Glucosamine hyaluronate and application thereof

A technology of hyaluronate and glucosamine, which is applied in the field of glucosamine hyaluronate and its application, to achieve good therapeutic effect, safe application and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

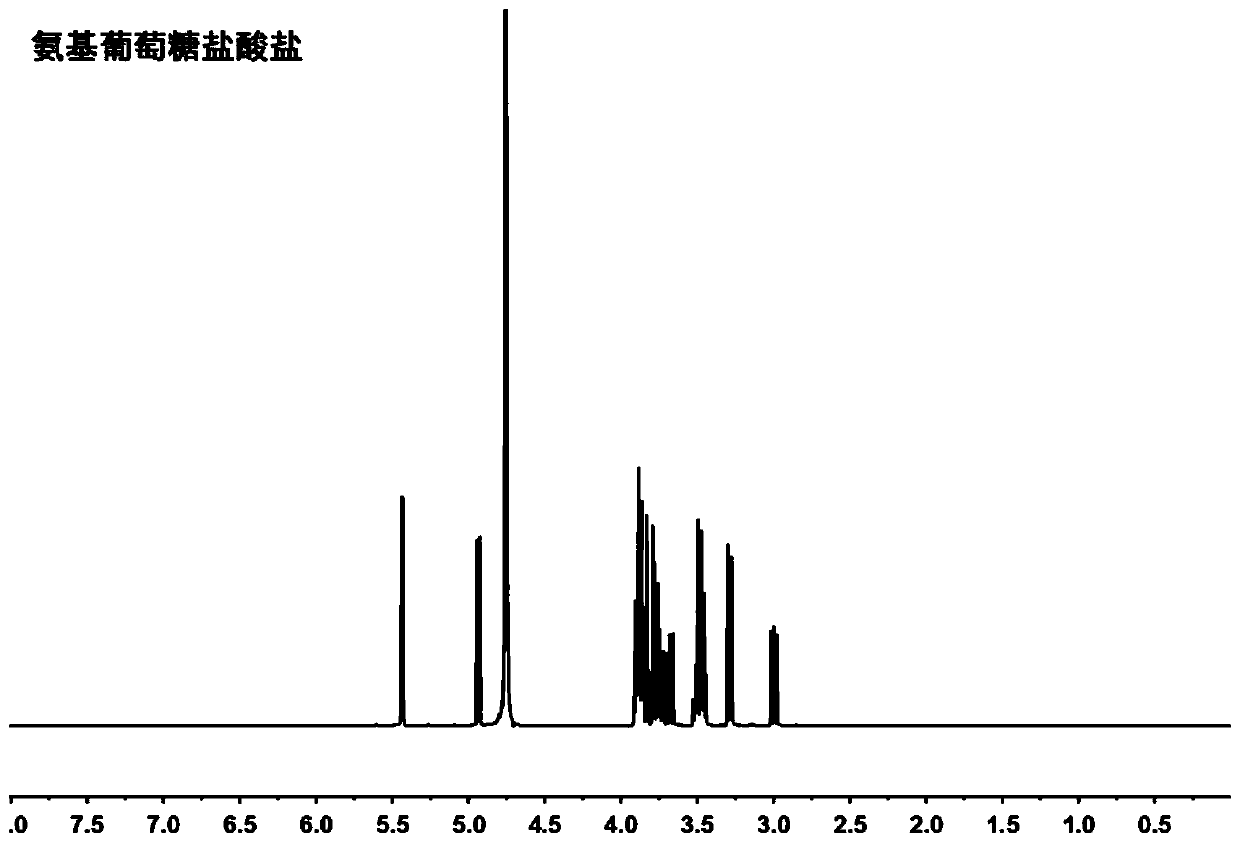

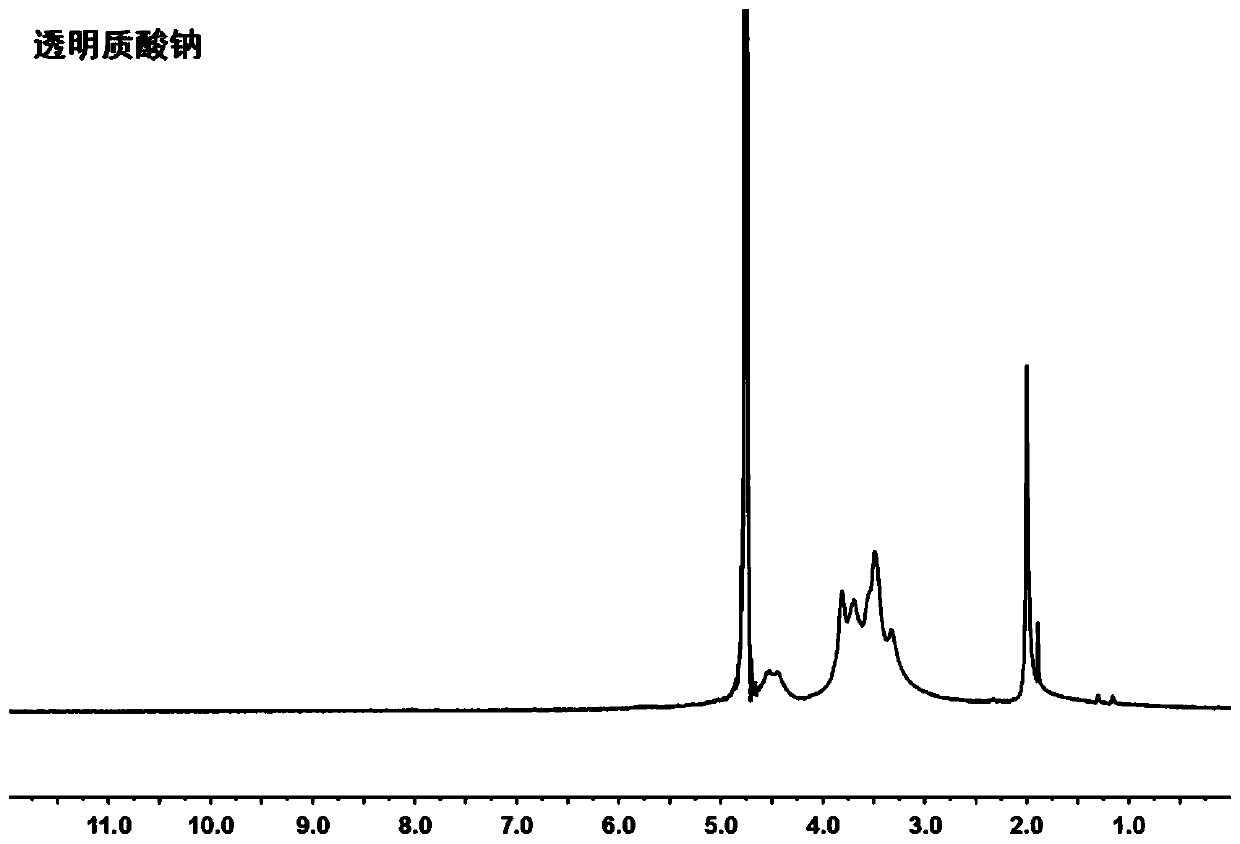

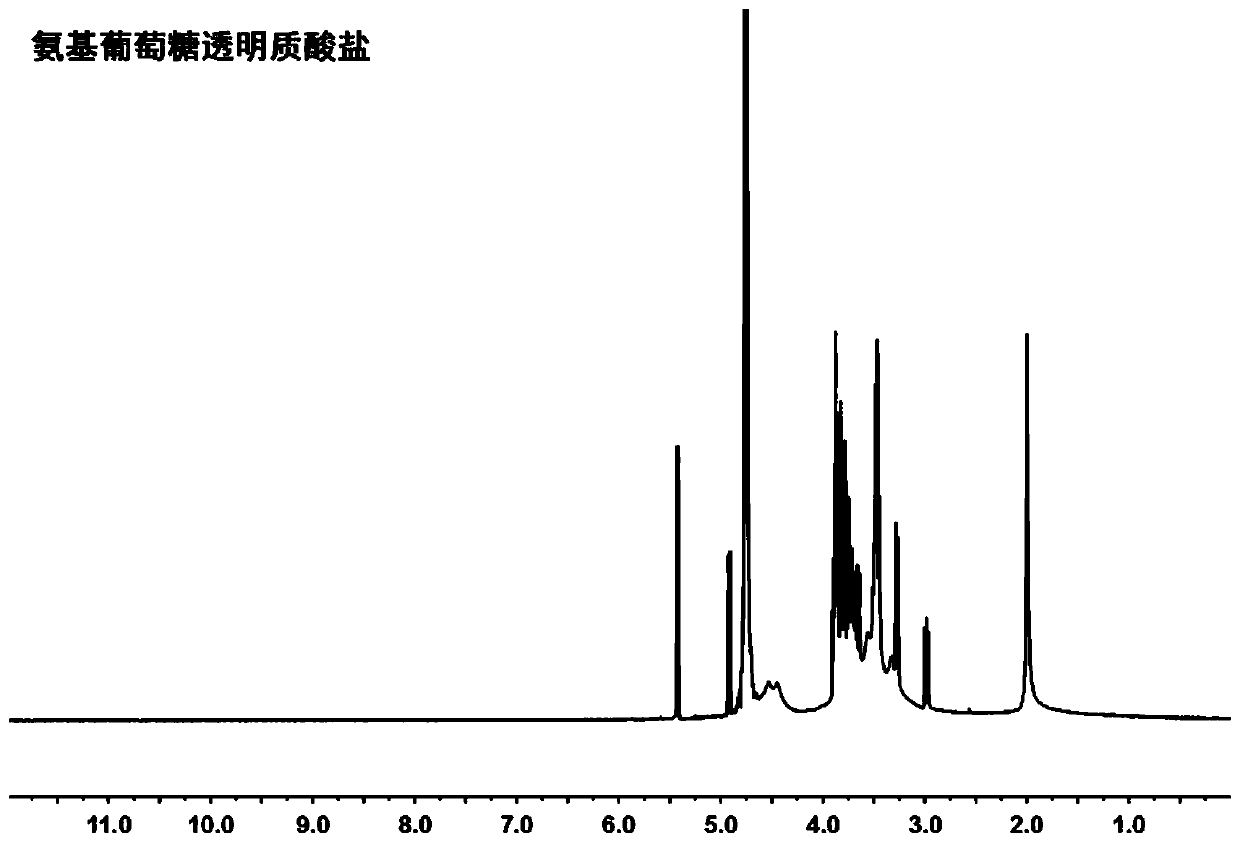

Image

Examples

Embodiment 1

[0030] Weigh 5 g of hyaluronic acid with a molecular weight of 100,000 and 5 g of glucosamine hydrochloride, dissolve them in water, dialyze in a dialysis bag with a molecular weight cut-off of 2000 Da for 1 day, concentrate by rotary evaporation, and freeze-dry to obtain glucosamine hyaluronate.

Embodiment 2

[0032] The difference from Example 1 is:

[0033] Weigh 3 g of hyaluronic acid with a molecular weight of 500,000 and 5 g of glucosamine hydrochloride, dissolve them in water, dialyze in a dialysis bag with a molecular weight cut-off of 500 Da for 3 days, concentrate by rotary evaporation, precipitate with ethanol, suction filter, and dry at 60 degrees Celsius After 8 hours, glucosamine hyaluronate was obtained.

Embodiment 3

[0035] The difference from Example 1 is:

[0036] Weigh 2g of hyaluronic acid with a molecular weight of 50,000 and 5g of glucosamine hydrochloride, dissolve them in water, use ion exchange, remove metal ions through a cation exchanger, and then enter an anion exchanger to remove anions to obtain glucosamine hyaluronic acid saline solution, spray-dried to obtain glucosamine hyaluronate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com