Preparation method of efficient Co/CNTs catalyst for Fischer-Tropsch synthesis reaction

A catalyst and Tropor synthesis technology, which is applied in the field of preparation of high-efficiency Co/CNTs catalysts, can solve the problems of poor catalyst stability, easy sintering, and increased costs, and achieve high reducibility, improved reaction activity, and high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method for an efficient Co / CNTs catalyst for Fischer-Tropsch synthesis reaction, the steps are as follows:

[0034] (1) Pretreatment of carrier CNTs:

[0035] Put 2g of CNTs in a 250mL round-bottomed flask equipped with a reflux trap and a condenser tube, and add 200mL of 65wt.% HNO to it 3 , then heated and refluxed at 80°C for 6h under stirring at 20rpm, after the temperature dropped to room temperature, vacuum filtered, and the obtained solid was repeatedly washed with deionized water until neutral, dried in an oven at 100°C for 12h, and cooled After reaching room temperature, it is ground into powder to obtain the pretreated CNTs carrier;

[0036] (2) Preparation of Co / CNTs by equal volume impregnation method:

[0037] According to the theoretical loading of Co on the carrier CNTs is 15%, weigh 1.74g of cobalt nitrate hexahydrate and dissolve it in 6.3mL of deionized water, then add the aqueous solution of cobalt nitrate dropwise into the equipment p...

