Coated microgel particle profile-control agent and preparation method thereof

A technology of microgel particles and profile control agent, which is applied to chemical instruments and methods, drilling compositions and other directions, can solve the problems of complex application process, high operating cost, difficulty in separation and purification, etc., and achieves simple preparation method, The effect of reducing commercial costs and extending expansion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] On the other hand, the present invention also provides a preparation method of coated microgel particle profile control agent, comprising the following steps:

[0037] S1: Dissolve acrylamide, acrylamide ionic monomer, acrylamide sugar monomer, crosslinking agent, initiator and stabilizer in deionized water to form a monomer solution, and use an alkaline substance to dissolve the monomer solution The pH value is adjusted to be neutral;

[0038] S2: adding hydrophobic nanomaterials to the monomer solution, and stirring evenly at a high speed of at least 12000 rpm to obtain a dry powder coating body pre-reaction system;

[0039] S3: The pre-reaction system of the dry powdery coating body is subjected to nitrogen deoxygenation for 20-40 minutes, then the temperature is raised to 35-40° C., and the reaction is performed at a constant temperature for 4-8 hours under the protection of nitrogen;

[0040] S4: Drying the pre-reaction system of the dry powder coated body to obta...

Embodiment 1

[0044] A method for preparing a coated microgel particle profile control agent, comprising the following steps:

[0045] 1) Add 25g of acrylamide, 5g of acrylic acid, 0.8g of vinyl glycoside, 0.05g of N,N'-methylenebisacrylamide, 0.03g of potassium persulfate, 0.03g of sodium bisulfite, and 0.1g of chlorine into a 250mL beaker NaCl and 60g deionized water, after stirring and dissolving, adjust the pH value of the solution to neutrality with sodium hydroxide;

[0046] 2) Pour the solution into a mechanical stirrer, then weigh 10 g of hydrophobic nano-titanium dioxide and add it to the mechanical stirrer, turn on the mechanical stirrer, and stir for 90 seconds at a speed of 18000 rpm to obtain a white dry powder packet. Covering pre-reaction system;

[0047] 3) Transfer the pre-reaction system to a 250mL three-necked flask, pass nitrogen gas to remove oxygen for 30 minutes, then raise the temperature to 40°C, and react at a constant temperature for 4 hours under the protection ...

Embodiment 2

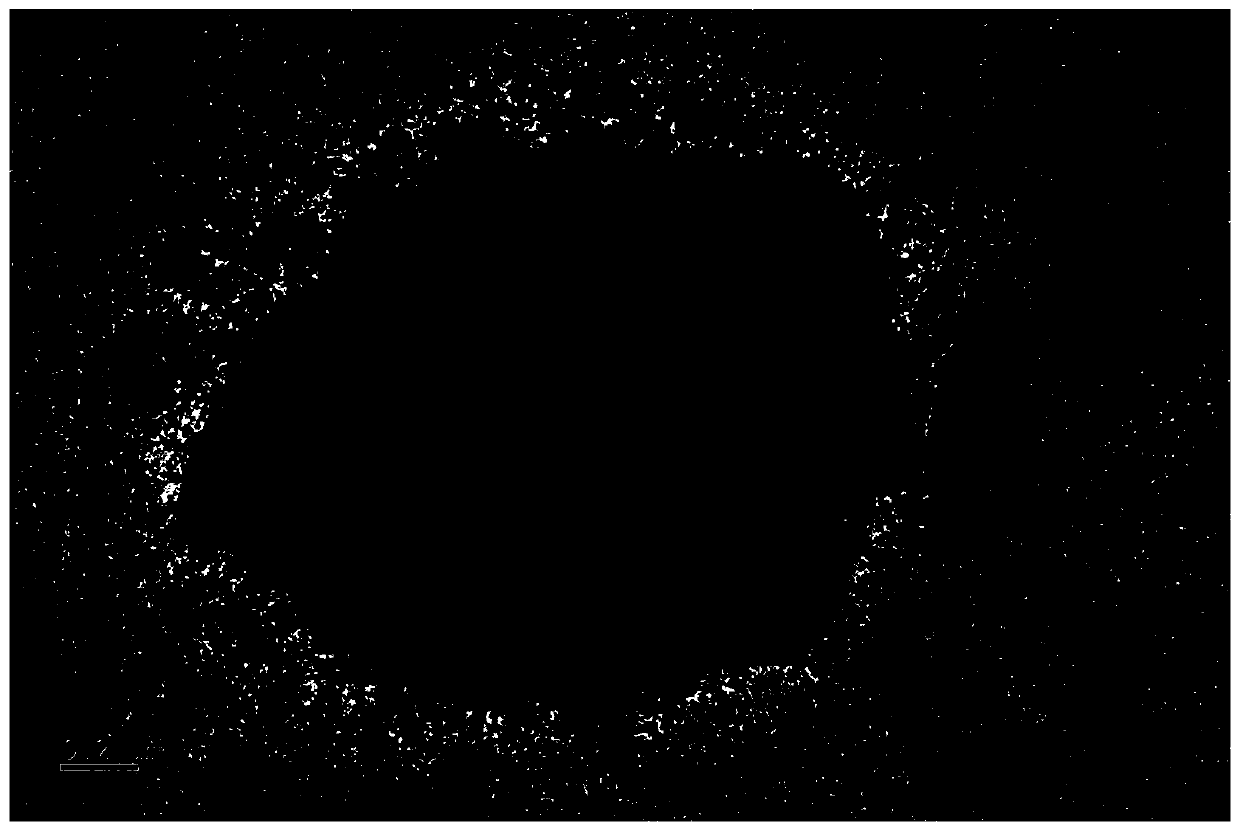

[0050] Observing the coating type microgel particle profile control agent that embodiment 1 makes under transmission electron microscope, the transmission electron microscope figure of described coating type microgel particle profile control agent is as follows figure 1 shown. From figure 1 It can be seen that the coated microgel particle profile control agent presents a shell-core morphological structure. The coating layer on the surface of the coated microgel particle profile control agent is mainly composed of hydrophobic nano-titanium dioxide stacks, and the interior is a gel core.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com