Antistatic adhesive and preparation method thereof

An antistatic and antistatic agent technology, applied in the direction of adhesives, conductive adhesives, adhesive types, etc., can solve the problems of easily damaged circuit boards, short circuits, protective film peeling, etc., and achieve excellent water repellency and chemical stability Good performance, the effect of eliminating static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The raw materials for the preparation of an antistatic glue include extra-high hexene content raw rubber, raw rubber, silicone oil, hydrogen-containing silicone oil, mold release agent, blue pigment, conductive carbon black and antistatic agent.

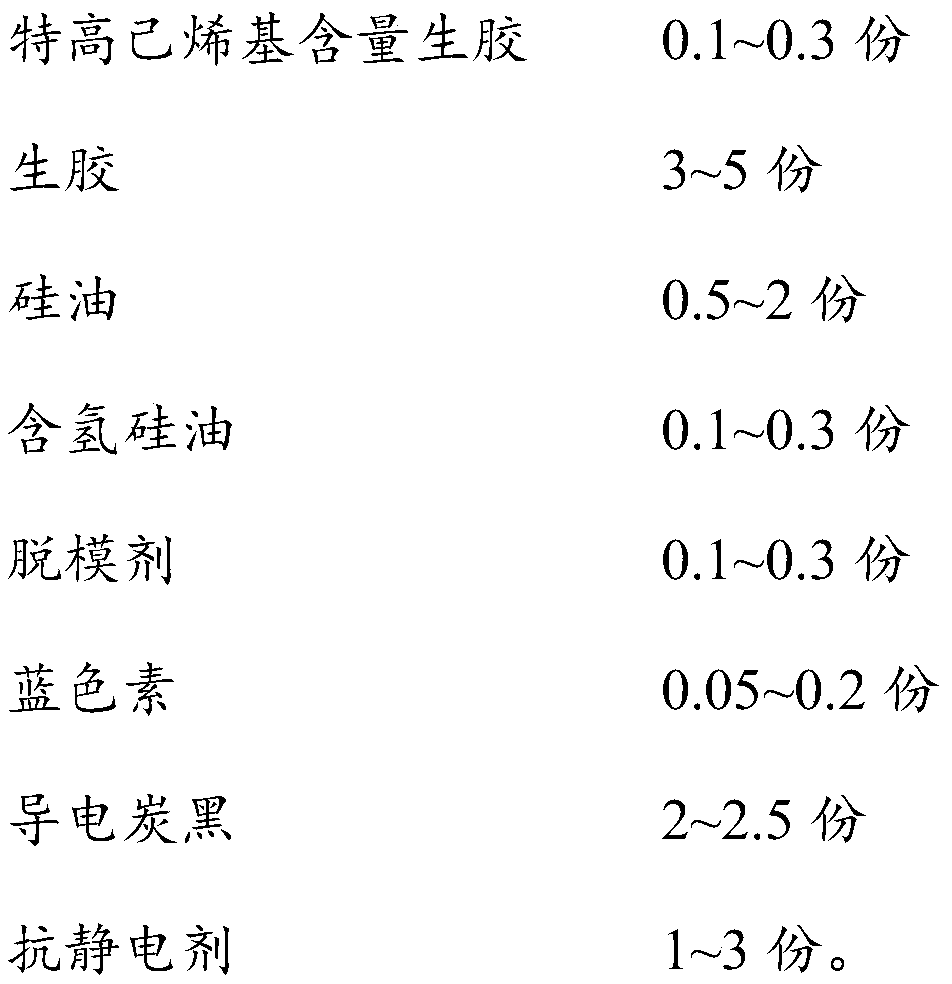

[0024] Wherein, the antistatic adhesive of the present invention includes the following components in parts by weight:

[0025]

[0026] Among them, the relative molecular weight of the ultra-high hexenyl content raw rubber is 55×10 4 , the vinyl content of the ultra-high hexenyl content raw rubber is 3wt%.

[0027] Wherein, the viscosity of silicone oil is 1000cP.

