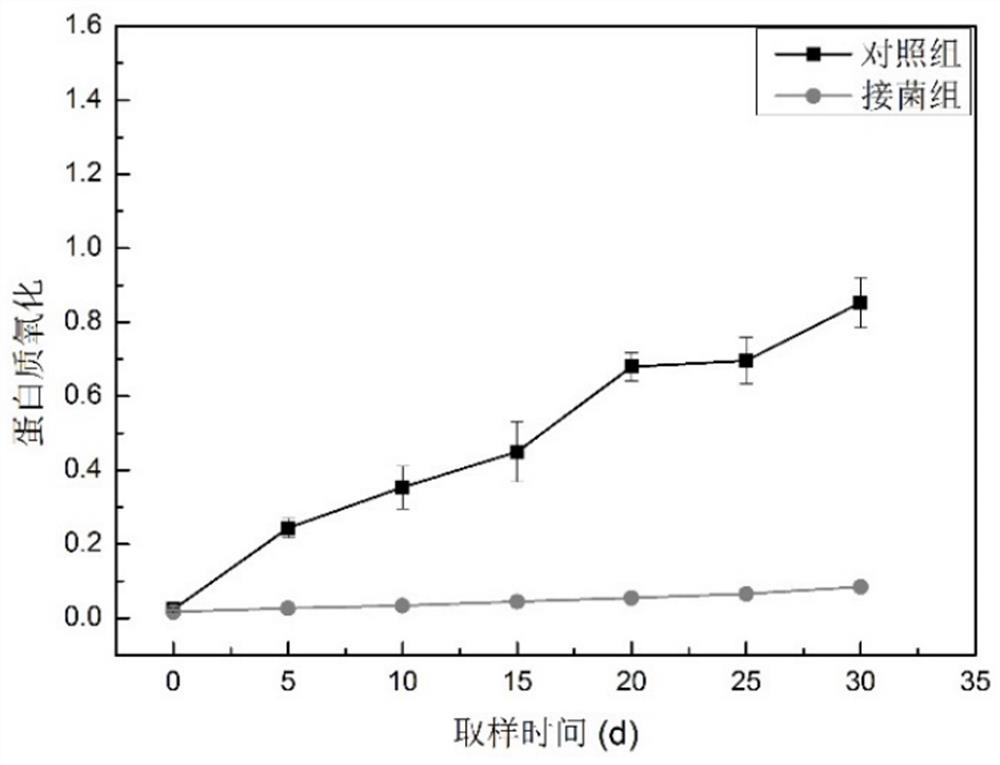

[0075] Application of Staphylococcus saprophyticus in fermented sausage

[0076] It mainly includes the following steps:

[0077] Step a. Preparation of dry powder of Staphylococcus saprophyticus starter: use case peptone yeast extract powder agar medium (PYA) to make Staphylococcus saprophyticus (the number of viable cells more than 10 9 After activation of cfu / g), the shake flask was expanded and cultured, and the number of revolutions was 10,000 r / min, and centrifugation was performed for 10 min; then the bacterial cells were collected to prepare a concentrated bacterial suspension. Add protective agent (skim milk 10.0%, mannitol 5.0%, lactose 5.2%, glycerol 2.5%), vacuum freeze-dry overnight, make starter dry powder, and the viable count reaches 10 6 -10 7 cfu / g;

[0078] Step b. Pre-treatment of raw meat: select the front elbow of the pig (lean meat 75%, fat meat 25%), wash with cold water, remove oil slick and dirt, and drain the water. Divide the processed meat into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com