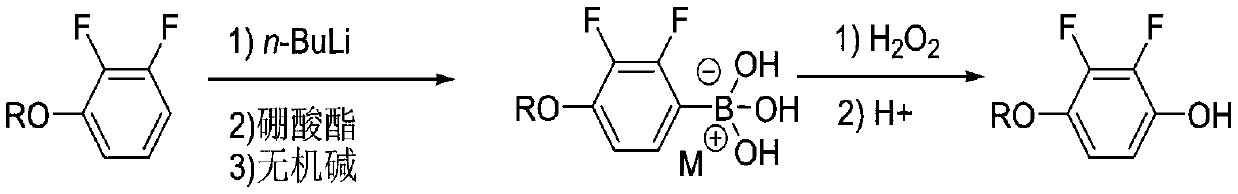

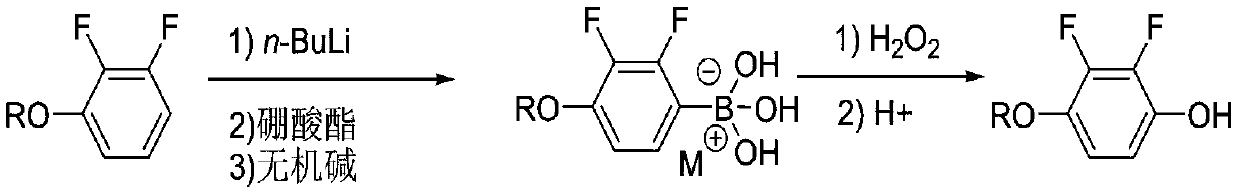

Synthesis process of 2, 3-difluoro-4-alkoxy phenol

A technique for the synthesis of alkoxyphenols, which is applied in the field of synthesis techniques of 2,3-difluoro-4-alkoxyphenols, can solve the problems of difficulty in purifying qualified products, low yields, and poor reaction effects, and achieve The effect of low cost, low equipment requirements and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: 1000mL four-neck bottle, equipped with a thermometer and a condenser tube, under nitrogen protection, put 57.6g (0.4mol) of 2,3-difluoroanisole and 440mL of tetrahydrofuran, start stirring, and cool down to -85°C in a low-temperature bath At ~-75°C, 192 mL (0.48 mol) of n-butyl lithium in n-hexane solution (2.5 mol / L) was slowly added dropwise. After the addition was complete, the mixture was stirred at controlled temperature for 2.0 hours. After the heat preservation is completed, 62.3 g (0.6 mol) of trimethyl borate is started to be added dropwise at a controlled temperature of -85°C to -75°C, and the dropwise addition is completed and the temperature is kept for 2.0 hours. The residual raw material of 2,3-difluoroanisole detected by liquid phase detection in the sample delivery was less than 0.5%.

[0028] After the reaction is complete, negative pressure precipitates tetrahydrofuran until the temperature of the reaction bottle reaches 50°C and there is no fl...

Embodiment 2

[0031] The first step: 1000mL four-neck bottle, equipped with a thermometer and a condenser, under the protection of nitrogen, put 63.3g (0.4mol) of 2,3-difluorophenethyl ether and 480mL of tetrahydrofuran, start stirring, and cool down to -85°C in a low-temperature bath At -75°C, 192 mL (0.48 mol) of n-butyl lithium in n-hexane (2.5 mol / L) was slowly added dropwise, and after the addition was complete, the mixture was stirred under temperature control for 2.0 hours. After the heat preservation is completed, 87.6 g (0.6 mol) of triethyl borate is started to be added dropwise at a controlled temperature of -85°C to -75°C, and the dropwise addition is completed and the temperature is kept for 2.0 hours. The residual raw material of 2,3-difluorophenetole was detected by liquid phase detection <0.5%.

[0032] After the reaction is complete, negative pressure precipitates tetrahydrofuran until the temperature of the reaction bottle reaches 50°C and there is no flow, stop the precip...

Embodiment 3

[0035] The first step: 1000mL four-neck bottle, equipped with a thermometer and a condenser, under the protection of nitrogen, put 63.3g (0.4mol) of 2,3-difluorophenetole and 480mL of tetrahydrofuran, start stirring, and cool down to -70°C in a low-temperature bath At -60°C, 192 mL (0.48 mol) of a cyclohexane solution of n-butyllithium (2.5 mol / L) was slowly added dropwise. After the addition was complete, the mixture was stirred at a controlled temperature for 2.0 hours. After the heat preservation is completed, 112.9 g (0.6 mol) of isopropyl borate is started to be added dropwise at a controlled temperature of -70° C. to -60° C., and the dropwise addition is completed and the temperature is kept for 2.0 hours. The residual raw material of 2,3-difluorophenetole was detected by liquid phase detection in sample delivery <0.5%.

[0036]After the reaction is complete, negative pressure precipitates tetrahydrofuran until the temperature of the reaction bottle reaches 50°C and ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com