Bobbin paper dry strength agent and preparation method thereof

A technology of dry strength agent and bobbin paper, which is applied in the field of papermaking, can solve problems such as difficult to achieve elasticity, toughness and mechanical strength, and achieve the effects of reducing resource loss, good elasticity and toughness requirements, and improving ring compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

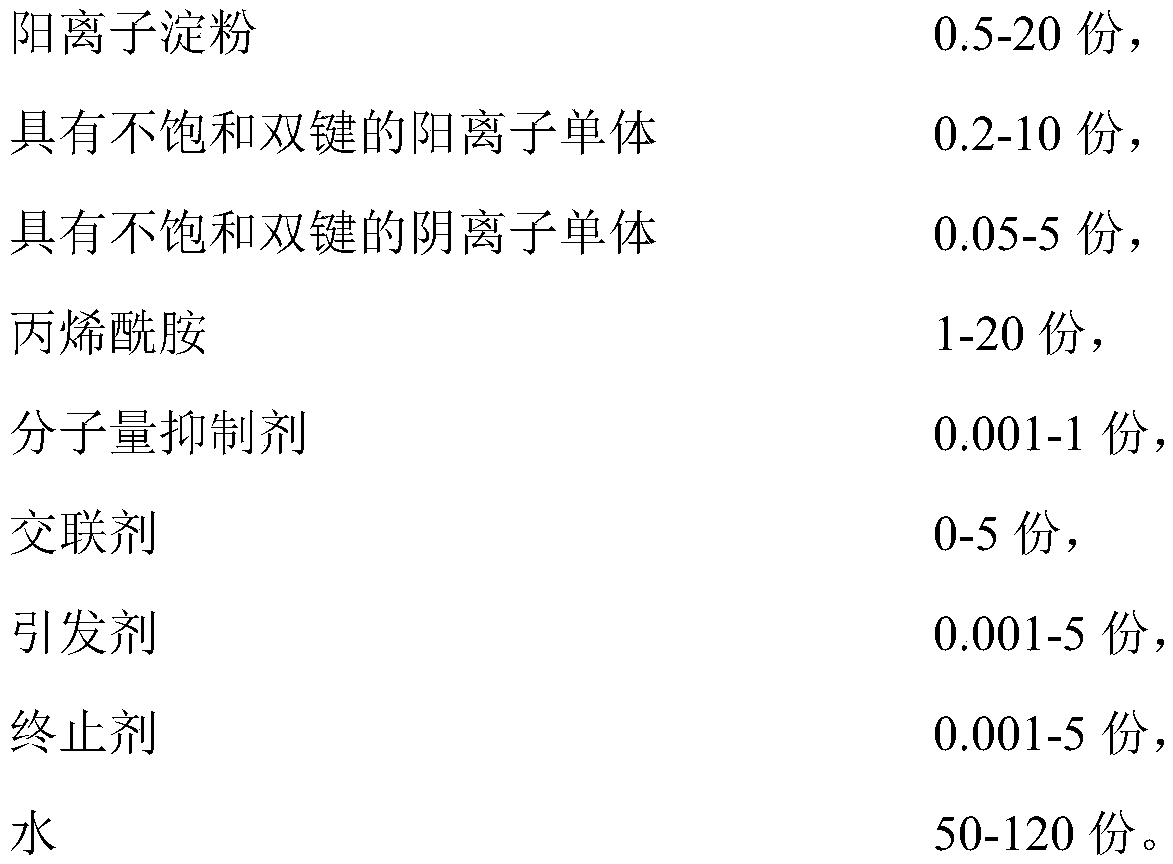

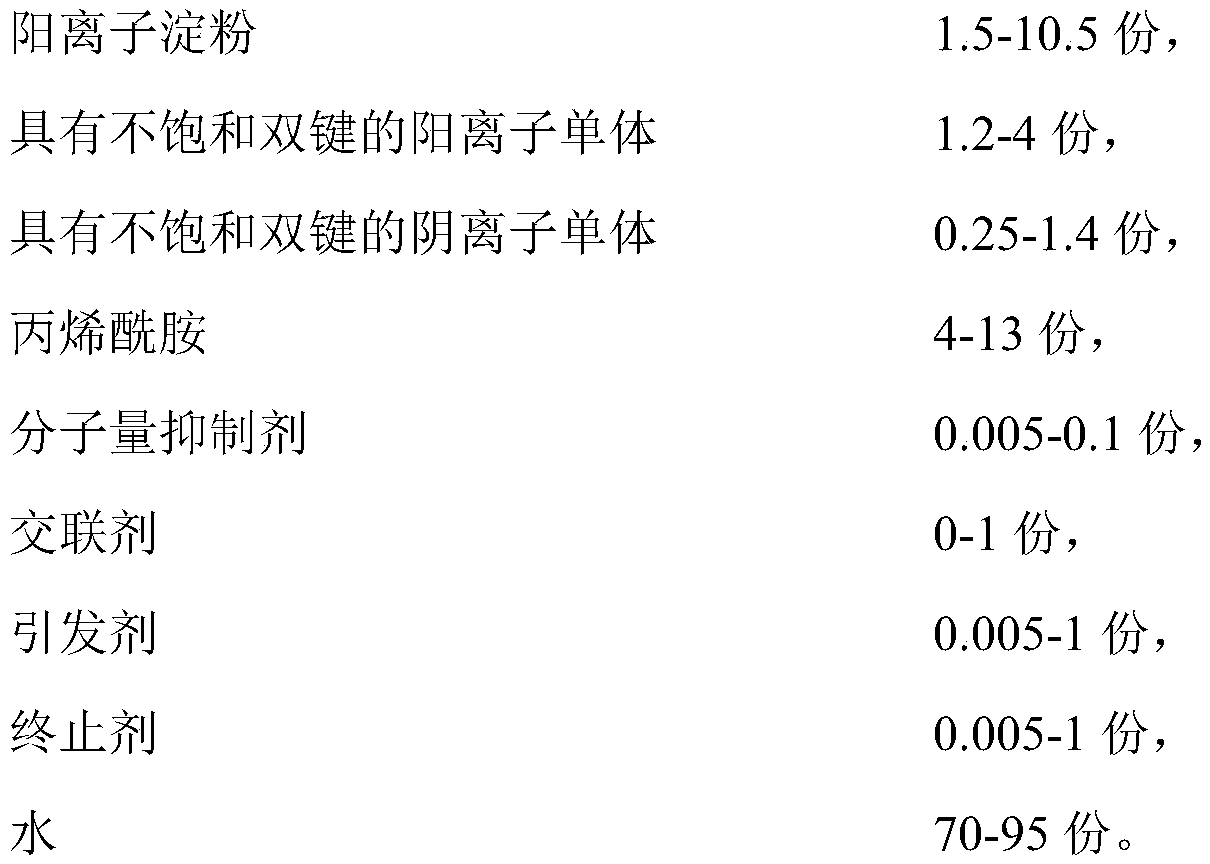

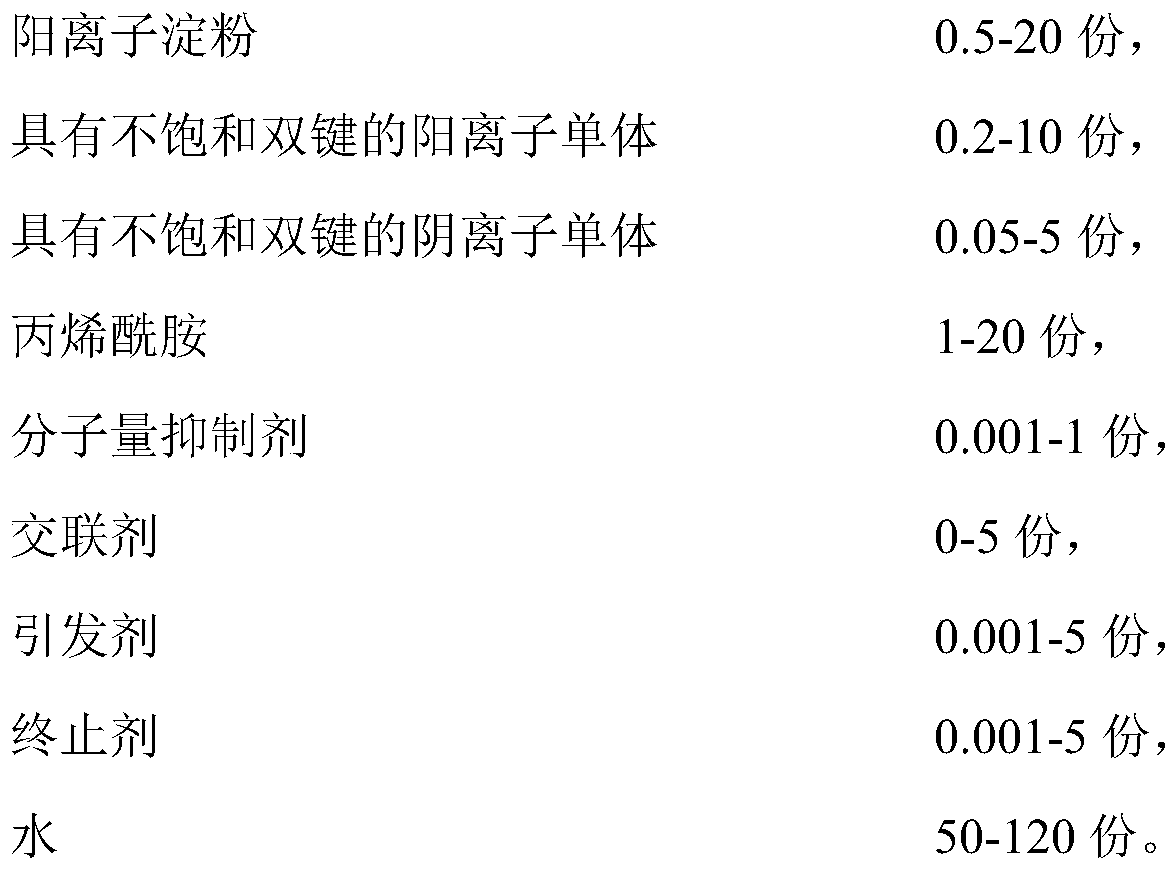

Method used

Image

Examples

Embodiment 1

[0030] A dry strength agent for bobbin paper, prepared through the following steps:

[0031] (1) 1.5 g of cationic starch with a degree of substitution of 0.07 was gelatinized at 50°C with 10 g of pure water and then kept at this temperature for 1 hour to obtain a cationic starch liquid for subsequent use;

[0032] (2) Put 0.38g of maleic acid, 4.0g of acryloyloxyethyltrimethylammonium chloride, 13g of acrylamide, and 71g of water into the reactor, start stirring to mix the materials evenly, then add molecular weight inhibitor 0.07 g and 0.007g of cross-linking agent, then feed nitrogen, and simultaneously raise the temperature of the material to 65°C, then add 0.01g of initiator to initiate polymerization;

