High-performance silicon-carbon composite negative electrode material with adjustable and controllable particle size and preparation method thereof

A silicon-carbon composite and negative electrode material technology, applied in the direction of negative electrodes, active material electrodes, battery electrodes, etc., can solve the problem of electrochemical indicators, particle structure, morphology, and particle size that affect the capacity, rate, and cycle performance of lithium-ion batteries. Poor performance, poor dispersion effect and poor electronic conductivity, etc., to ensure consistent particle size, improve cycle stability, and reduce production and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

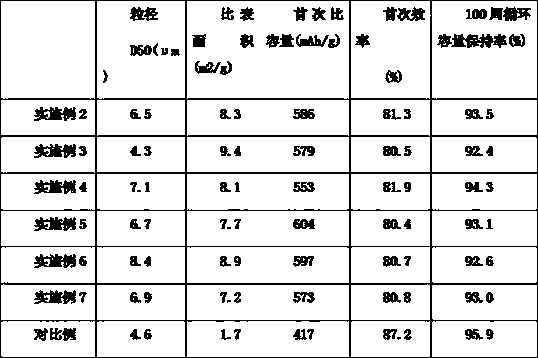

Examples

Embodiment 1

[0018] A silicon-carbon composite anode material with high performance and adjustable particle size, including an inner core and a coating layer coated outside the inner core, the inner core is nano-silicon, and the coating layer is arranged sequentially from the inside to the outside. A first carbon coating layer and a second carbon coating layer, the hardness of the first carbon coating layer is less than that of the second carbon coating layer.

[0019] Specifically, one or more of high-purity silicon powder, polycrystalline silicon powder or monocrystalline silicon powder can be used for nano-silicon, and the particle size D50=50-250nm. The first carbon coating layer is obtained by low-temperature carbonization of pitch or paraffin, the softening point of the pitch is 80-280°C, and the particle size D50=1-10 μm; the second carbon coating layer is obtained by high-temperature carbonization of organic carbon sources. Wherein, the organic carbon source is one or more of pheno...

Embodiment 2

[0029] S1: Mix nano-silicon with a medium particle size of D50=150nm and asphalt with a softening point of 250°C in a high-speed mixer at a mass ratio of 100:50, and then disperse the mixed powder in ethanol to obtain a mixed slurry;

[0030] S2: Put the mixed slurry in a ball mill and grind it for 1 hour at a rotational speed of 1000r / min, and vacuum freeze-dry the obtained mixed slurry at -20°C to obtain a composite powder of organic carbon source-coated nano-silicon powder body;

[0031] S3: Put the composite powder in a fusion device with a rotating speed of 300r / min and fuse at a low speed for 25 minutes to obtain a composite coating with a high degree of spheroidization;

[0032] S4: Put the composite coating into a tube furnace, heat up to 600°C at 3°C / min for carbonization for 2 hours, and pass through a 200-mesh screen to obtain a composite precursor after cooling down;

[0033] S5: Mix the composite precursor with 5% hard carbon coating amount and phenolic resin in ...

Embodiment 3

[0036] S1: Mix nano-silicon with a medium particle size of D50=150nm and asphalt with a softening point of 250°C in a high-speed mixer at a mass ratio of 100:50, and then disperse the mixed powder in ethanol to obtain a mixed slurry;

[0037] S2: Put the mixed slurry in a ball mill and grind it for 4 hours at a rotational speed of 1000r / min, and vacuum freeze-dry the obtained mixed slurry at -20°C to obtain a composite powder of organic carbon source-coated nano-silicon powder body;

[0038] S3: Put the composite powder in a fusion device with a rotating speed of 300r / min and fuse at a low speed for 25 minutes to obtain a composite coating with a high degree of spheroidization;

[0039] S4: Put the composite coating into a tube furnace, heat up to 600°C at 3°C / min for carbonization for 2 hours, and pass through a 200-mesh screen to obtain a composite precursor after cooling down;

[0040] S5: Mix the composite precursor with 5% hard carbon coating amount and phenolic resin in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com