A preparation method of an integral powder sintered external light filter tube

An integral, powder-based technology, applied in the field of powder metallurgy products, can solve the problems of difficulty in meeting the service life requirements of filter tubes, easy corrosion and cracking of welds, and high bonding strength of filter cakes on the outer surface, achieving significant economic and social benefits. Benefit, low cost, excellent sintering strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

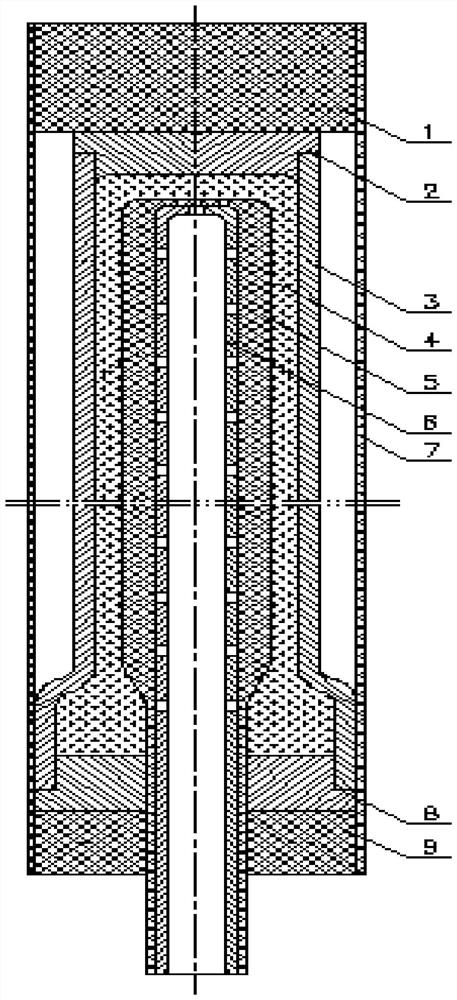

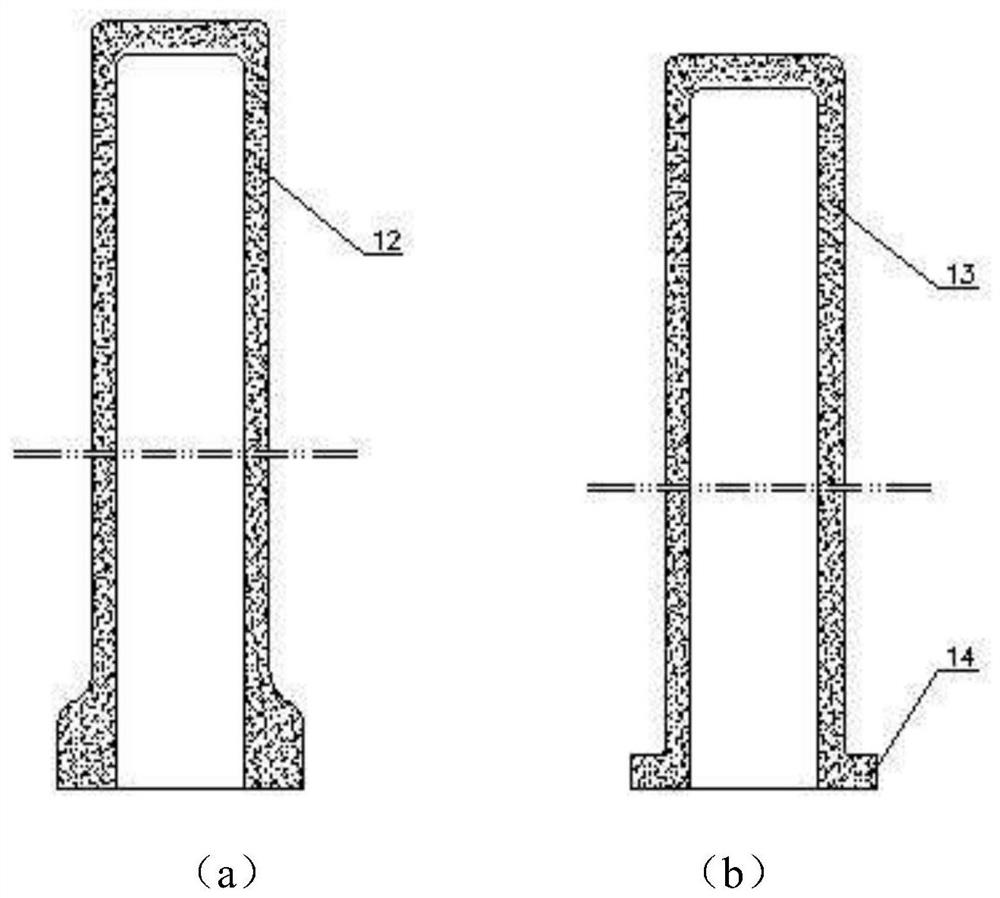

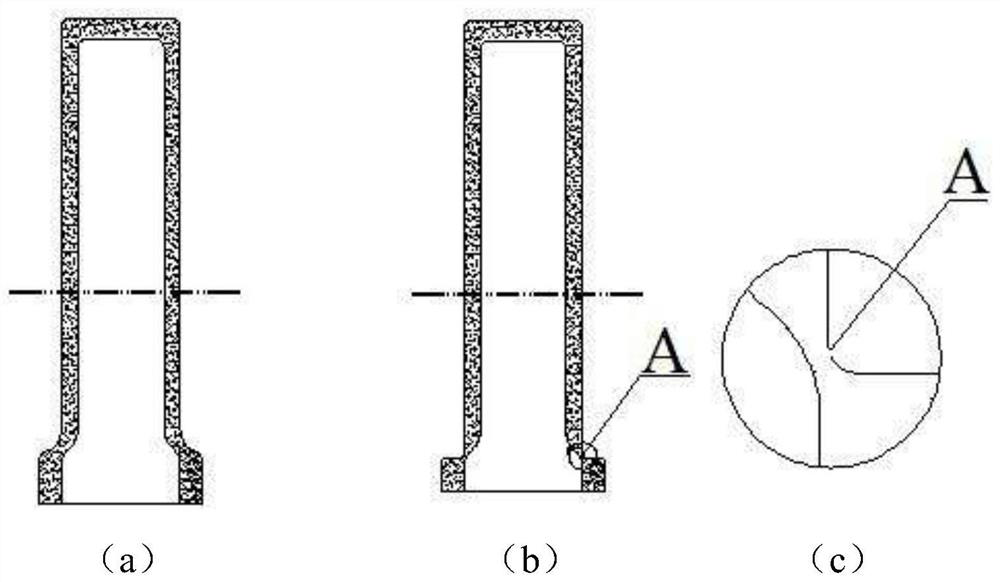

[0059] The preparation of the integral powder sintered external light filter tube adopts a cold isostatic pressing mold; the cold isostatic pressing mold includes a core tube 6 and an outer mold sleeve 3, the outer mold sleeve 3 is set on the outside of the core tube 6, and the outer wall of the core tube 6 is sleeved There is an inner rubber sleeve 5, and the end of the inner rubber sleeve 5 close to the opening of the core tube 6 is sequentially installed with a centering ring 8 and a rubber ring sleeve 9, and the end of the outer mold cover 3 close to the opening of the core tube 6 is fixedly connected with the centering ring 8, and the outer The other end of the mold cover 3 is equipped with a steel plug 2, and the top of the steel plug 2 is equipped with a rubber plug 1, and the outside of the rubber plug 1 and the outer mold cover 3 are equipped with an outer rubber sleeve 7; the steel plug 2, the inner rubber sleeve 5, the outer An n-type cavity is arranged between the d...

Embodiment 2

[0069] The cold isostatic pressing mold that adopts is identical with embodiment 1.

[0070] The preparation method of an integral powder sintered external light filter tube of the present invention is as follows:

