Preparation method for washable and antibacterial down feathers

A washable and down-resistant technology, applied in the field of down, can solve the problems of poor fluffy performance of down, loss of antibacterial function, damage to down performance, etc., and achieve good antibacterial function, no reduction in antibacterial performance, and less damage to down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

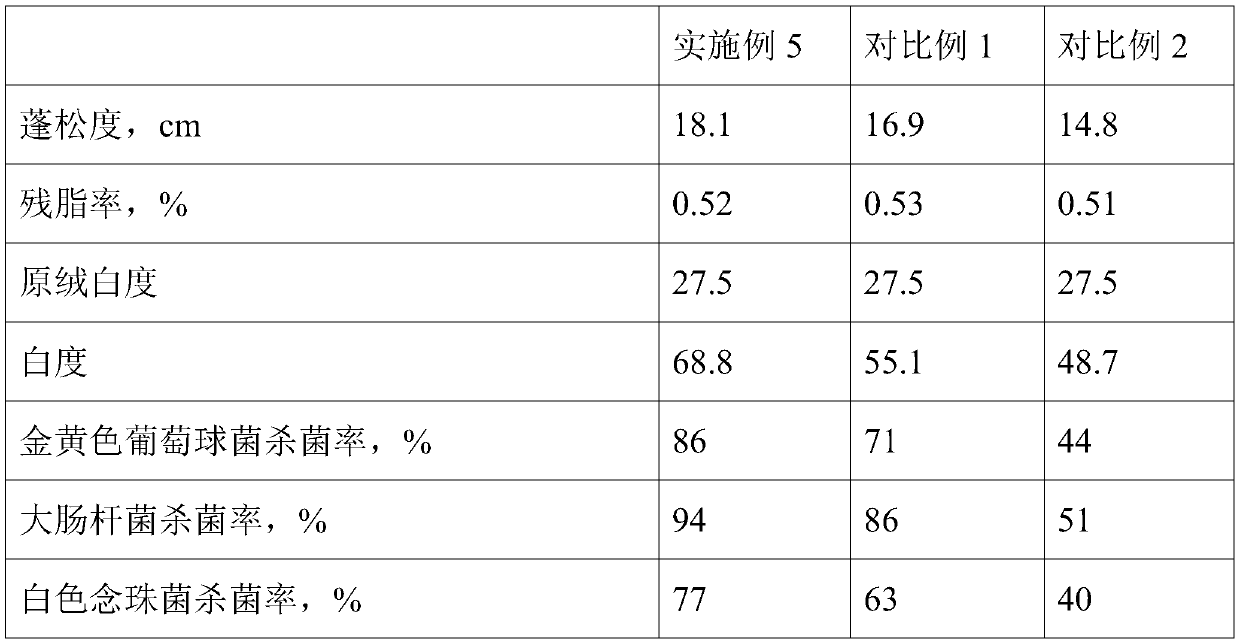

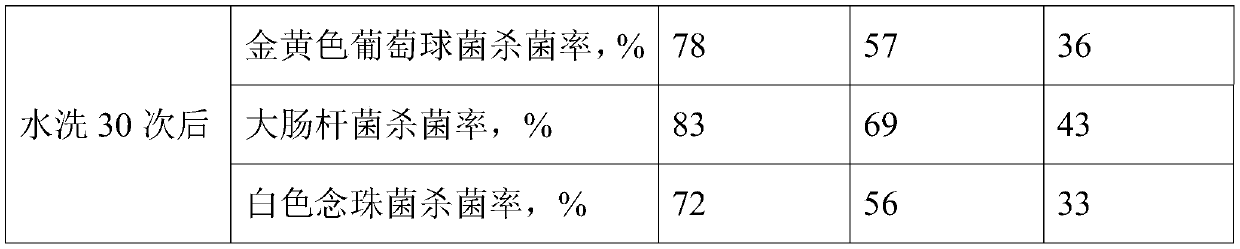

Examples

Embodiment 1

[0021] A method for preparing water-resistant and antibacterial down, comprising the steps of:

[0022] S1. Wash the raw down for 25 minutes, dehydrate it, and dry it at 65°C to remove residual dust and sand to obtain pretreated down;

[0023] S2, adding 1kg of detergent to 70kg of pretreated down and down for fine washing for 15 minutes, then rinsing with clear water for 6 times, dehydrating to a water content of 15wt%, adding 12kg of humic acid complex, 2kg of chitosan with a deacetylation degree of 83% Mix evenly, soak for 15 minutes, filter, wash, dry at 70°C, and cool to obtain washable and antibacterial down.

[0024] The washing liquid comprises by weight percentage: 1.5% of compound enzyme, 22% of surface active agent, 4% of softening agent, and the balance is water.

[0025] The humic acid complex is prepared by the following process: mix 25kg of humic acid and 60kg of 0.8mol / L sodium hydroxide solution, heat up to 75°C and stir for 30min, add 0.2kg of disproportiona...

Embodiment 2

[0027] A method for preparing water-resistant and antibacterial down, comprising the steps of:

[0028] S1. Wash the raw down for 35 minutes, dehydrate it, and dry it at 55°C to remove residual dust and sand to obtain pretreated down;

[0029] S2, adding 2kg of detergent to 50kg of pretreated eider down and carrying out fine washing for 25min, then rinsing with clear water twice, dehydrating to a water content of 20wt%, adding 4kg of humic acid complex, 6kg of chitosan with a deacetylation degree of 81% Mix evenly, soak for 25 minutes, filter, wash, dry at 50°C, and cool to obtain washable and antibacterial down.

[0030] The washing liquid comprises by weight percentage: 2.5% of compound enzyme, 16% of surface active agent, 8% of softening agent, and the balance is water.

[0031] The humic acid complex is prepared by the following process: mix 15kg of humic acid and 100kg of 0.4mol / L sodium hydroxide solution, heat up to 85°C and stir for 20min, add 0.4kg of disproportionat...

Embodiment 3

[0033] A method for preparing water-resistant and antibacterial down, comprising the steps of:

[0034] S1. Wash the raw down for 28 minutes, dehydrate, and dry at 62°C to remove residual dust and sand to obtain pretreated down;

[0035] S2. Add 1.2kg of detergent to 65kg of pretreated down for fine washing for 18 minutes, then rinse with water for 5 times, dehydrate until the water content is 16wt%, add 10kg of humic acid complex, 3kg of chitosan with a deacetylation degree of 82.5% The sugar is mixed evenly, soaked for 18 minutes, filtered, washed, dried at 65°C, and cooled to obtain washable and antibacterial down.

[0036] The washing liquid comprises by weight percentage: 1.8% of compound enzyme, 20% of surface active agent, 5% of softening agent, and the balance is water.

[0037] The humic acid complex is prepared by the following process: mix 22kg humic acid and 70kg sodium hydroxide solution with a concentration of 0.7mol / L, heat up to 78°C and stir for 28min, add 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com