[0028] Wherein, the hydrogen content of the hydrogen-containing silicone oil is 1.6 wt%.

[0029] Wherein, the raw rubber is selected from nitrile rubber.

[0030] Wherein, the release agent is selected from fluororesins.

[0031] Wherein, the particle diameter of conductive carbon black is 8 μm, and the carbon black particle adhesion amount of described co...

Embodiment 2

[0038] The raw materials for the preparation of an antistatic glue include extra-high hexene content raw rubber, raw rubber, silicone oil, hydrogen-containing silicone oil, mold release agent, blue pigment, conductive carbon black and antistatic agent.

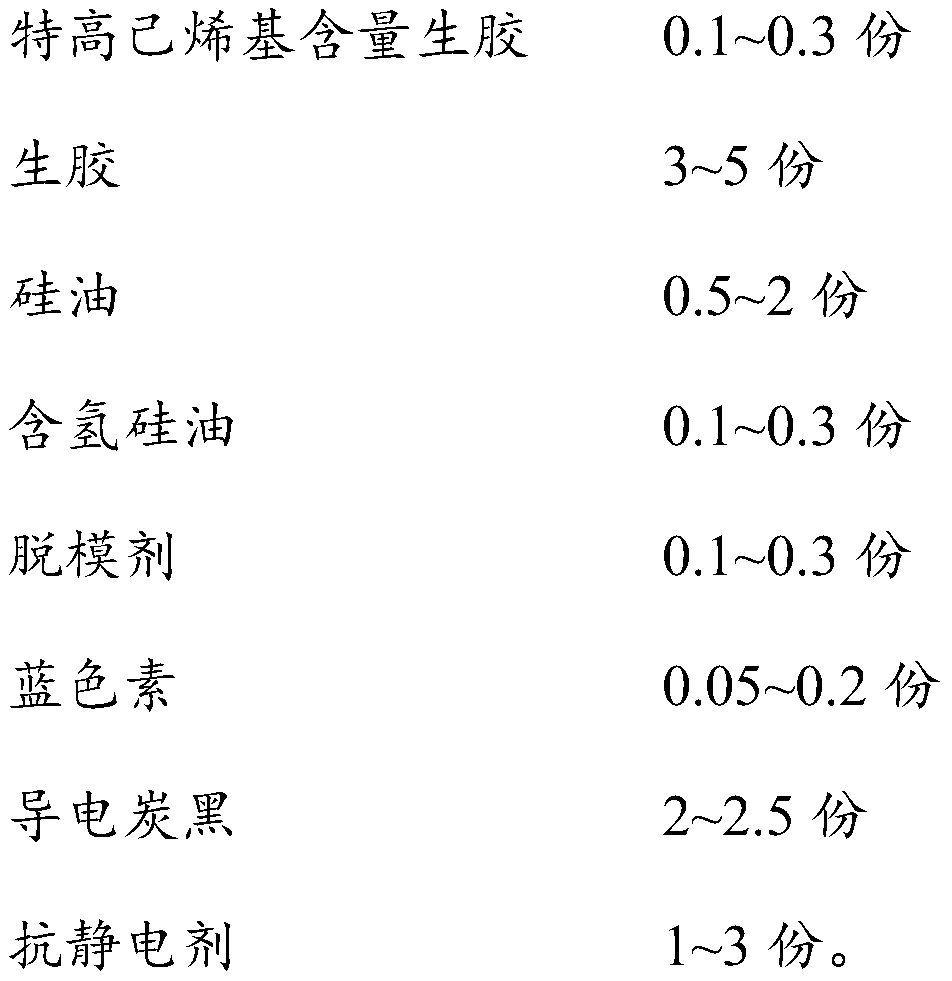

[0039] Wherein, the antistatic adhesive of the present invention includes the following components in parts by weight:

[0040]

[0041]

[0042] Among them, the relative molecular weight of the ultra-high hexenyl content raw rubber is 50×10 4 , the vinyl content of the ultra-high hexenyl content raw rubber is 2.5wt%.

[0043] Wherein, the viscosity of silicone oil is 500cP.

