Palladium-carbon filtering and recycling system and method

A recovery system and palladium-carbon technology, applied in the field of cyclohexanecarboxylic acid production, can solve the problems of easily causing accidents, low efficiency, complex recovery processes, etc., and achieve the effects of reducing the risk of safety accidents, reducing losses, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

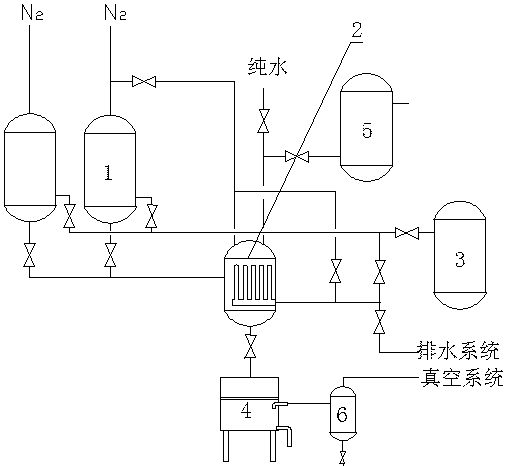

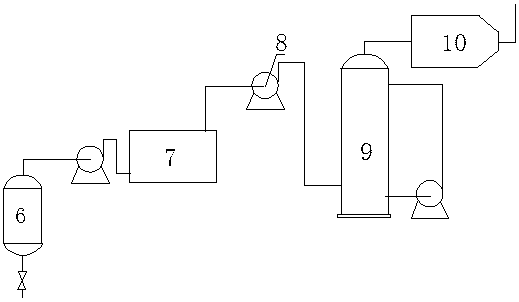

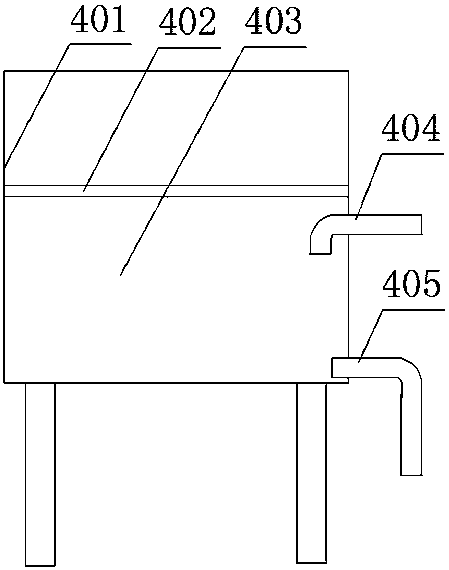

[0023] like figure 1 The shown palladium-carbon filtration recovery system comprises a hydrogenation reactor 1, a filter 2 connected to the bottom of the hydrogenation reactor 1 through pipelines and valves, and nitrogen gas connected to the filtrate outlet of the filter 2 through pipelines and valves Back blowing mechanism, drainage system and cyclohexyl formic acid crude product tank 3, palladium carbon suction filter 4 connected to the filter residue outlet of filter 2 through pipes and valves, pure water pipe communicated with the liquid inlet chamber of filter 2 through pipes and valves And exhaust buffer tank 5. Filter 2 adopts titanium metal powder sintered filter element. like image 3 and Figure 4 As shown, the palladium-carbon suction filter 4 includes a body 401, which is connected with the body 401 and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com