Flexible composite substrate for perovskite thin-film solar cell and preparation method thereof

A technology for solar cells and composite substrates, applied in the field of solar cells, can solve the problems of inability to block water and oxygen, poor environmental adaptability, poor temperature resistance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

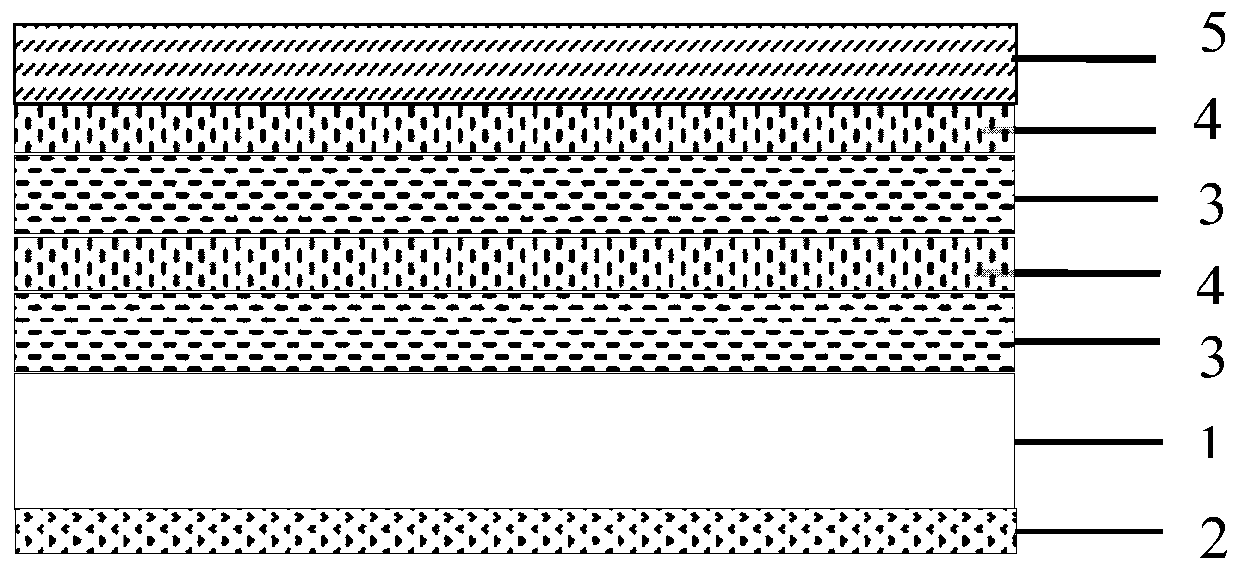

[0033] The present invention also provides a method for preparing a flexible perovskite thin-film solar cell, comprising the following steps:

[0034] (1) Use UV-O on the outer surface of the flexible substrate 3 , O 2 -Plasma or plasma treatment, after treatment, wet coating process is used to deposit inorganic nano-coating. Wet coating processes include, but are not limited to, microgravure coating, slot coating, roll coating, spray coating, blade coating, or screen printing.

[0035] (2) Treat the inner surface of the base material, and the treatment method is the same as step (1). An organic barrier layer is deposited on the inner surface, and an inorganic barrier layer is deposited on the surface of the organic barrier layer. After one or more paired layers are deposited, the preparation of the water-oxygen barrier layer is completed. The flexible substrate can be a substrate or a substrate / planarization layer, and the planarization layer can reduce the surface roughne...

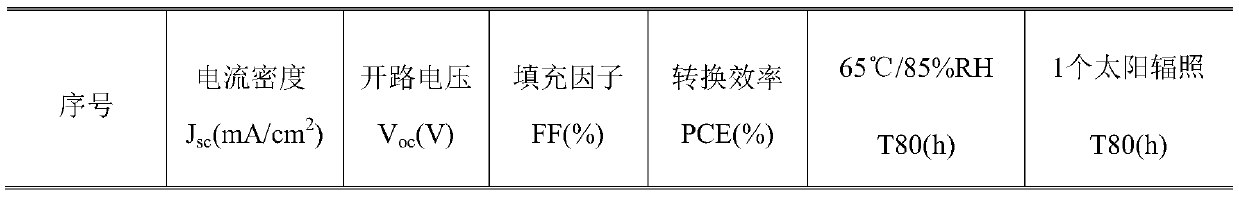

Embodiment 1

[0040] The first step is to prepare the water-oxygen barrier layer:

[0041] With 50μm ETFE film as the substrate, O 2 -plasma treatment of the outer surface of the substrate, micro gravure coating 20wt% SiO 2 Hydrosol, obtain 50nm SiO 2 Inorganic nanocoating. The inner surface of the substrate is then treated with plasma, coated with a planarization layer, and then SiN is deposited using PECVD equipment x Inorganic barrier layer with a thickness of 150nm; followed by vacuum coating of organic silicon-modified polyacrylate organic barrier layer with a thickness of 10μm; again using PECVD equipment to deposit SiN with a thickness of 150nm x The inorganic barrier layer completes the preparation of the water and oxygen barrier layer. WVTR is 1×10 -5 g / m 2 / day.

[0042] The second step is to prepare transparent electrodes:

[0043] On the surface of the water-oxygen barrier layer prepared in the first step, a 180nm thick ITO transparent conductive film was prepared by mag...

Embodiment 2

[0058] The first step is to prepare the water-oxygen barrier layer:

[0059] With 125μm UV cut-off transparent PVDF film as the base material, the outer surface is treated by corona, and 25wt% Al is slot-coated 2 o 3 Hydrosol, to obtain 100nm Al 2 o 3 Inorganic nanocoating. The inner surface of the substrate is treated with plasma, coated with a planarization layer, and then SiO is deposited using PECVD equipment x C y Inorganic barrier layer with a thickness of 200nm; then coated with a silicone-modified polyacrylate organic barrier layer with a thickness of 2μm; again using PECVD equipment to deposit 200nm thick SiO x C y The inorganic barrier layer completes the preparation of the water and oxygen barrier layer. WVTR is 1×10 -4 g / m 2 / day.

[0060] The second step is to prepare transparent electrodes:

[0061] On the surface of the water-oxygen barrier layer prepared in the first step, a 100nm silver nanowire AgNWs transparent conductive film was prepared by wet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com