UV spraying high-transmittance matte varnish and preparation method thereof

A topcoat, high-transparency technology, used in coatings, epoxy coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor texture and color, poor film transparency, and achieve high curing efficiency , Reduce paint volatilization, good matting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

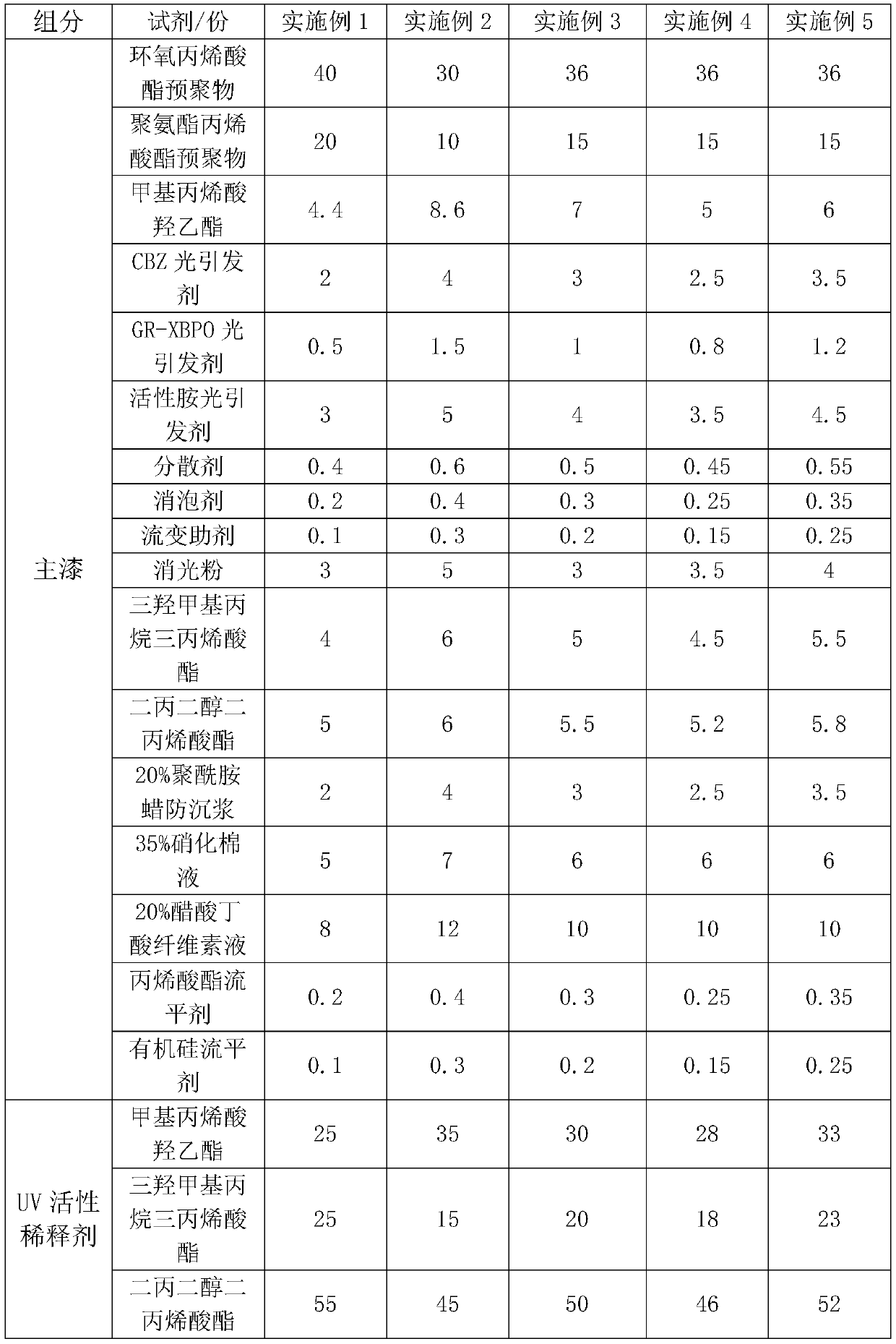

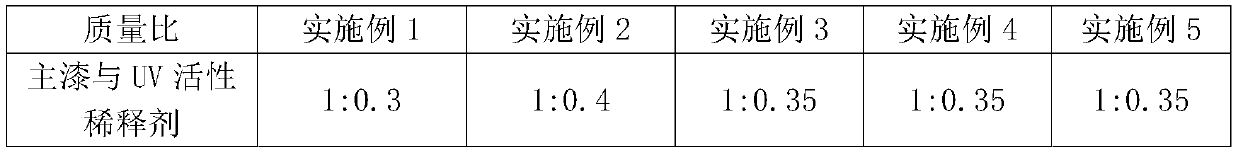

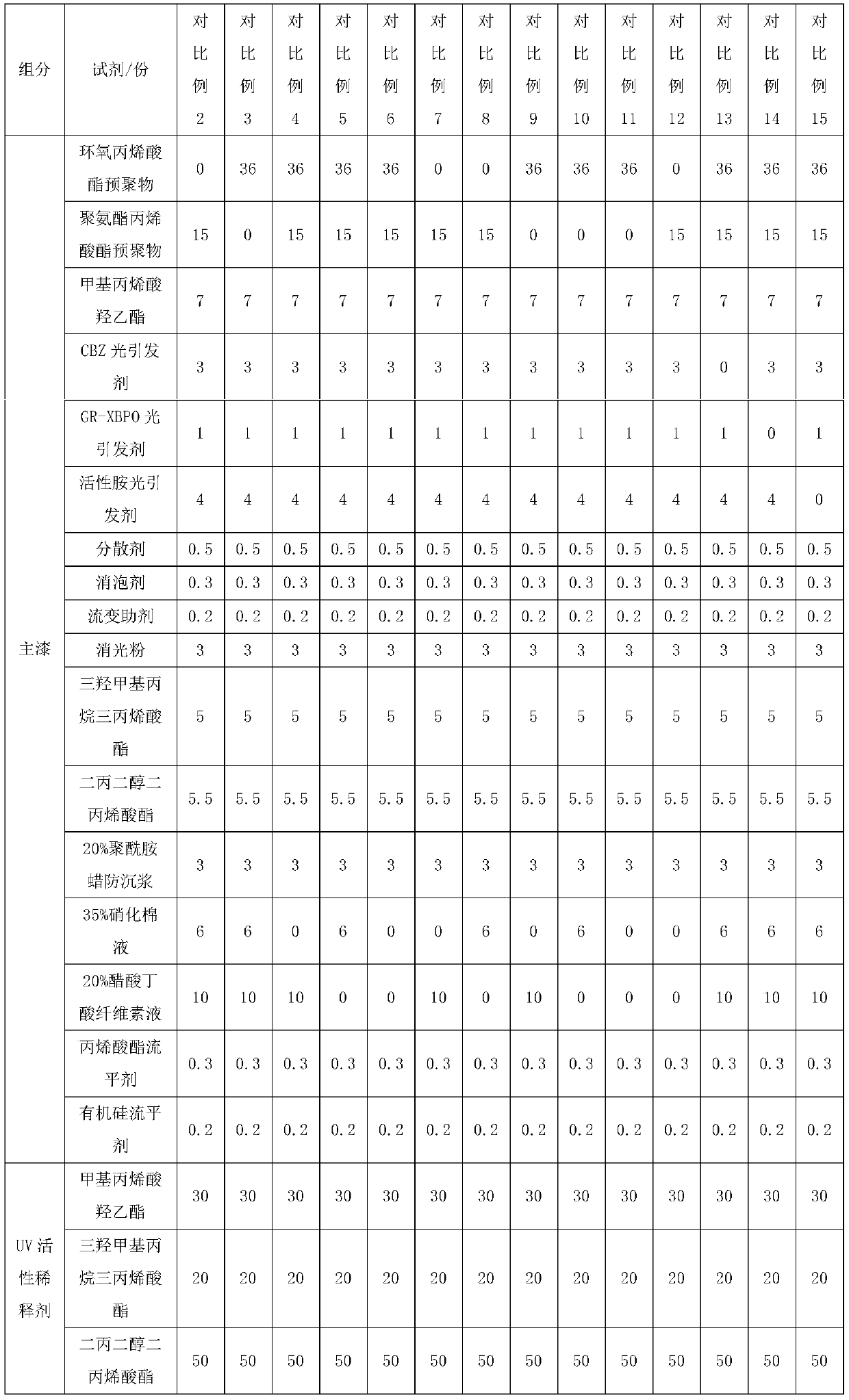

Examples

Embodiment 1-5

[0057] A kind of UV spraying high translucency matte varnish, it is prepared by following method:

[0058] (1) Prepare 20% polyamide wax anti-settling slurry: put 60 parts of xylene into the dispersion tank, then put 20 parts of polyamide wax into it, wash the side of the tank with 5 parts of xylene, and disperse 15 parts at a speed of 1200 to 1500 rpm. ~20 minutes until the fineness is ≤25μm, stop the machine and add the remaining 15 parts of xylene, stir evenly at a speed of 600-800 rpm for 8-10 minutes, filter with a 200-mesh filter, and put it into a bucket for use;

[0059] (2) Preparation of 35% nitrocellulose solution: put 10 parts of butyl acetate, 49 parts of ethyl acetate, and 1 part of nitrocellulose anti-yellowing agent into the dispersion tank and stir for 5-6 minutes at a speed of 600-800 rpm. Slowly put 35 parts of nitrocellulose into the dispersing tank, stir at a speed of 600-800 rpm for 5-6 minutes, then wash the edge of the tank with the remaining part of bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com