Polylactic acid fiber spinning process

A technology of polylactic acid fiber and spinning process, which is applied in the field of spinning process, can solve the problems of high brittleness of polylactic acid, restricting the breadth and depth of polylactic acid, and high glass transition temperature, so as to reduce residual stress and improve elongation at break , The effect of increasing the thermal degradation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

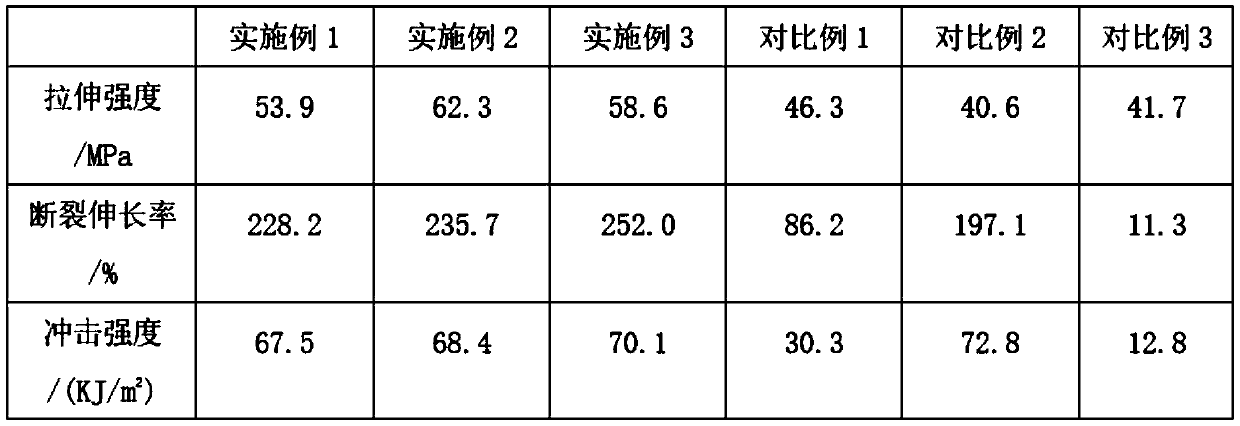

Examples

Embodiment 1

[0031] A polylactic acid fiber spinning process, the process may further comprise the steps:

[0032] Step 1: adding polylactic acid to a mixed solvent, stirring and dissolving at room temperature, then adding tannic acid, stirring at room temperature for 5-7 hours, standing for 0.5 hours to remove foam, and obtaining a pretreatment solution;

[0033] Wherein, the mixed solvent is obtained by mixing dichloromethane and N,N-dimethylformamide according to a volume ratio of 7:3;

[0034] The solid-to-liquid ratio of polylactic acid to the mixed solvent is 1:10, and the mass of tannic acid is 40% of the mass of polylactic acid.

[0035] Step 2, adding a plasticizer to the pretreatment solution first, then adding an initiator, stirring and dissolving to obtain a spinning solution;

[0036] Wherein, the addition of plasticizer is 10% of polylactic acid quality; 0.5% of;

[0037] Step 3, spinning the spinning solution using an electrospinning device to obtain polylactic acid fiber...

Embodiment 2

[0045] A polylactic acid fiber spinning process, the process may further comprise the steps:

[0046]Step 1, adding polylactic acid to the mixed solvent, stirring and dissolving at room temperature, then adding tannic acid, stirring at room temperature for 6 hours, standing for 0.5 hours to remove foam, and obtaining a pretreatment solution;

[0047] Wherein, the mixed solvent is obtained by uniformly mixing dichloromethane and N,N-dimethylformamide according to a volume ratio of 7:3;

[0048] The solid-to-liquid ratio of polylactic acid to the mixed solvent is 1:10, and the mass of tannic acid is 40% of the mass of polylactic acid.

[0049] Step 2, adding a plasticizer to the pretreatment solution first, then adding an initiator, stirring and dissolving to obtain a spinning solution;

[0050] Wherein, the addition of plasticizer is 15% of polylactic acid quality; 1%;

[0051] Step 3, spinning the spinning solution using an electrospinning device to obtain polylactic acid f...

Embodiment 3

[0059] A polylactic acid fiber spinning process, the process may further comprise the steps:

[0060] Step 1, adding polylactic acid to the mixed solvent, stirring and dissolving at room temperature, then adding tannic acid, stirring at room temperature for 7 hours, standing for 0.5 hours to remove foam, and obtaining a pretreatment solution;

[0061] Wherein, the mixed solvent is obtained by uniformly mixing dichloromethane and N,N-dimethylformamide according to a volume ratio of 7:3;

[0062] The solid-to-liquid ratio of polylactic acid to the mixed solvent is 1:10, and the mass of tannic acid is 40% of the mass of polylactic acid.

[0063] Step 2, adding a plasticizer to the pretreatment solution first, then adding an initiator, stirring and dissolving to obtain a spinning solution;

[0064] Wherein, the add-on of plasticizer is 20% of the quality of polylactic acid; 2% of

[0065] Step 3, spinning the spinning solution using an electrospinning device to obtain polylacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com