Coal chemical industry solid waste drying tail gas treatment device and treatment method

A technology of coal chemical industry and exhaust gas, which is applied in the direction of chemical instruments and methods, combined devices, gas treatment, etc., can solve the problems of high loss on ignition, difficult solid waste treatment, unsuitable concrete, etc., and achieves low environmental impact rate and low resource consumption. The effect of high utilization rate and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

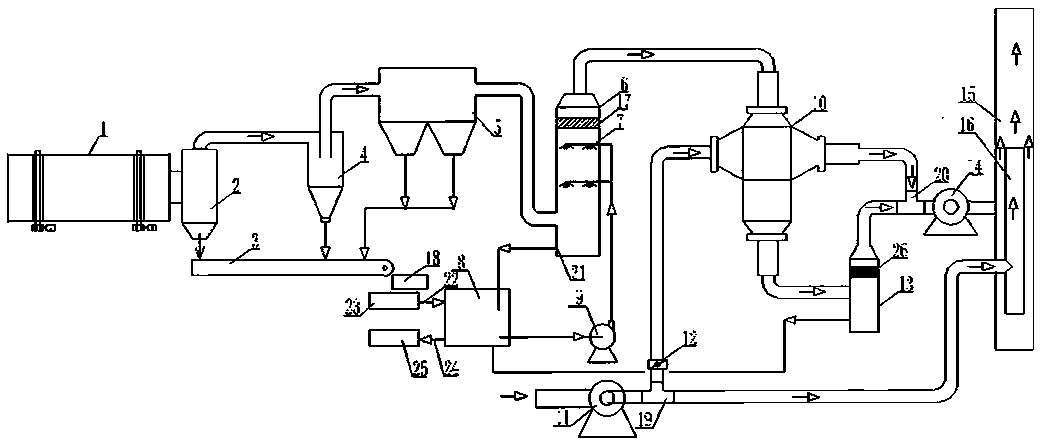

[0046] A coal chemical solid waste drying tail gas treatment device, including a dryer 1, a dry ash discharge device 2 is installed at the end of the dryer 1, and the bottom of the dry ash discharge device 2 is connected to the finished product through a dry ash conveying device 3 The gas outlet at the top of the dry ash discharge device 2 is connected to the odor absorption tower 6 through the dust removal unit, and the gas phase outlet of the odor absorption tower 6 is connected to the flue gas condensate collector through the tube side of the gas-gas heat exchanger 10 13 connected, the gas phase outlet of the flue gas condensate collector 13 is connected with the outer cylinder of the telescopic chimney 15; The tuyeres are connected, and the second tee 20 and the system induced draft fan 14 are arranged in turn between the gas phase outlet of the flue gas condensate collector 13 and the outer cylinder of the sleeve chimney 15, and the shell side outlet of the gas-gas heat ex...

Embodiment 2

[0062] A coal chemical solid waste drying tail gas treatment device, including a dryer 1, a dry ash discharge device 2 is installed at the end of the dryer 1, and the bottom of the dry ash discharge device 2 is connected to the finished product through a dry ash conveying device 3 The gas outlet at the top of the dry ash discharge device 2 is connected to the odor absorption tower 6 through the dust removal unit, and the gas phase outlet of the odor absorption tower 6 is connected to the flue gas condensate collector through the tube side of the gas-gas heat exchanger 10 13 connected, the gas phase outlet of the flue gas condensate collector 13 is connected with the outer cylinder of the telescopic chimney 15; The tuyeres are connected, and the second tee 20 and the system induced draft fan 14 are arranged in turn between the gas phase outlet of the flue gas condensate collector 13 and the outer cylinder of the sleeve chimney 15, and the shell side outlet of the gas-gas heat ex...

Embodiment 3

[0078]A coal chemical solid waste drying tail gas treatment device, including a dryer 1, a dry ash discharge device 2 is installed at the end of the dryer 1, and the bottom of the dry ash discharge device 2 is connected to the finished product through a dry ash conveying device 3 The gas outlet at the top of the dry ash discharge device 2 is connected to the odor absorption tower 6 through the dust removal unit, and the gas phase outlet of the odor absorption tower 6 is connected to the flue gas condensate collector through the tube side of the gas-gas heat exchanger 10 13 connected, the gas phase outlet of the flue gas condensate collector 13 is connected with the outer cylinder of the telescopic chimney 15; The tuyeres are connected, and the second tee 20 and the system induced draft fan 14 are arranged in turn between the gas phase outlet of the flue gas condensate collector 13 and the outer cylinder of the sleeve chimney 15, and the shell side outlet of the gas-gas heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com