Silicon-based stress covariant substrate and preparation method thereof, gallium nitride LED and preparation method thereof

A technology of stress covariant layer and gallium nitride, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effect of material size expansion, simple and practical process, and conducive to large-scale production and application promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

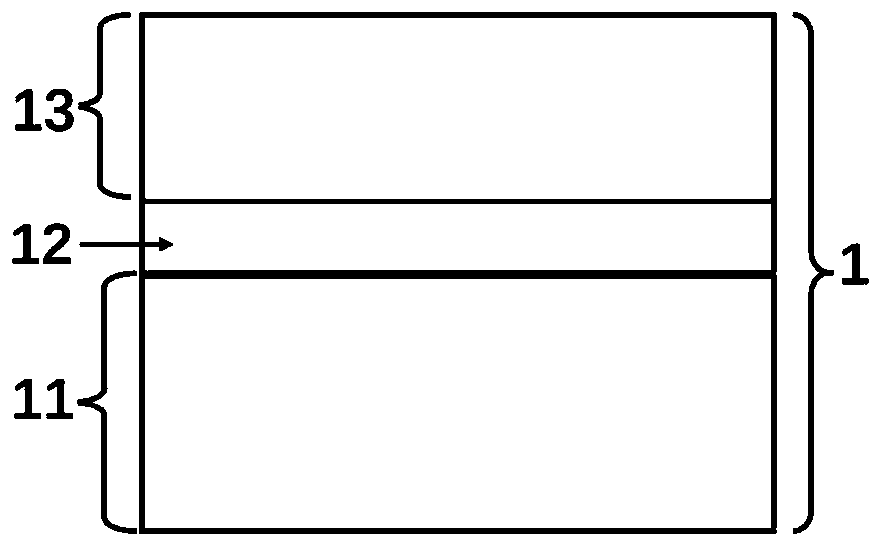

[0040] The invention discloses a silicon-based stress-covariant substrate, such as figure 1 As shown, it includes: a double-sided polished silicon (Si) single crystal substrate 11; a thin zirconium nitride (ZrN) conductive reflective stress covariant layer 12; a gallium nitride (GaN) single crystal thin film template layer 13.

[0041] The diameter of the double-sided polished silicon single crystal substrate includes but is not limited to 2 inches, 4 inches, 6 inches, 8 inches, 12 inches, and 18 inches.

[0042] The thin zirconium nitride conductive reflective stress-covariant layer 12 is formed on the double-sided polished silicon single crystal substrate 11, and is composed of a thin zirconium nitride (ZrN) film material with a thickness of 50nm to 350nm, which is used for transferring and coordinating the release of silicon (Si) Lattice mismatch stress, internal stress and thermal mismatch stress generated during the process of substantial cooling of gallium nitride (GaN) ...

Embodiment 2

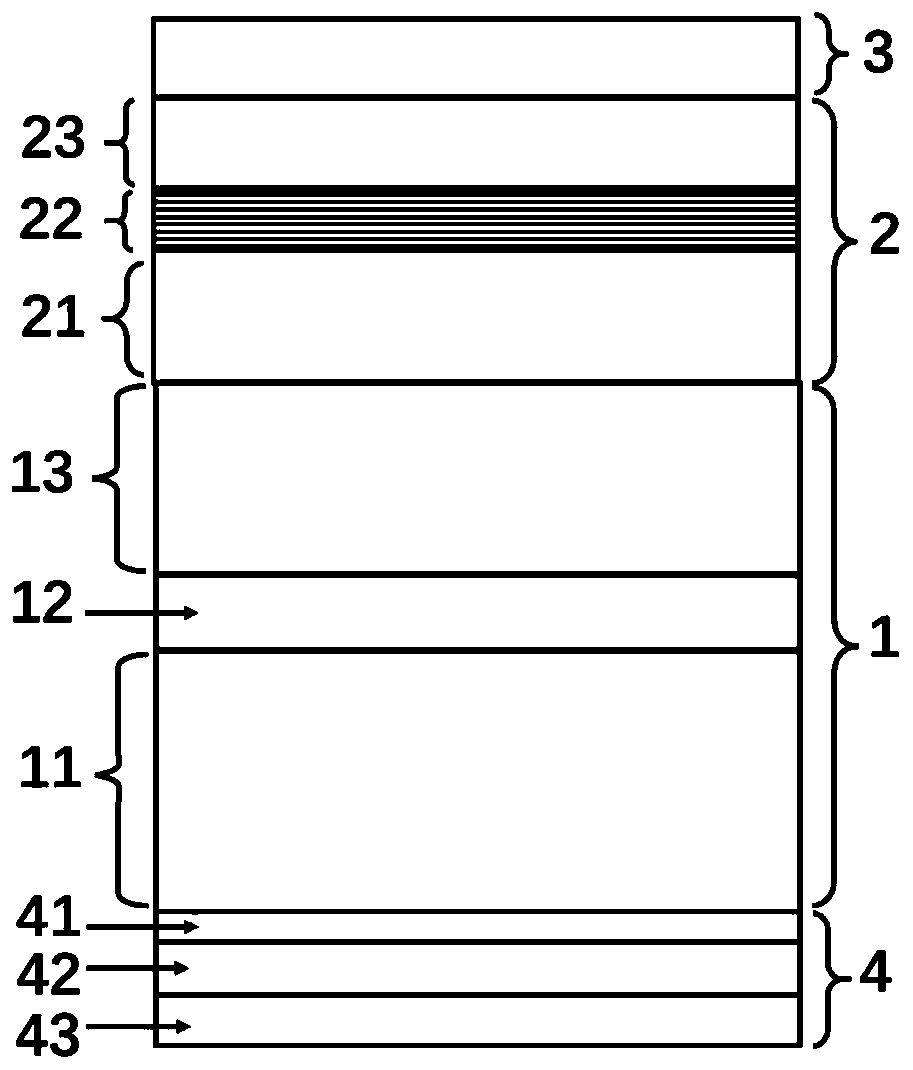

[0058] Silicon (Si) single-crystal substrate 11, thin zirconium nitride (ZrN) conductive light-reflecting stress-conforming layer 12, thin gallium nitride (GaN) single-crystal thin-film template layer 13, and the silicon (Si)-based stress-conforming layer composed of the three Variable substrate 1, which can be used for single crystal thin films of gallium nitride, indium nitride, indium gallium nitride, indium aluminum gallium nitride, indium aluminum nitride, aluminum gallium nitride, aluminum nitride, zinc oxide, silicon carbide and boron nitride Epitaxial growth of materials can provide homogeneous gallium nitride (GaN) single crystal substrate templates without cracks, low dislocation density, low stress or even stress-free; it can be used to prepare vertical structure gallium nitride optoelectronic devices including but not limited to Gallium LEDs, gallium nitride lasers and gallium nitride photodetectors; the emission wavelengths and light absorption wavelengths of galli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com