Preparation method of carbon nanosheet, positive electrode material and preparation method thereof

A technology of carbon nanosheets and cathode materials, applied in the field of nanomaterials, can solve the problems of uncontrollable, high cost, and single shape, and achieve the effects of inhibiting volume expansion, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] On the one hand, the embodiment of the present invention provides a method for preparing carbon nanosheets, the preparation method comprising the following steps:

[0041] S01: Provide aluminum source and 4,4'-biphenyl dicarboxylic acid;

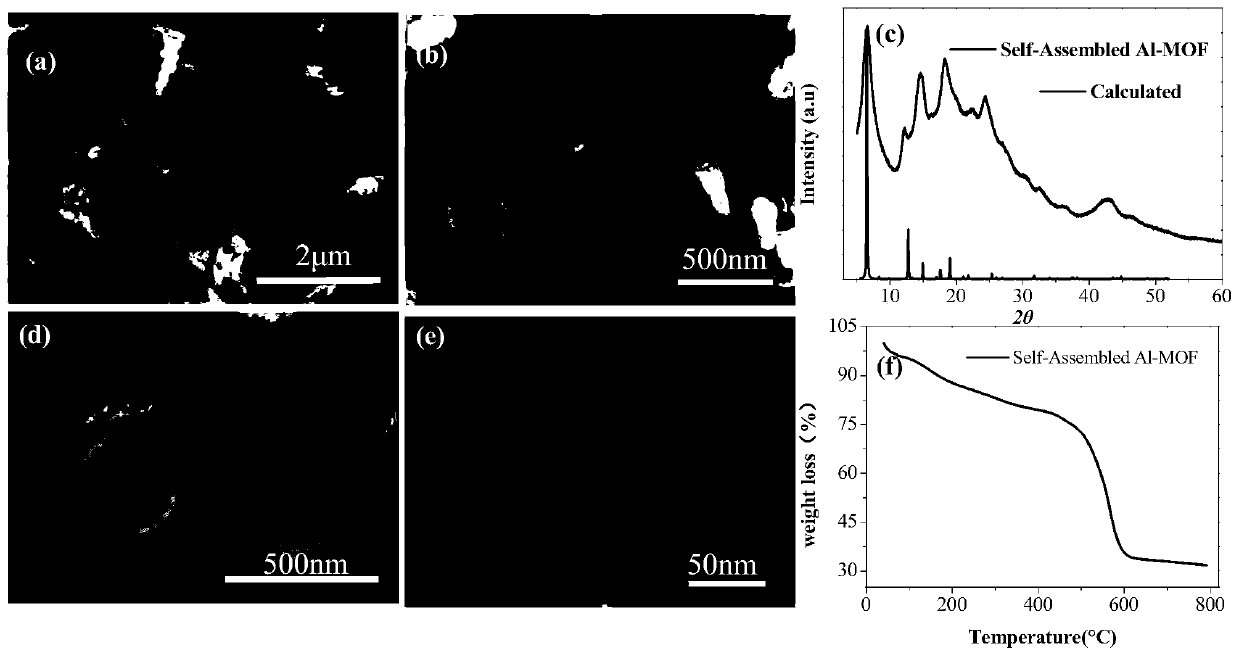

[0042] S02: Dissolving the aluminum source and 4,4'-biphenyldicarboxylic acid in an organic solvent for heat treatment, followed by solid-liquid separation to obtain a self-assembled aluminum-based metal-organic framework;

[0043] S03: subjecting the Al-based metal-organic framework to carbonization treatment and acid treatment in sequence, and then drying to obtain carbon nanosheets.

[0044] In the preparation method of carbon nanosheets provided in the embodiments of the present invention, aluminum source and 4,4'-biphenyl dicarboxylic acid are dissolved in an organic solvent and heated to form a self-assembled aluminum-based metal-organic framework (Al-MOF). The aluminum-based metal-organic framework superstructure is used as a ...

