High-precision filter felt and preparation method thereof

A filter felt, high-precision technology, applied in the field of filtration, can solve the problems of poor wear resistance, high preparation cost, and high application cost, and achieve the effects of improving wear resistance, improving mechanical strength, and reducing filtration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

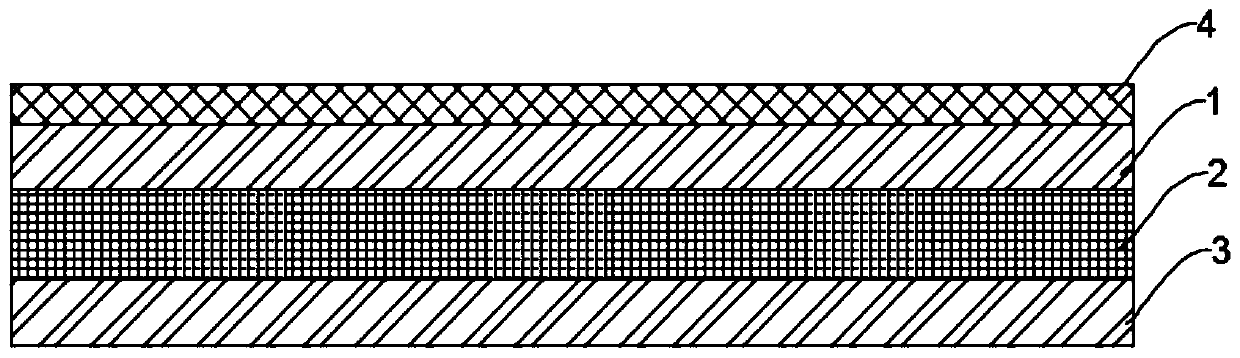

Image

Examples

preparation example Construction

[0025] A method for preparing a high-precision filter felt provided by an embodiment of the present invention is characterized in that it comprises the following steps:

[0026] S1, after the low-melting point polyester fiber is opened, it is fed into a carding machine to obtain a polyester fiber fleece.

[0027] In this embodiment, the low-melting point polyester fiber can be selected from commercially available low-melting point PET polyester fiber, and the melting point of the low-melting point polyester fiber is preferably 110-180°C. Through opening treatment, the fibers are in a fluffy state.

[0028] In this step, the input line speed of the carding machine is 1.6-2.6m / min, and the amount of fed fiber is 4-6kg / m 2 , the frequency is 300~600rpm / min.

[0029] S2. Opening the basalt fiber and the polypropylene fiber respectively, and then mixing to obtain a mixed fiber, and feeding the mixed fiber into a carding machine to obtain a mixed fiber fleece.

[0030] In this st...

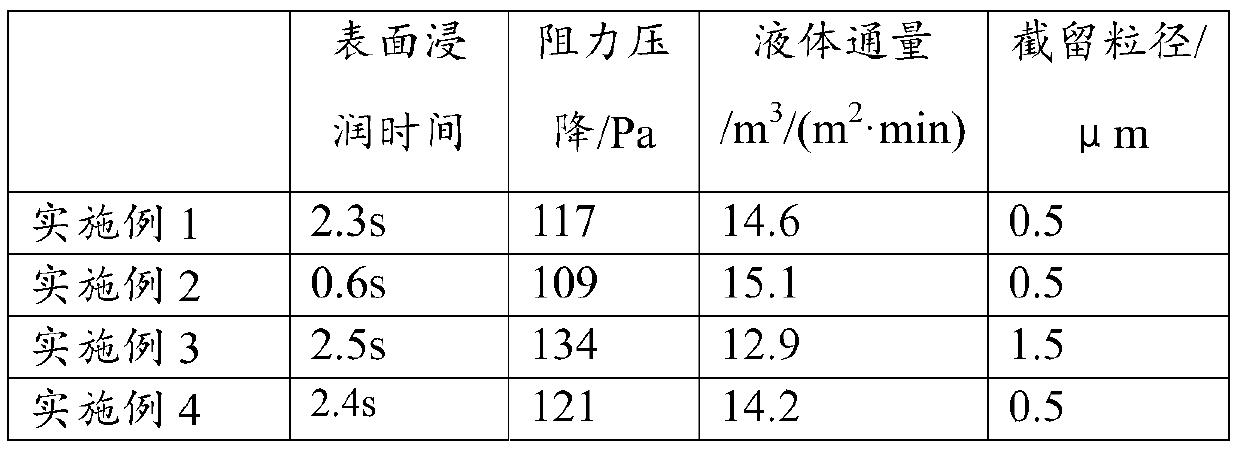

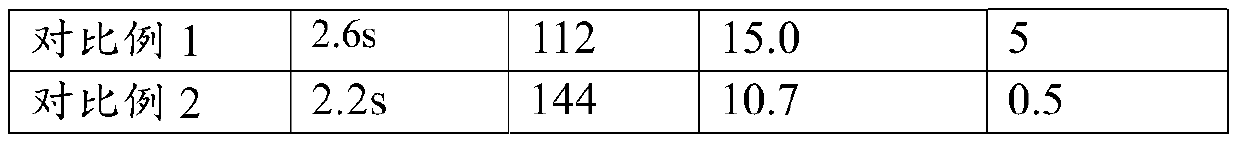

Embodiment 1

[0053] A high-precision filter felt provided in this embodiment is prepared according to the following steps:

[0054] (1) After the low-melting point polyester fiber of 0.98dtex is opened and processed, it is fed into a carding machine to obtain a polyester fiber fleece. The input line speed of the carding machine is 2.2m / min, and the amount of fed fiber is 5kg / m 2 , the frequency is 400rpm / min.

[0055] (2) After the 4dtex basalt fiber and the 4dtex polypropylene fiber are respectively opened, they are mixed according to a weight ratio of 1:2 to obtain a mixed fiber, and the mixed fiber is fed into a carding machine to obtain a mixed fiber fleece. The parameters of the mixed fiber in the carding machine are: the input line speed is 1.0m / min, and the amount of fed fiber is 7kg / m 2 , the frequency is 400rpm / min.

[0056] (3) the mixed fiber fleece that step (2) obtains is after soaking 25min in the aqueous solution of polydimethyldiallyl ammonium chloride and sodium chlorid...

Embodiment 2

[0063] A high-precision filter felt provided in this embodiment is prepared according to the following steps:

[0064] (1) obtain needle-punched filter felt according to the steps (1)-(7) of embodiment 1;

[0065] (2) Immerse the needle-punched filter felt in isopropanol for 40 minutes, and then coat the surface of the needle-punched filter felt with β-cyclodextrin and citric acid at a mass ratio of 1:1.2-1.5:0.1-0.3 And the hydrophilic solution of sodium hypophosphite, after coating, place it at 105°C for 1.5h. Wherein, the hydrophilic solution containing β-cyclodextrin contains β-cyclodextrin, citric acid and sodium hypophosphite in a mass ratio of 1:1.4:0.2.

[0066] (3) hot-rolling the needle-punched filter felt obtained in step (2), so that the polyester fibers on the surface are plasticized to form a microporous fiber membrane layer. The hot rolling temperature is 220° C., and the hot rolling pressure is 0.5 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com