Antistatic PET engineering plastic and preparation method thereof

An engineering plastic and antistatic technology, applied in the field of polymer composite materials and their preparation, to achieve the effects of reducing usage, improving mechanical properties, improving dispersibility and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

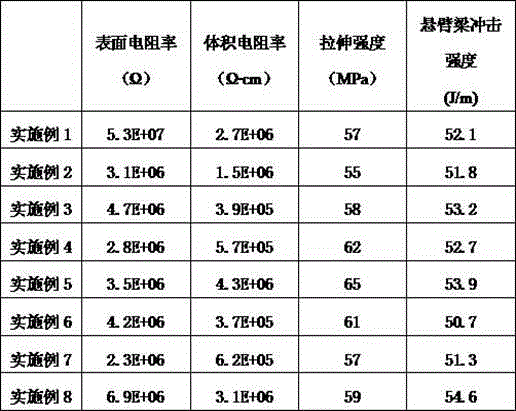

Examples

Embodiment 1

[0032] A kind of antistatic PET engineering plastics, its preparation method is by steps:

[0033] Step 1. Put 3 parts of carbon nanotube A and 2 parts of carbon nanotube B into concentrated H with a volume ratio of 3:1. 2 SO 4 and HNO 3 In the mixed solution, under the action of ultrasonic vibration and mechanical stirring, it was treated for 4 hours, and then washed with a large amount of deionized water until neutral;

[0034] Step 2. Put the obtained carbon nanotubes into an ethanol solution containing 0.5% titanate coupling agent by mass percentage, oscillate with ultrasonic waves (at a temperature of 80° C.) for 2 hours, filter, and dry in vacuum;

[0035] Step 3, drying 95 parts of PET polyester chips in an oven at 140°C for 4 hours;

[0036] Step 4, 95 parts of PET polyester chips after drying and 3 parts of carbon nanotube A and 2 parts of carbon nanotube B after vacuum drying, and 0.2 part of polyethylene wax, 0.05 part of tetrakis [β-(3,5-di tert-butyl-4-hydroxy...

Embodiment 2

[0038] A kind of antistatic PET engineering plastics, its preparation method is by steps:

[0039] Step 1. Put 5 parts of carbon nanotubes A and 2 parts of carbon nanotubes B into concentrated H with a volume ratio of 3:1. 2 SO 4 and HNO 3 In the mixed solution, under the action of ultrasonic vibration and mechanical stirring, treat for 3h, then wash with a large amount of deionized water until neutral;

[0040] Step 2. Put the obtained carbon nanotubes into an ethanol solution containing 0.3% titanate coupling agent by mass percentage, oscillate with ultrasonic waves (at a temperature of 80° C.) for 3 hours, filter, and dry in vacuum;

[0041] Step 3, drying 90 parts of PET polyester chips in an oven at 150°C for 5 hours;

[0042] Step 4, 90 parts of PET polyester chips after drying and 5 parts of carbon nanotubes A and 2 parts of carbon nanotubes B after vacuum drying, and 0.3 parts of polyethylene wax, 0.04 parts of four [β-(3,5-di tert-butyl-4-hydroxyphenyl)propionic a...

Embodiment 3

[0044] A kind of antistatic PET engineering plastics, its preparation method is by steps:

[0045] Step 1. Put 6 parts of carbon nanotube A and 1 part of carbon nanotube B into concentrated H 2 SO 4 and HNO 3 In the mixed solution (volume ratio 3:1), under the action of ultrasonic vibration and mechanical stirring, treat for 5h, then wash with a large amount of deionized water until neutral;

[0046] Step 2. Put the obtained carbon nanotubes into an ethanol solution containing 0.6% titanate coupling agent by mass percentage, vibrate with ultrasonic waves (at a temperature of 80° C.) for 4 hours, filter, and dry in vacuum;

[0047]Step 3, drying 92 parts of PET polyester chips in an oven at 140°C for 4 hours;

[0048] Step 4, 92 parts of dried PET polyester chips and 6 parts of carbon nanotube A and 1 part of carbon nanotube B after vacuum drying, and 0.8 part of polyethylene wax, 0.06 part of tetra[β-(3,5- Di-tert-butyl-4-hydroxyphenyl) propionate] Pentaerythritol was mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com