Embodiment 1

[0054] (1) Preparation of Al-MOF-1 precursor:

[0055] Weigh 0.130842g Al(NO 3 ) 3 9H 2 O and 0.2828g 4,4'-biphenyldicarboxylic acid are placed in a beaker, 50ml of DMF solution is added, and the beaker is placed on a magnetic stirrer, stirred for 30min, and the fully stirred solution is transferred to a 20ml polytetrafluoroethylene bottle In the body, heated at 120°C for 24h, naturally cooled to room temperature, centrifuged to obtain a white precipitate, dried at 70°C-200°C and ground to obtain a white powder, which is a self-assembled aluminum-based metal-organic framework.

[0056] (2) Preparation of carbon nanosheets:

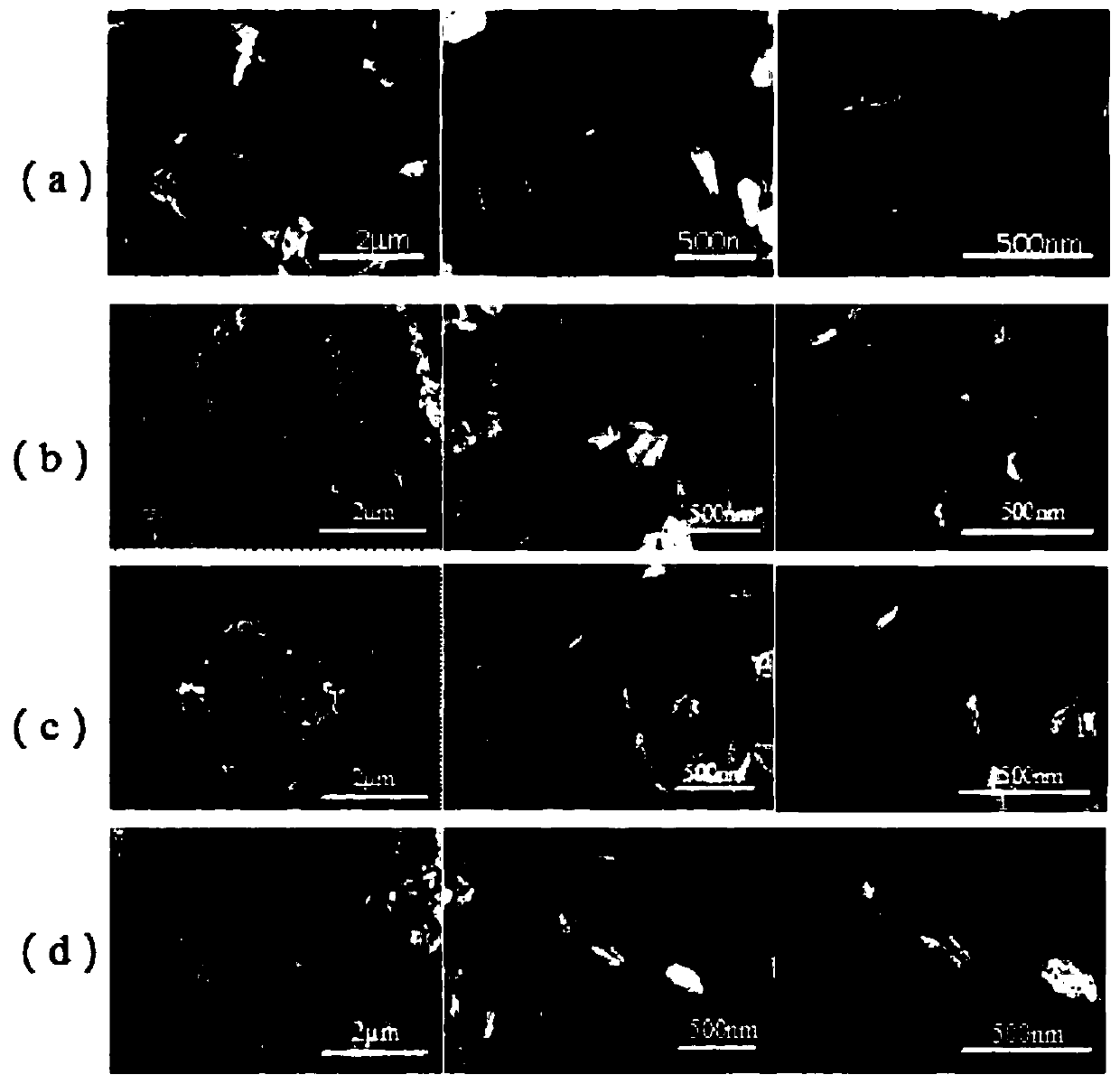

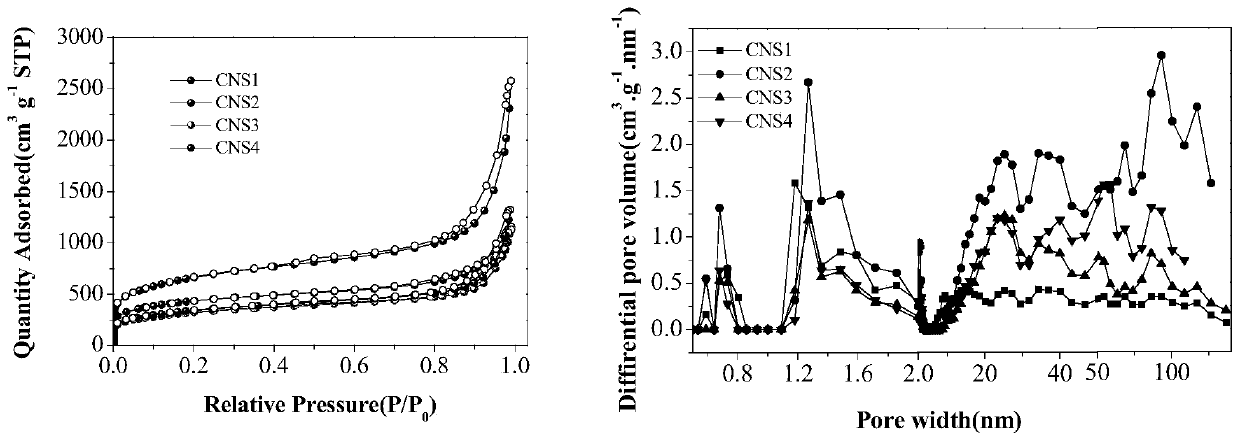

[0057] Put the above-mentioned Al-MOF1 precursor into a tube furnace, and carry out carbonization under the protection of Ar gas at 700°C. The heating rate is 5°C / min, and the constant temperature time is 1h. When the constant temperature is over, it is naturally cooled to room temperature. Put into hydrochloric acid solution (10wt%), ultrasonic 30min,...

Embodiment 2

[0061] (1) Preparation of Al-MOF-2 precursor:

[0062] Weigh 0.0651g Al(NO 3 )3 9H 2 O and 0.1401g 4,4'-biphenyldicarboxylic acid are placed in a beaker, 50ml of DMF solution is added, and the beaker is placed on a magnetic stirrer, stirred for 30min, and the fully stirred solution is transferred to a 10ml polytetrafluoroethylene bottle , heated at 120°C for 24 hours, naturally cooled to room temperature, centrifuged to obtain a white precipitate, dried at 70°C-200°C and ground to obtain a white powder.

[0063] (2) Preparation of carbon nanosheets:

[0064] Put Al-MOF2 into a tube furnace, carbonize under the protection of Ar gas at 700°C, the heating rate is 5°C / min, and the constant temperature time is 1h. When the constant temperature is over, it will naturally cool down to room temperature. solution (10wt%), sonicated for 30min, the mixture was sealed in an autoclave with a polytetrafluoroethylene liner at a constant temperature of 80°C for two days, finally centrifuge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com