Method for synthesizing monatomic catalyst, monatomic catalyst and application

A catalyst and atomic technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complex synthesis methods, insufficient performance of SACs, catalyst loss of activity, etc., and achieve simple and effective synthesis methods , Good product selectivity, cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

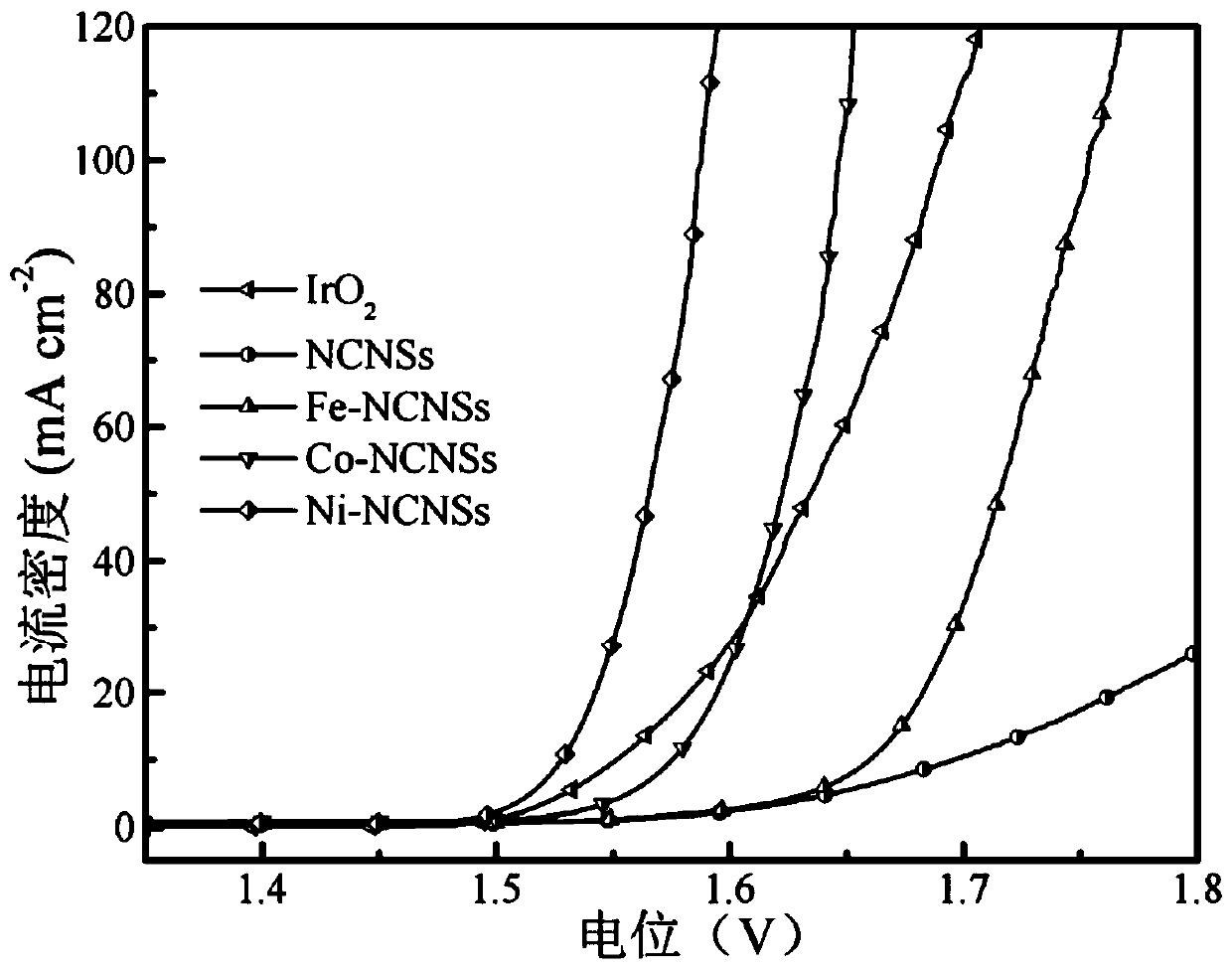

[0035]Under magnetic stirring, add 8mL of emulsions containing 16wt% polystyrene nanospheres to the 50mL centrifuge tube (the emulsion density is calculated by 1.0g / mL, so 8mL emulsions contain 1.3 grams of PS nanospheres), 50wt% cyanamide Aqueous solution 2mL (50wt% cyanamide aqueous solution is 1.09g / mL, 2mL aqueous solution contains 1.2 grams of cyanamide), furfural 1mL, 0.1M dilute hydrochloric acid 0.4mL (pH of reaction solution is at 2.5~3), 10g / mL L (based on Fe element content) of FeCl 3 Solution 0.75mL, sealed reaction at 60°C, 500rpm stirring for 72h, placed in a drying oven at 100°C for 24h to obtain a high polymer; put the obtained high polymer in a tube furnace, in a nitrogen atmosphere to The temperature was raised to 1000°C at a rate of 4°C / min and maintained for 2 hours, and then cooled to room temperature at a rate of 6°C / min, and the obtained solid was fully ground to a fine powder to obtain nitrogen-doped carbon nanosheets anchored by a single Fe atom , cal...

Embodiment 2

[0037] Add 8mL of emulsion containing 16wt% polystyrene nanospheres, 2mL of 50wt% cyanamide aqueous solution, furfural 1mL, 0.1M dilute hydrochloric acid 0.4mL, 10g / L (in terms of Co element content) to 50mL centrifuge tube under magnetic stirring successively. ) CoCl 2 Solution 0.75mL, sealed reaction at 60°C, 500rpm stirring for 72h, placed in a drying oven at 100°C for 24h to obtain a high polymer; put the obtained high polymer in a tube furnace, in a nitrogen atmosphere to The temperature was raised to 900°C at a rate of 4°C / min and maintained for 3h, then cooled to room temperature at a rate of 6°C / min, and the obtained solid was fully ground to a fine powder to obtain nitrogen-doped carbon nanosheets anchored by a single Co atom , called Co-NCNSs.

Embodiment 3

[0039] Add 8mL of emulsion containing 16wt% polystyrene nanospheres, 2mL of 50wt% cyanamide aqueous solution, furfural 1mL, 0.1M dilute hydrochloric acid 0.4mL, 10g / L (in terms of Ni element content) to 50mL centrifuge tube successively under magnetic stirring. ) NiCl 2 Solution 0.75mL, sealed reaction at 60°C, 500rpm stirring for 72h, placed in a drying oven at 100°C for 24h to obtain a high polymer; put the obtained high polymer in a tube furnace, in a nitrogen atmosphere to The temperature was raised to 900°C at a rate of 4°C / min and maintained for 3 hours, then cooled to room temperature at a rate of 6°C / min, and the obtained solid was fully ground to a fine powder to obtain nitrogen-doped carbon nanosheets anchored by a single Ni atom , called Ni-NCNSs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com