Water-based transparent antistatic coating and preparation method thereof

An antistatic and transparent technology, applied in the direction of conductive coatings, polyester coatings, polyurea/polyurethane coatings, etc., to achieve improved dispersion, facilitate subsequent dispersion, and excellent hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

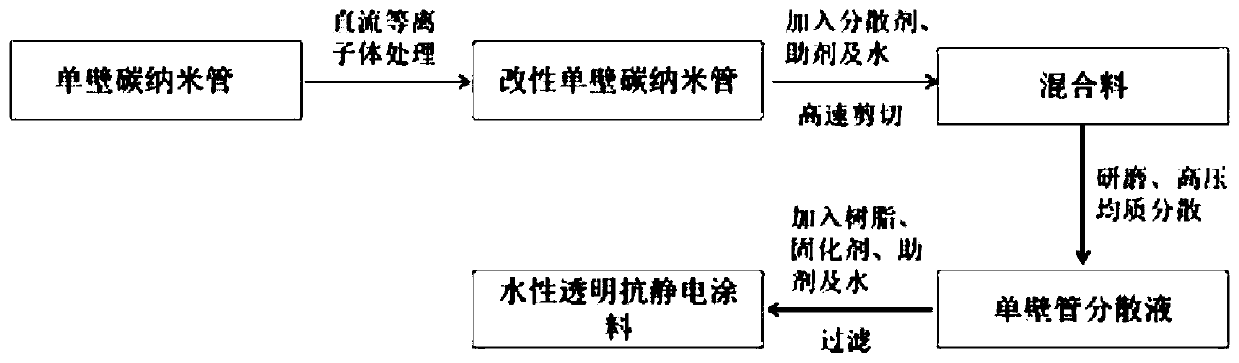

[0034] Another object of the present invention is to provide a kind of preparation method of above-mentioned waterborne transparent antistatic coating, and this method specifically comprises the following steps:

[0035] S1) First, the single-walled carbon nanotubes are treated with DC discharge plasma to improve their hydrophilic properties, and obtain modified single-walled carbon nanotubes;

[0036] S2) Mixing the modified single-walled carbon nanotubes, dispersant, co-dispersant, wetting agent and water, high-speed shear pre-dispersion, and standing for infiltration for 2-24 hours to obtain a mixture;

[0037] S3) Disperse the mixture through sand milling and high-pressure homogeneous grinding in sequence, and grind to a fineness of less than 10 μm to obtain a single-walled carbon nanotube dispersion;

[0038] S4) Add water-based polyurethane resin, water-based polyester resin, water-based curing agent, leveling agent and substrate wetting agent in sequence to S3) to prepare...