[0033] (3) After the self-heating of the polymerization reaction stops (if the temperature exceeds 93°C during the self-heating process, it must be cooled with circulating water to keep the temperature not exceeding this temperature), add the cationic starch solution desc...

Embodiment 2

[0035] A dry strength agent for bobbin paper, prepared through the following steps:

[0036] (1) 3.0 g of cationic starch with a degree of substitution of 0.15 was gelatinized with 20 g of pure water at 50° C. and then kept at this temperature for 1 hour to obtain a cationic starch liquid for subsequent use;

[0037] (2) Put 0.45g of maleic acid, 3.2g of acryloyloxyethyltrimethylammonium chloride, 9.1g of acrylamide, and 64.2g of water into the reactor, start stirring to mix the materials evenly, then add molecular weight inhibitor 0.045g of cross-linking agent and 0.009g of cross-linking agent, then pass nitrogen gas, and simultaneously raise the temperature of the material to 65°C, then add 0.01g of initiator to initiate polymerization;

[0038] (3) After the self-heating of the polymerization reaction stops (if the temperature exceeds 93°C during the self-heating process, it must be cooled with circulating water to keep the temperature not exceeding this temperature), add t...

Embodiment 3

[0040] A dry strength agent for bobbin paper, prepared through the following steps:

[0041] (1) 4.5 g of cationic starch with a degree of substitution of 0.3 was gelatinized with 20 g of pure water at 50° C. and then kept at this temperature for 1 hour to obtain a cationic starch liquid for subsequent use;

[0042] (2) Put 0.51g of maleic acid, 3.1g of acryloyloxyethyltrimethylammonium chloride, 12.1g of acrylamide, and 59.7g of water into the reactor, start stirring to mix the materials evenly, then add molecular weight inhibitor 0.061g of cross-linking agent and 0.008g of cross-linking agent, then nitrogen gas was introduced, and at the same time, the temperature of the material was raised to 65°C, and then 0.012g of initiator was added to initiate polymerization;

[0043] (3) After the self-heating of the polymerization reaction stops (if the temperature exceeds 93°C during the self-heating process, it must be cooled with circulating water to keep the temperature not exceedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com