[0071] (1) The cold isostatic pressing mold is placed on the vibration table, and the metal powder 4 is filled with the metal powder 4 by the centering ring 8 and is vibrated for later use; wherein, the metal powder 4 is pure nickel; the particle size of the metal powder 4 is 100 / 160 mesh, the volume is 316L;

[0072] (2) Place and fix the cold isostatic pressing mold loaded with metal powder 4 into the working cavity of the cold isostatic pressing machine, press the metal powder 4 and lower it to normal pressure, take out the cold isostatic pressing mold, and remove the rubber Plug 1, steel plug 2, inner rubber sleeve 5, core pipe 6, outer rubber sleeve 7, centering ring 8 and rubber ring sleeve 9, to obtain a powder green body with outer mold sleeve 3; wherein,...

Embodiment 3

[0078] The cold isostatic pressing mold that adopts is identical with embodiment 1.

[0079] (1) The cold isostatic pressing mold is placed on the vibrating table, and the metal powder 4 is filled with the metal powder 4 by using the centering ring 8 and is vibrated for subsequent use; wherein the metal powder 4 is a monel alloy; the particle size of the metal powder 4 is 60 / 100 mesh, take 400L;

[0080] (2) Place and fix the cold isostatic pressing mold loaded with metal powder 4 into the working cavity of the cold isostatic pressing machine, press the metal powder 4 and lower it to normal pressure, take out the cold isostatic pressing mold, and remove the rubber Plug 1, steel plug 2, inner rubber sleeve 5, core pipe 6, outer rubber sleeve 7, centering ring 8 and rubber ring sleeve 9, to obtain a powder green body with outer mold sleeve 3; wherein, the cold isostatic press The pressing pressure is 180MPa, and the holding time is 6min;

[0081] (3) Evenly load white corundum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com