Photochromic water-based ink for textiles, and preparation method and application thereof

A photosensitive discoloration and textile technology, which is applied in the field of textile printing, can solve the problems of poor light fastness of printing paste, non-continuous processing of easy-plug net, slow coating drying speed, etc., and achieve bright color, excellent washability, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

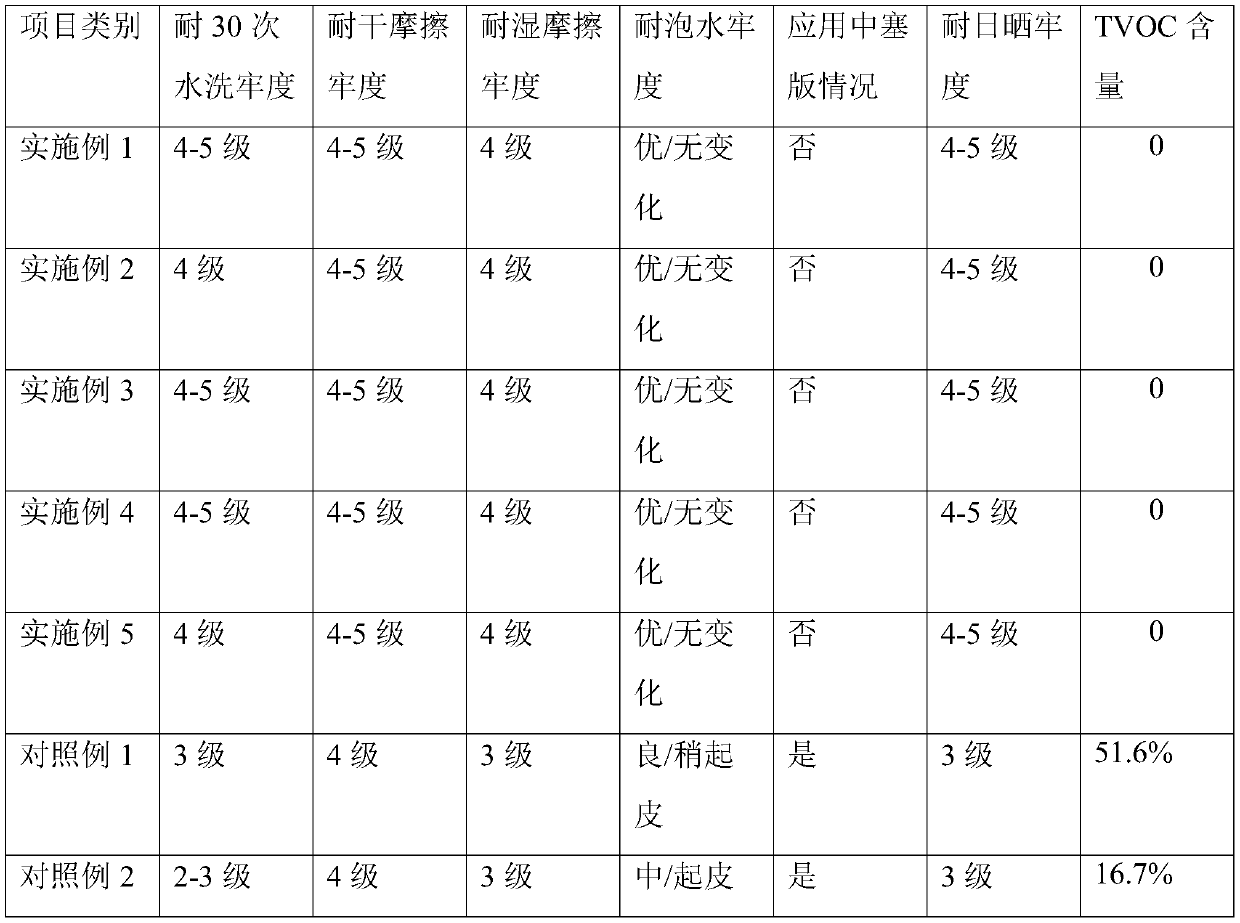

Examples

preparation example Construction

[0049] 1) Preparation of the water phase: 4 g of gum arabic emulsifier was added to 50 g of deionized water, and stirred to disperse the emulsifier evenly in the water.

[0050] 2) Preparation of oil phase: 4g of photochromic core material, 1g of ultraviolet absorbing core material, 1g of photostable core material, 4g of methyl methacrylate and 2g of pentaerythritol tetraacrylate were mixed evenly.

[0051] 3) Emulsification: After pouring the oil phase into the water phase, shear at a speed of 6000rpm for 20min at high speed; pour the emulsion into a three-necked flask, then add 0.15g of azobisisobutyronitrile, then raise the temperature to 80°C, Under the condition of reflux condensation, the reaction was carried out for 5 hours, and the stirring speed was 300 rpm / min. The product was centrifuged at 5000 rpm in a centrifuge, and the microcapsules were taken out after 10 minutes, washed with deionized water and ethanol respectively, and then freeze-dried to obtain a weather-r...

Embodiment 1

[0053] First dilute the thickener and deionized water according to the ratio of 1:1 for later use, adopt the following weight and feeding sequence, the preparation method of photochromic ink per 1000g parts by weight: take 150g of weather-resistant photochromic microcapsule powder (photochromic core material is spiral Pyran compound, UV absorbing core material is benzotriazole compound, light stable core material is hindered amine compound), add 344g deionized water and 20g dispersant and stir evenly, add 1g defoamer and stir evenly, add 1g Stir well with triethylamine, add 35g diluted spare thickener and stir well, add 120g acrylic resin and stir well, add 100g polyurethane resin and stir well, add 10g crosslinking agent and stir well, add 40g wax emulsion and stir well, add 2g anti Stir the oxidizing agent evenly, add 10g of penetrant and stir evenly, add 5g of leveling agent and stir evenly, add 45g of film-forming agent and stir evenly, add 2g of preservative and stir evenl...

Embodiment 2

[0056] First dilute the thickener and deionized water according to the ratio of 1:1 for later use, adopt the following weight and feeding sequence, the preparation method of photochromic ink per 1000g parts by weight: take 100g of weather-resistant photochromic microcapsule powder (photochromic core material is spiral Oxazine compounds, UV-absorbing core material is benzophenone compound, light-stable core material is hindered amine compound), add 263g deionized water and 30g dispersant and stir evenly, add 1.5g defoamer and stir evenly, add 0.8g of triethanolamine and stir well, add 35g of diluted spare thickener and stir well, add 150g of acrylic resin and stir well, add 100g of polyurethane resin and stir well, add 12g of cross-linking agent and stir well, add 50g of wax emulsion and stir well, add 3g Stir the antioxidant well, add 20g penetrating agent and stir well, add 7g leveling agent and stir well, add 40g film forming agent and stir well, add 3g preservative and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com