High-performance nano hybrid reverse osmosis membrane and preparation method thereof

A reverse osmosis membrane, a high-performance technology, applied in chemical instruments and methods, reverse osmosis, semi-permeable membrane separation, etc., can solve the problems of nanomaterial agglomeration and easy shedding, and achieve reduced hydrolysis, reduced shedding, and excellent anti-pollution performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

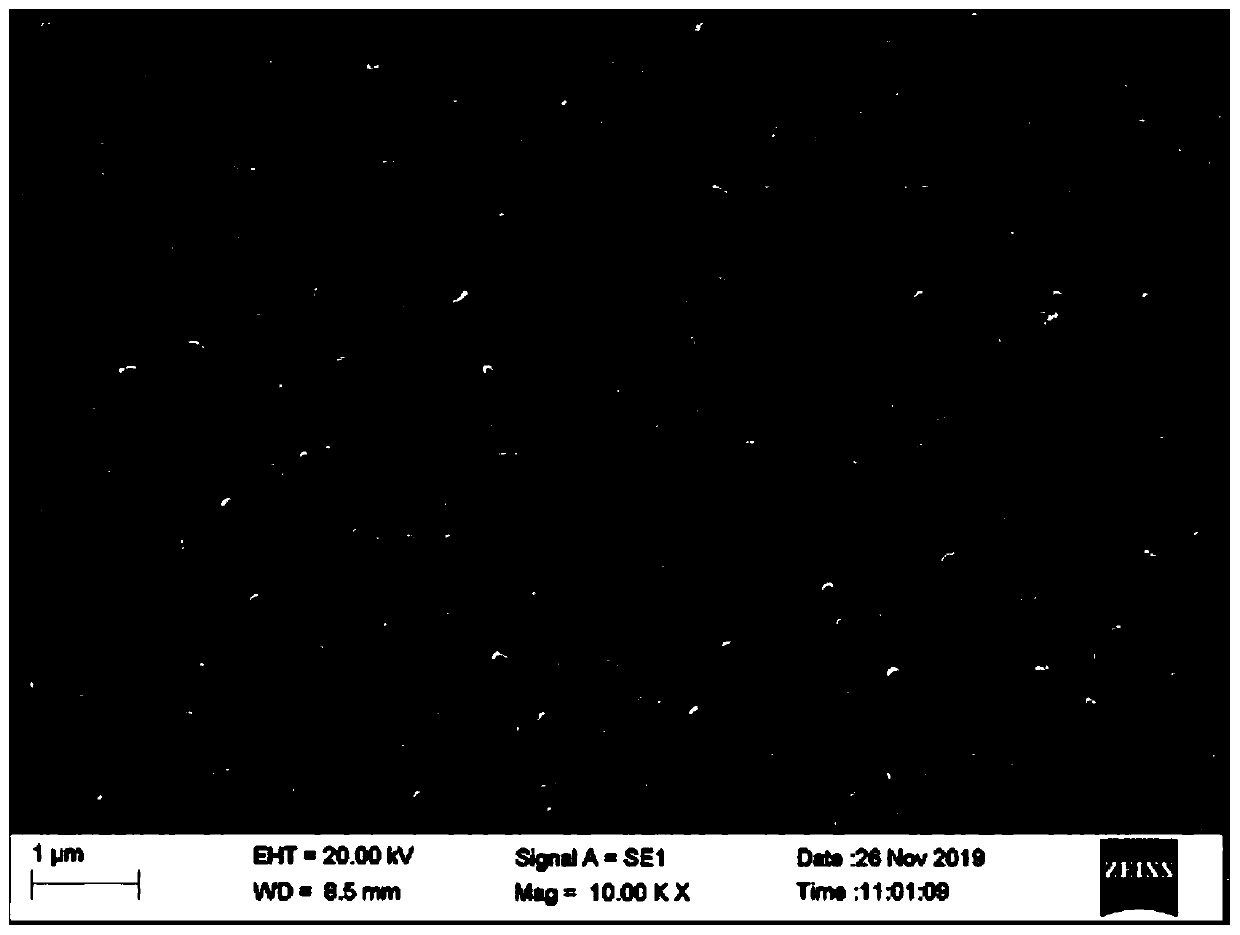

Image

Examples

Embodiment 1

[0028] A preparation of a high-performance nano-hybrid reverse osmosis membrane, the specific implementation steps are as follows:

