Special magnesia-calcium brick and manufacturing method thereof

A special magnesia-calcium brick and magnesia-calcium brick technology is applied in the field of refractory materials for stainless steel smelting furnaces, which can solve the problems affecting the high-temperature service performance and service life of magnesia-calcium bricks, insufficient erosion resistance and slag resistance, and can not meet the needs of refining customer blast furnaces. Age and other issues, to achieve the effect of improving high temperature performance and corrosion resistance, improving high temperature strength and thermal shock stability, and reducing grain density defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

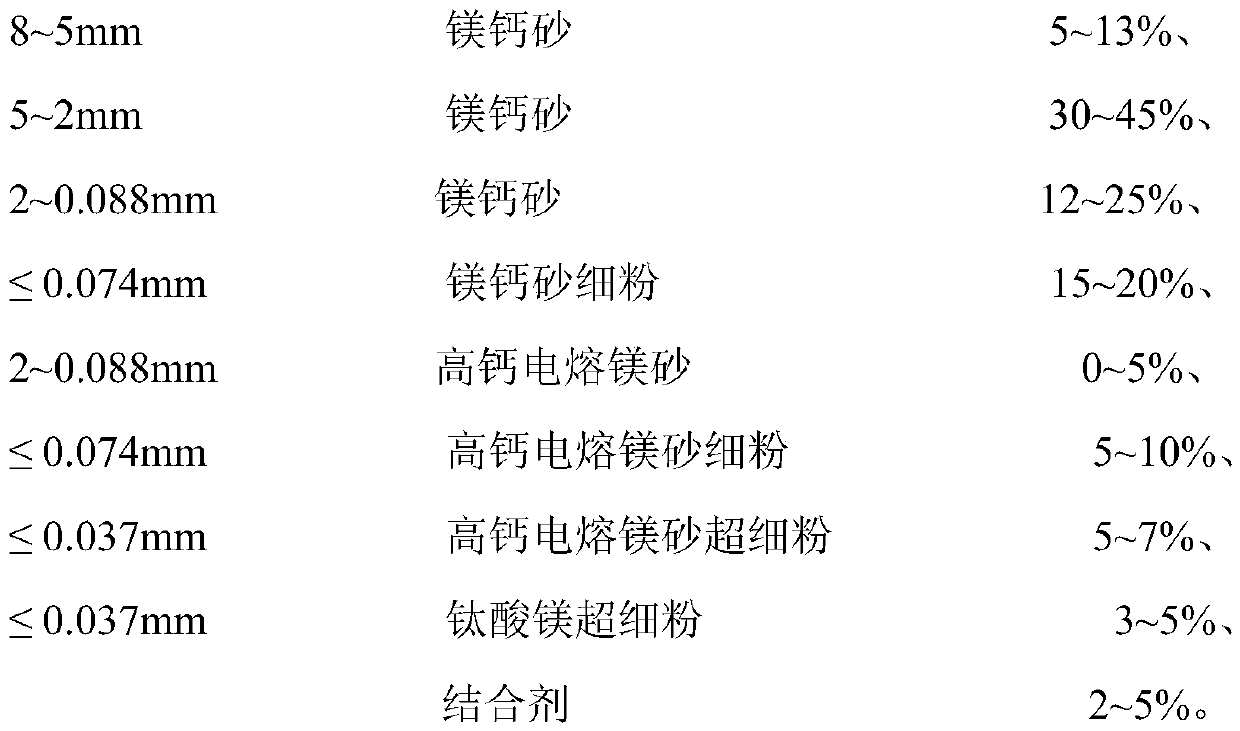

[0082] A special magnesia-calcium brick and a manufacturing method thereof are prepared from the following raw materials in proportions by weight:

[0083]

[0084] The physical and chemical indicators of the high-calcium fused magnesia, magnesia-calcium sand and magnesium titanate are as follows:

[0085] Table 3 Physical and chemical indicators of each raw material

[0086]

[0087]

[0088] The binding agent is paraffin.

[0089] The process for manufacturing the above-mentioned special magnesia-calcium bricks comprises the following steps:

[0090] 1) Raw material crushing: the raw materials of high-calcium fused magnesia-calcium sand and magnesia-calcium sand are successively crushed, screened, and pulverized by a jaw crusher, a double-roller crusher, and a Raymond mill to produce Granular material with a particle size of 8-5mm, 5-2mm, 2-0.088mm and fine powder ≤0.074mm and ≤0.037mm;

[0091] 2) Fine powder premixing: mix high-calcium fused magnesia fine powde...

Embodiment 2

[0099] A special magnesia-calcium brick and a manufacturing method thereof are prepared from the following raw materials in proportions by weight:

[0100]

[0101] The physical and chemical indicators of the high-calcium fused magnesia, magnesia-calcium sand and magnesium titanate are as follows:

[0102] Table 4 Physical and chemical indicators of each raw material

[0103]

[0104]

[0105] The binding agent is paraffin.

[0106] The process for manufacturing the above-mentioned special magnesia-calcium bricks comprises the following steps:

[0107] 1) Raw material crushing: the raw materials of high-calcium fused magnesia-calcium sand and magnesia-calcium sand are successively crushed, screened, and pulverized by a jaw crusher, a double-roller crusher, and a Raymond mill to produce Granular material with a particle size of 8-5mm, 5-2mm, 2-0.088mm and fine powder ≤0.074mm and ≤0.037mm;

[0108] 2) Fine powder premixing: mix high-calcium fused magnesia fine powde...

Embodiment 3

[0116] A special magnesia-calcium brick and a manufacturing method thereof are prepared from the following raw materials in proportions by weight:

[0117]

[0118]

[0119] The physical and chemical indicators of the high-calcium fused magnesia, magnesia-calcium sand and magnesium titanate are as follows:

[0120] Table 5 Physical and chemical indicators of each raw material

[0121] project High calcium fused magnesia Magnesia calcium sand Magnesium titanate MgO,% ≥91.00 ≥61.00 — CaO,% 5-8 ≥30 — ΣSiO 2 +Al 2 o 3 +Fe 2 o 3 ,%

≤1.50 ≤2.00 — Bulk density, g / cm 3

≥3.46 ≥3.23 — MgO / TiO 2 (The molar ratio of)

— — 2.000±0.01 CaO(wt%) — — <0.05

Fe 2 o 3 (wt%)

— — <0.05

K 2 O+Na 2 O (wt%)

— — <0.05

Al 2 o 3 (wt%)

— — <0.1

SiO 2 (wt%)

— — <0.1

[0122] The binding agent is paraffin.

[0123] The above-mentioned manufacturing met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com