[0044] Wherein, the hydrogen content of hydrogen-containing silicone oil is 1.59wt%.

[0045] Wherein, raw rubber is selected from neoprene.

[0046] Wherein, the release agent is selected from polytetrafluoroethylene.

[0047] Wherein, the particle diameter of conductive carbon black is 2 μm, and the carbon black particle adhesion amount of de...

Embodiment 3

[0054] The raw materials for the preparation of an antistatic glue include extra-high hexene content raw rubber, raw rubber, silicone oil, hydrogen-containing silicone oil, mold release agent, blue pigment, conductive carbon black and antistatic agent.

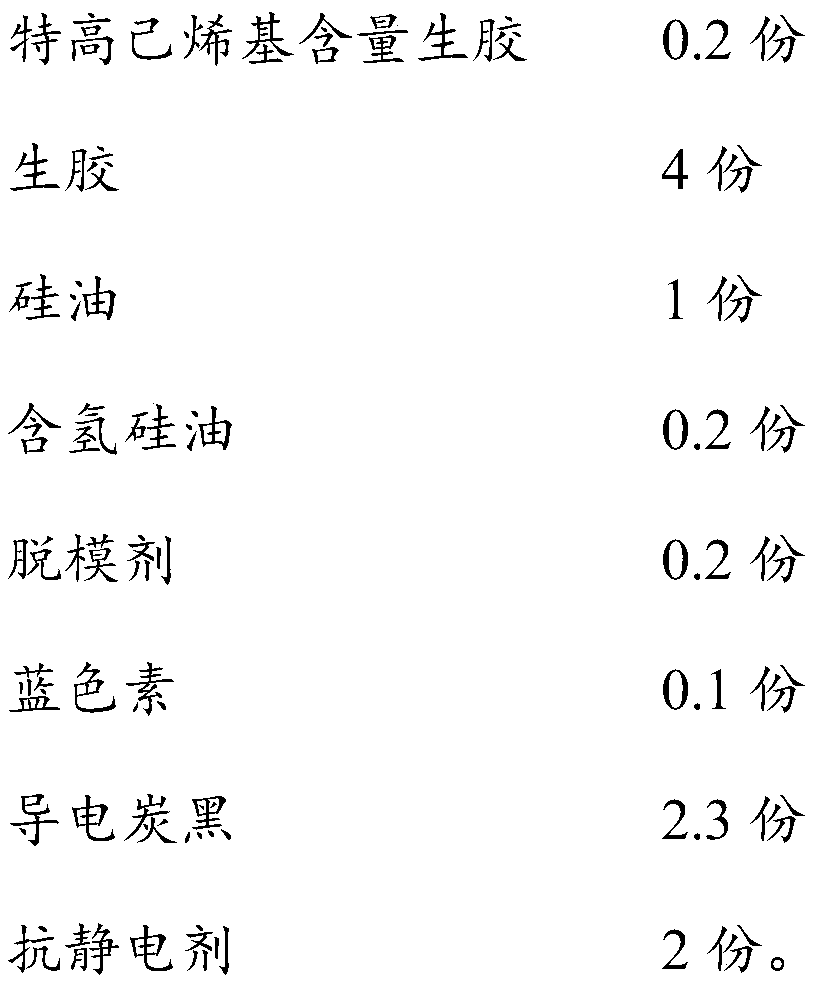

[0055] Wherein, the antistatic adhesive of the present invention includes the following components in parts by weight:

[0056]

[0057] Among them, the relative molecular weight of the ultra-high hexenyl content raw rubber is 50×10 4 , the vinyl content of the ultra-high hexenyl content raw rubber is 3.5wt%.

[0058] Wherein, the viscosity of silicone oil is 1500cP.

[0059] Wherein, the hydrogen content of the hydrogen-containing silicone oil is 1.63wt%.

[0060] Wherein, raw rubber is selected from butyl rubber.

[0061] Wherein, the release agent is selected from silicone rubber.

[0062] Wherein, the particle diameter of conductive carbon black is 2 μm, and the carbon black particle adhesion amount of described con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com