A kind of high thermal conductivity radiation cross-linked polyethylene pipe and its preparation method and application

A technology of radiation cross-linking and polyethylene pipes, which is applied in the field of high thermal conductivity radiation cross-linked polyethylene pipes and its preparation, can solve the problems of poor acid corrosion resistance, increased pipe brittleness, and low hydraulic pressure resistance of heat-conducting polyethylene pipes. Achieve the effects of cheap processing, improved brittleness, and wide service temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

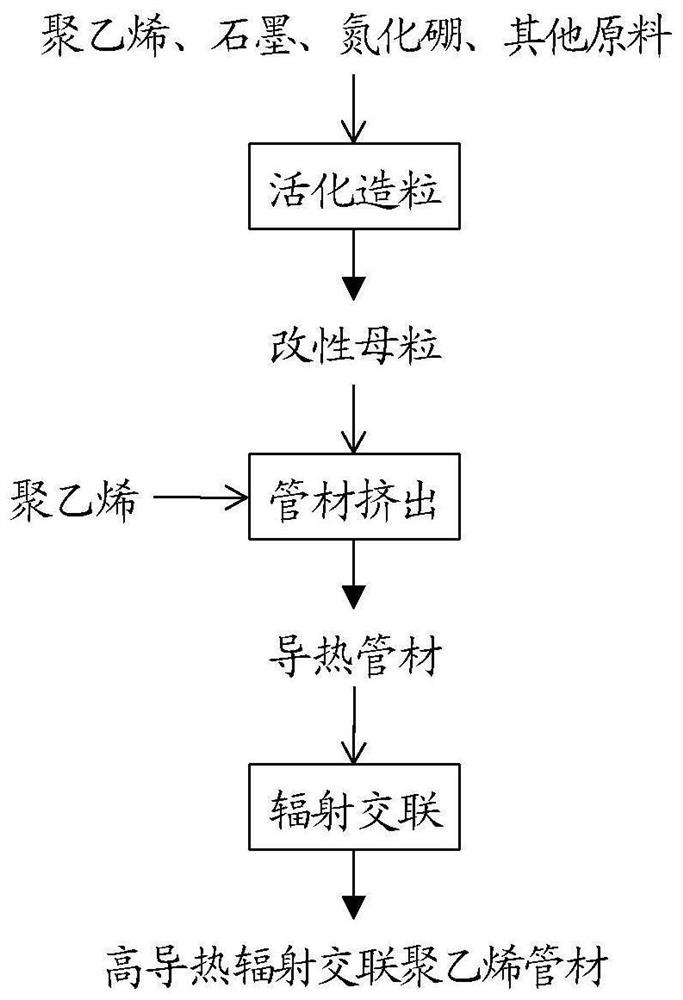

[0062] A high thermal conductivity radiation cross-linked polyethylene pipe, prepared by the following method (such as figure 1 shown):

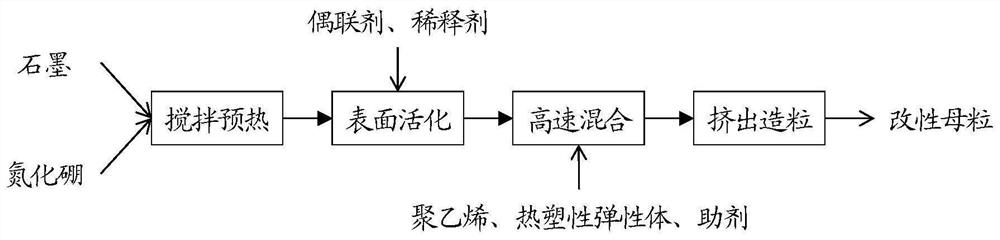

[0063] 1) Preparation of modified masterbatch (such as figure 2 shown):

[0064] Surface activation: first add 48 parts of 25 μm expandable graphite and 2 parts of 5 μm boron nitride into a high-speed mixer, and stir at 60~70 °C for 5 min; then take 1.5 parts of silane coupling agent KH-550 for 3 100% industrial white oil was diluted and added to the powder, and the stirring was continued for 8 min;

[0065] Mixing and granulation: 50 parts of high-density polyethylene 5502, 15 parts of thermoplastic elastomer (10 parts of ethylene-vinyl acetate copolymer and 5 parts of ethylene-propylene copolymer), 2 parts of cross-linking sensitizer diethylene glycol Alcohol diacrylate and 0.5 part of antioxidant (0.3 part of 1010 and 0.2 part of 168) were added to the surface-activated powder, and stirred at high speed for 12 min. Then, the mixed ra...

Embodiment 2

[0075] A high thermal conductivity radiation cross-linked polyethylene pipe is prepared by the following method:

[0076] 1) Preparation of modified masterbatch:

[0077] Surface activation: first add 16 parts of 45 μm natural graphite and 4 parts of 20 μm boron nitride into a high-speed mixer, and stir at 55~65 ° C for 3 min; After diluting with absolute ethanol, add it to the powder, and continue stirring for 7 min;

[0078] Mixing and granulation: 20 parts of medium density polyethylene DX800, 5 parts of thermoplastic elastomer (2 parts of ethylene-vinyl acetate copolymer and 3 parts of ethylene-octene copolymer), 2.5 parts of cross-linking sensitizer trimethylol Propane trimethacrylate and 0.5 part of antioxidant (0.3 part of 1010 and 0.2 part of 1178) were added to the surface-activated powder and stirred at high speed for 10 min. The same as in Example 1.

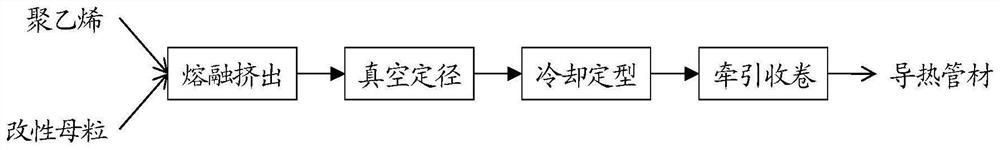

[0079] 2) Extrusion of heat-conducting pipes:

[0080] The modified masterbatch obtained in the previous step a...

Embodiment 3

[0084] A high thermal conductivity radiation cross-linked polyethylene pipe is prepared by the following method:

[0085] 1) Preparation of modified masterbatch:

[0086] Surface activation: first add 100 parts of 15 μm colloidal graphite and 25 parts of 2 μm boron nitride into a high-speed mixer, and stir at 70-80 °C for 5 min; then take 5 parts of aluminum-titanium composite coupling agent HY-133, Add 10 parts of industrial white oil to the powder after dilution, and continue to stir for 10 min;

[0087] Mixed granulation: 40 parts of medium density polyethylene SP980, 45 parts of thermoplastic elastomer (35 parts of ethylene-vinyl acetate copolymer and 10 parts of ethylene-butene copolymer), 3 parts of cross-linking sensitizer trimethylol Propane triacrylate and 1 part of antioxidant (0.7 part of 754 and 0.3 part of 168) were added to the surface-activated powder, and stirred at high speed for 15 min. The same as in Example 1.

[0088] 2) Extrusion of heat-conducting pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com