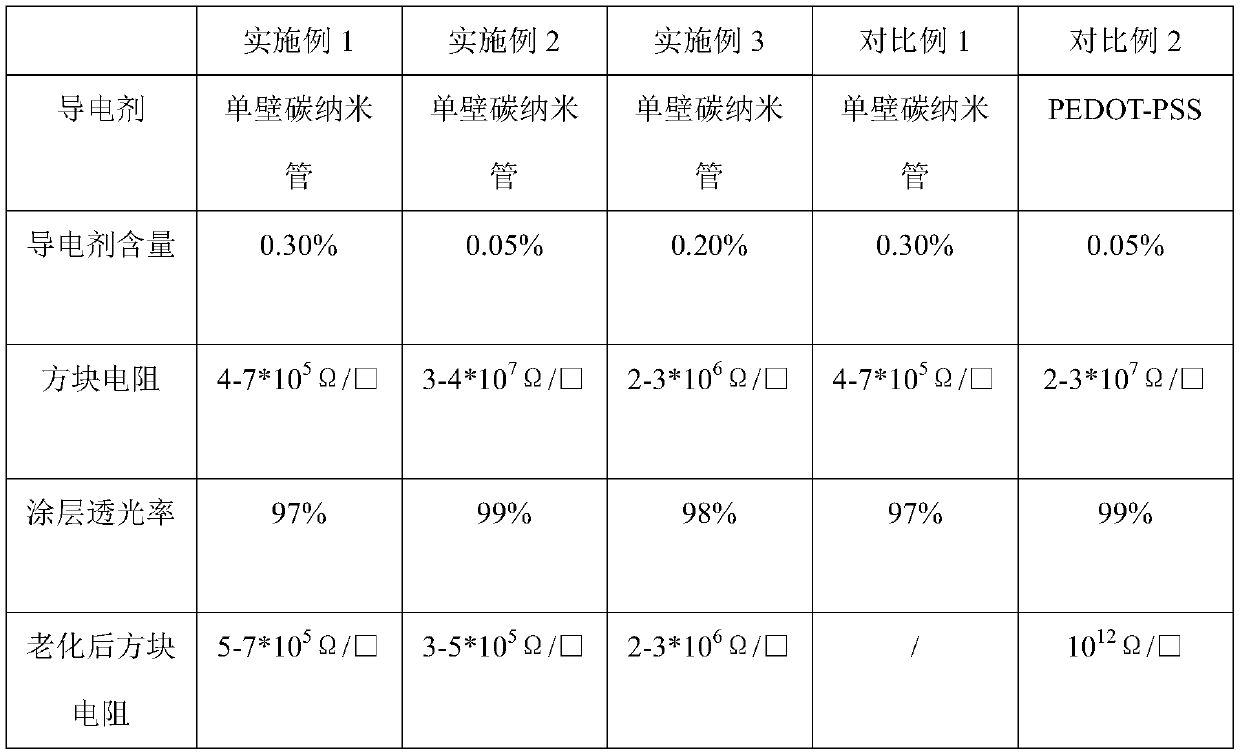

Embodiment 1

[0043] Waterborne transparent antistatic coating, its basic composition and weight percentage are:

[0044] Polycarbonate-based water-based polyurethane resin: 5%, water-based polyester resin: 6%, blocked water-based isocyanate: 0.6%, sodium dodecylbenzenesulfonate: 0.6%; polyvinylpyrrolidone: 0.6%, single-walled carbon nano Tube (diameter 1-2nm): 0.3%, BYK191: 0.3%, BYK333: 0.4%, BYK345: 0.4%, the balance is deionized water

[0045] The preparation steps are as follows: the single-walled carbon nanotubes (chemical vapor deposition method) are loaded into a rotary tube plasma furnace, treated with DC discharge plasma to improve their hydrophilic properties, and obtain modified single-walled carbon nanotubes; then Mix modified single-walled carbon nanotubes, sodium dodecylbenzenesulfonate, polyvinylpyrrolidone, BYK191 and water, and use a high-speed disperser for high-speed shear pre-dispersion, with a shear line speed of 10 m / s and a processing time of After 30 minutes, stand...

Embodiment 2

[0047] Waterborne transparent antistatic coating, its basic composition and weight percentage are:

[0048] Polycarbonate type water-based polyurethane resin: 3%, water-based polyester resin: 2%, melamine formaldehyde resin: 0.1%, alkyl polyoxyethylene ether (OP-10): 0.1%, polyvinyl alcohol 2000: 0.1% single wall Carbon nanotubes (tube diameter 1-2nm): 0.05%, BYK180: 0.1%, BYK378: 0.1%, BYK346; 0.1%, the balance deionized water

[0049] The preparation steps are as follows: the single-walled carbon nanotubes (chemical vapor deposition method) are loaded into a rotary tube plasma furnace, treated with DC discharge plasma to improve their hydrophilic properties, and obtain modified single-walled carbon nanotubes; then Mix modified single-walled carbon nanotubes, alkyl polyoxyethylene ether (OP-10), polyvinyl alcohol 2000, BYK180 and water, and use a colloid mill for high-speed shear pre-dispersion, with a shear line speed of 5 m / s. The treatment time is 2 hours, and the mixed m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com