[0029] (1) 40g camphorsulfonic acid and 25g triethylamine are mixed uniformly earlier, as catalyst, then add 20g m-phenylenediamine, 15g dimethylformamide (aqueous phase modifier) and 15g chitosan (crosslinking agent) successively agent), then diluted to 1000g, and mixed uniformly to obtain m-phenylenediamine aqueous phase solution;

[0030] (2) Dissolve 2g of trimesic acid chloride in n-hexane (organic solvent), then add 0.1g of tetraethyl orthosilicate (nano-precursor) and mix evenly, and add a small amount of glacial acetic acid to adjust the pH value of the solution to 5 to obtain Modified trimesoyl chloride oil phase solution;

[0031] (3) First, the porous polysulfone support layer is placed in the m-phenylenediamine aqueous phase solution obtained in step (1) and soaked for 0.5 min, and then soaked in the modified trimesoyl chloride oil...

Embodiment 2~9

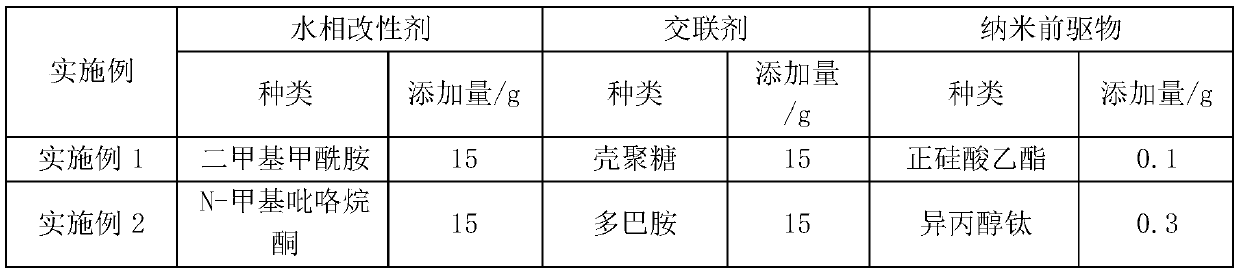

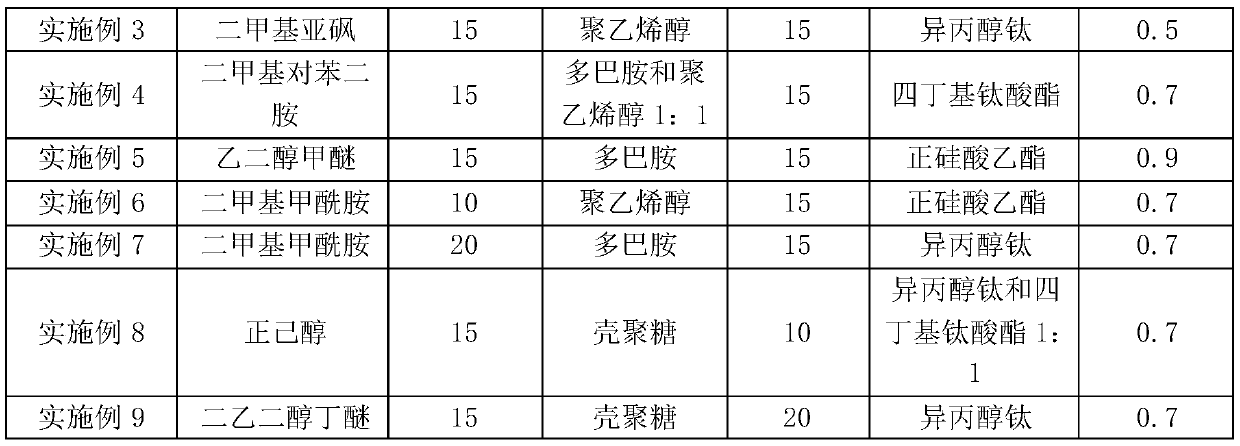

[0034] The preparation method of the high-performance nano-hybrid reverse osmosis membrane in Examples 2~9 is basically the same as Example 1, and the difference is only: the aqueous phase modifying agent added in the step (1), cross-linking agent and step ( 2) The type and amount of the nano-precursor added are different, as shown in Table 1:

[0035] Table 1

[0036]

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com