Embodiment 2

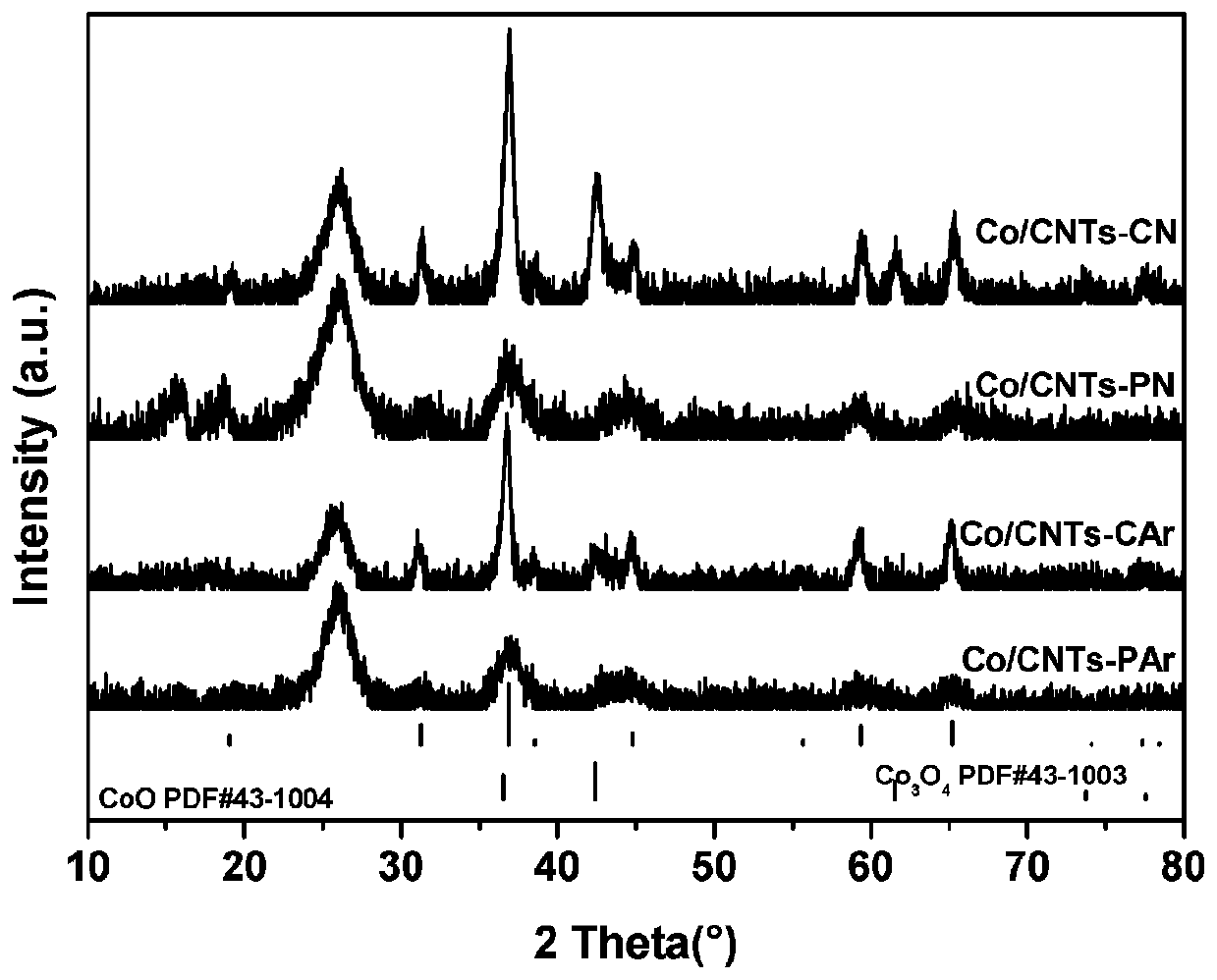

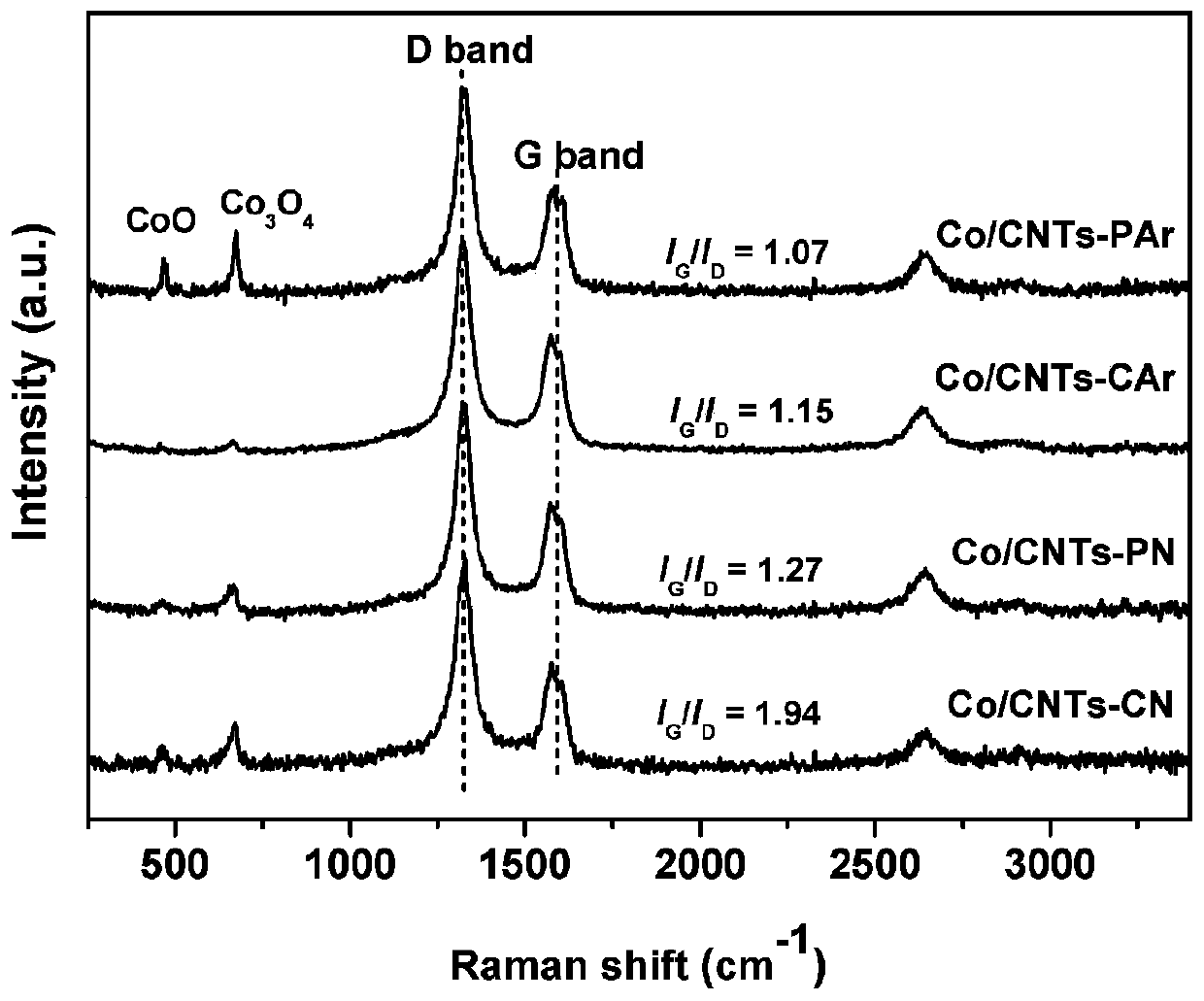

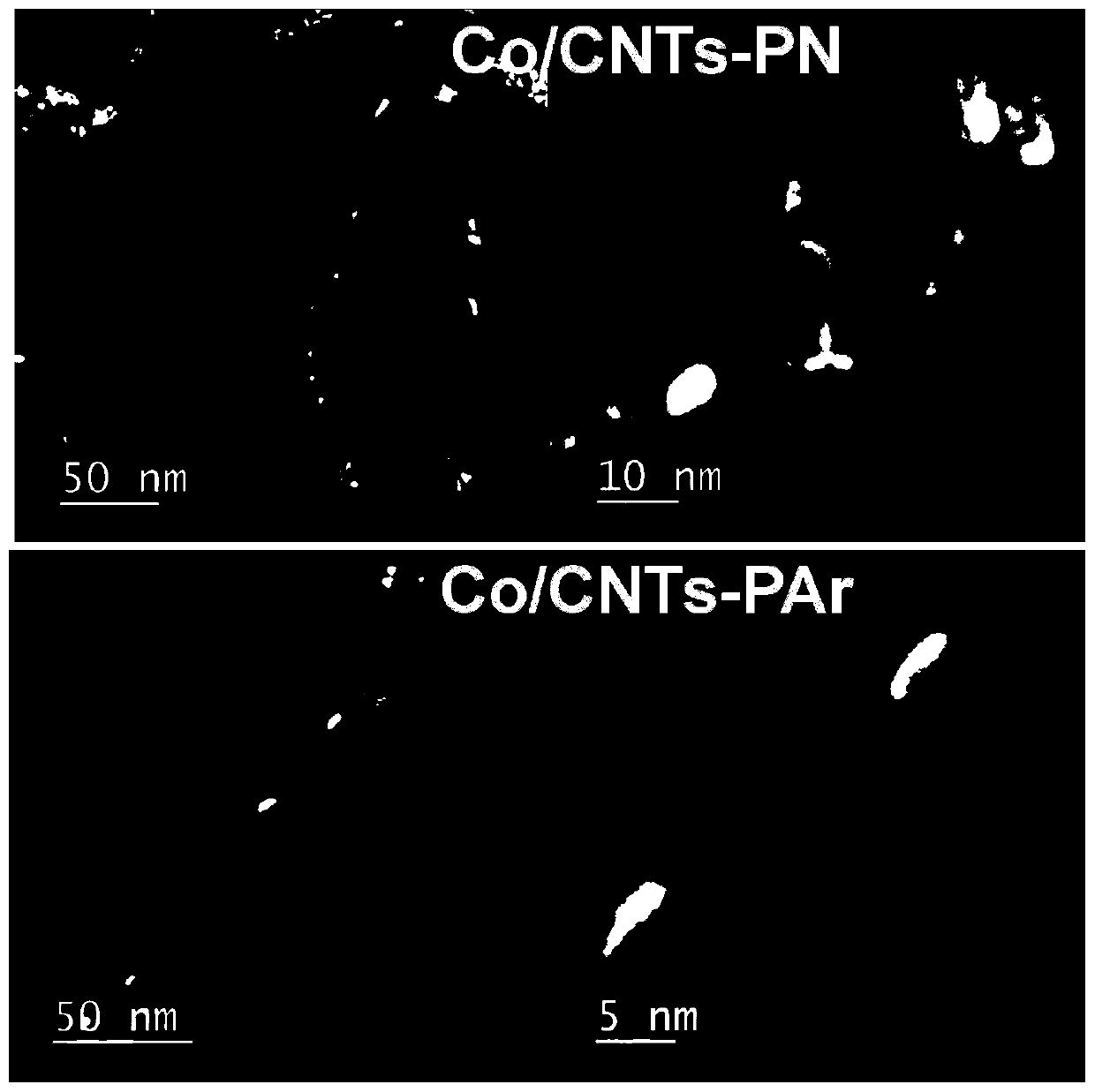

[0046] Different inert atmosphere (N 2 , Ar) Co / CNTs-PN and Co / CNTs-PAr catalysts prepared by plasma and Co / CNTs-CN and Co / CNTs-CAr catalysts prepared by impregnation and direct roasting were applied to catalyze the Fischer-Tropsch synthesis reaction and react Stability testing.

[0047] The experiment was carried out in a fixed-bed reactor, first reduced under pure hydrogen atmosphere, reduction conditions: normal pressure, under hydrogen atmosphere, 4SL·g -1 h -1 , reduced at 400°C for 10h; after cooling down, switch to syngas for reaction, reaction conditions: space velocity 4SL·g -1 h -1 , 1.0MPa, T=200℃, H 2 / CO=2:1 (volume ratio).

[0048] The performance of each catalyst in catalyzing Fischer-Tropsch synthesis is shown in Table 1 and Figure 5 As shown, the reaction data taken in Table 1 is the average activity data of 100 h after reaching the reaction temperature of 200 ° C and stabilizing.

[0049] It can be seen that the Fischer-Tropsch synthesis reaction acti...

Embodiment 3

[0054] A preparation method for an efficient Co / CNTs catalyst for Fischer-Tropsch synthesis reaction, the steps are as follows:

[0055] (1) Pretreatment of carrier CNTs:

[0056] Put 2g of CNTs in a 250mL round-bottomed flask equipped with a reflux trap and a condenser tube, and add 200mL of 65wt.% HNO to it 3 , and then heated and refluxed at 80°C for 6h under stirring at 20rpm. After the end, the temperature dropped to room temperature, vacuum filtered, and the obtained solid was repeatedly washed with deionized water until neutral, then dried in an oven at 100°C for 12h, and cooled to Grinding into powder after room temperature to obtain pretreated CNTs carrier;

[0057] (2) Preparation of Co / CNTs by equal volume impregnation method:

[0058] According to the theoretical loading of Co on the carrier CNTs is 15%, weigh 1.74g of cobalt nitrate hexahydrate and dissolve it in 6.3mL of deionized water, then add the aqueous solution of cobalt nitrate dropwise into the pretreat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com