High-wear-resistance water-based plastic coating and preparation method thereof

A plastic coating, high wear resistance technology, applied in conductive coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of insufficient adhesion and poor wear resistance of water-based coatings, and achieve excellent permeability and excellent mechanical properties. Performance, good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0048] Specific embodiment 1: A kind of highly wear-resistant water-resistant plastic coating in this embodiment is formed by mixing separately packaged component A and separately packaged component B during use; Mass ratio 1:1 mixed;

[0049] Described component A consists of 40 parts of water-based acrylic resin (model is SK6333), 25 parts of water-based silicone resin (model is SILRES MPF52SY409MK), 5 parts of alcohol ester twelve, 4 parts of dipropylene glycol methyl ether, 2 parts by mass parts Parts of propylene glycol, 0.2 parts of polyurethane, 0.6 parts of silicone (model BYK-034), 0.3 parts of anionic surfactant (model is Metolat 288), 2 parts of high molecular block polymer (model is TEGO Dispers 670), 0.6 parts Associative alkali swelling leveling agent, 1 part of phosphate ester copolymer (model is LB3055), 0.2 part of 2-amino-2 methyl-1-propanol (model is AMP-95), 0.4 part of benzimidazole compound ( The model is parmetol DF19), 5 parts of graphene and carbon na...

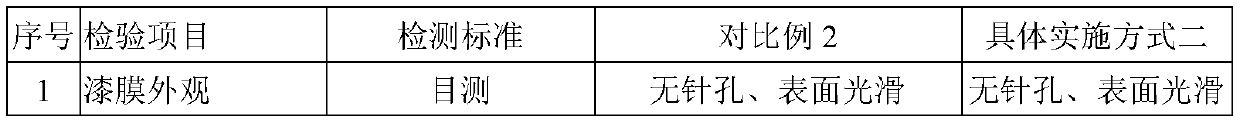

specific Embodiment approach 2

[0060] Specific embodiment two: A kind of high wear-resisting water-resistant plastic coating in this embodiment is formed by mixing separately packaged component A and separately packaged component B during use; Mass ratio 1:1 mixed;

[0061] Described component A consists of 38 parts of water-based polyurethane resin (model is PU-3333), 20 parts of water-based acrylic modified polyurethane resin (model is PUA-5870), 3 parts of alcohol ester twelve, 4 parts of di Propylene glycol methyl ether, 3 parts of dipropylene glycol butyl ether, 2 parts of propylene glycol, 0.2 parts of hydroxyethyl cellulose ether, 0.6 parts of silicone (model BYK-034), 0.3 parts of polyether modified silicone (model Wet 280 ), 3 parts of polymer block polymer (model is TEGO Dispers670), 0.5 part of associative alkali swelling leveling agent, 1 part of phosphate ester copolymer (model is LB3055), 0.2 part of dimethylethanolamine, 0.4 part of benzene It is prepared by imidazole compound (model is parm...

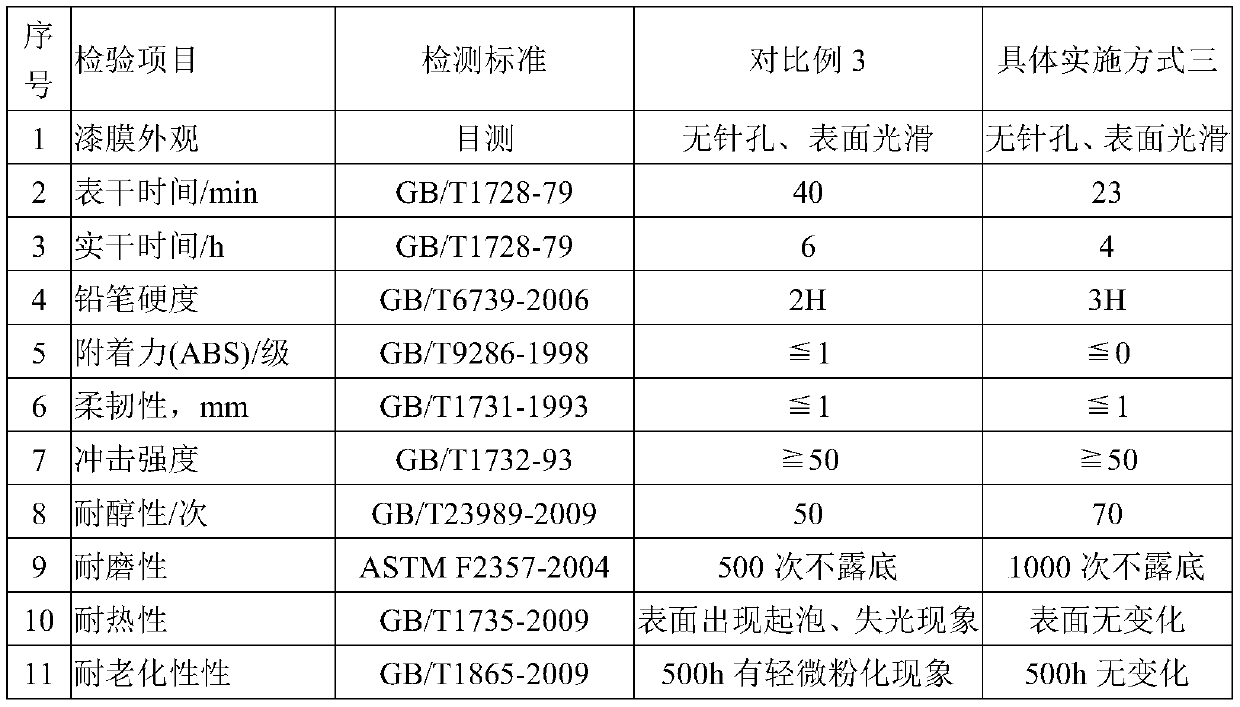

specific Embodiment approach 3

[0073] Specific embodiment three: A kind of high wear-resistant water-resistant plastic coating in this embodiment is formed by mixing separately packaged component A and separately packaged component B during use; Mass ratio 1:1 mixed;

[0074] Described component A is by mass parts by 40 parts of waterborne epoxy resins (model is EPIKOTE TM 3520-WY-55A), 25 parts of water-based fluorocarbon resin (model Kynar HSV900), 4 parts of alcohol ester twelve, 3 parts of dipropylene glycol methyl ether, 3 parts of propylene glycol, 0.3 parts of hydroxyethyl cellulose ether, 0.6 parts of silicon Oxane (model is DFM CP-8), 0.6 parts of nonionic surfactant (model is DAPRO U-99), 5 parts of hydrophobic polyphosphate (model is LM Colorol E), 0.8 parts of association type alkali swelling fluid Leveling agent, 2 parts of phosphate ester copolymer (model is LB3055), 0.2 parts of dimethylethanolamine, 0.4 parts of methylisothiazolinone (model is CMI / MI and N- / O-formal mixture A 26), 8 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com