Method for controllably preparing strong-luminescence rare earth up-conversion material

A rare earth up-conversion, luminescent material technology, applied in luminescent materials, chemical instruments and methods, nano-optics, etc., can solve the problems of low luminous efficiency and incompletely clear mechanism, and achieve high luminous intensity, uniform size, and easy mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 0.2428g (0.80mmol) YCl 3 ·6H 2 O, 0.0698g (0.18mmol) YbCl 3 ·6H 2 O, 0.0076g (0.02mmol) ErCl 3 ·6H 2 O, 6mL oleic acid and 15mL octadecene were added to a 100mL three-necked flask, and stirred at 160°C for 1 hour under the protection of anhydrous, oxygen-free and inert gas to form a homogeneous transparent solution with a slight yellowish tinge. Then the system was lowered to room temperature, and dissolved with 0.1g (2.5mmol) NaOH and 0.1482g (4mmol) NH 4 10mL of methanol solution of F, stir at room temperature for 60min, heat up to 55-60°C, continue to stir for 60min to remove methanol, then heat up to 110-120°C and vacuum for 20min, and finally heat up to 300°C at a speed of 38°C / min and hold for 60min. After cooling down to room temperature, centrifuge and wash with absolute ethanol to obtain a rare earth up-conversion luminescent material NaYF with a size of 10nm 4 : 18% Yb, 2% Er (see figure 1 ).

[0035] 0.2428g (0.80mmol) YCl 3 ·6H 2 O, 0.0698g (0.18mm...

Embodiment 2

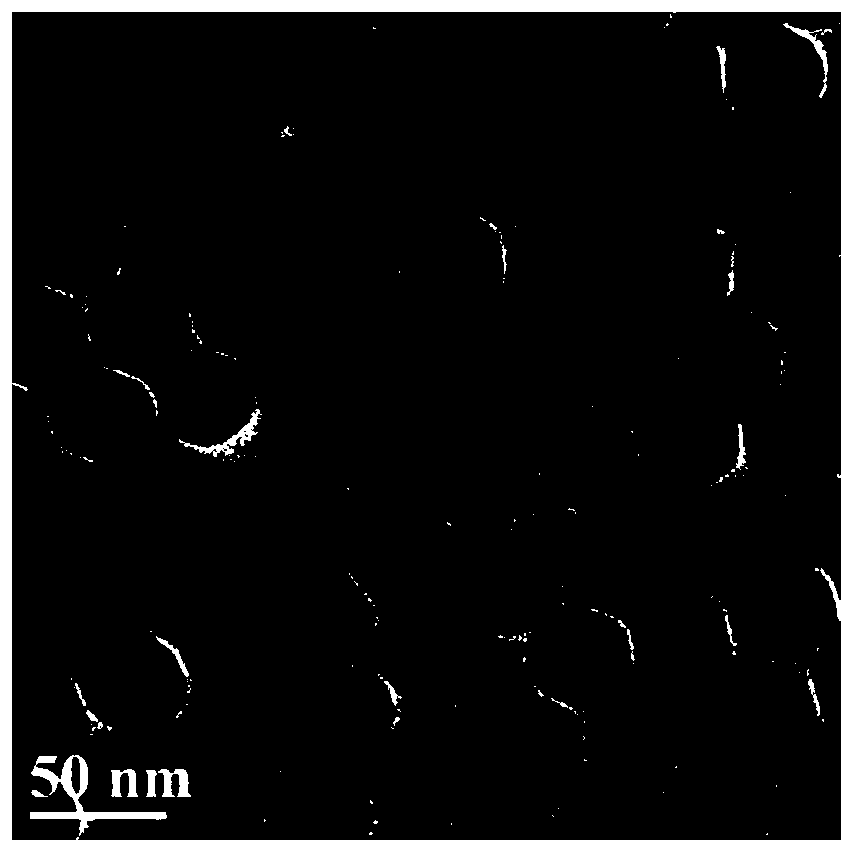

[0043] In this example, 20 mg of NaYF with a size of 10 nm 4 : 18% Yb, 2% Er with 40mg of NaYF with a size of 35nm 4 : 18%Yb, 2%Er are uniformly dispersed in 3mL cyclohexane, other steps are the same as in Example 1, and the rare earth up-conversion material NaYF having a size of 36nm is obtained 4 : 18% Yb, 2% Er (see Figure 8 ).

Embodiment 3

[0045] In this example, 20 mg of NaYF with a size of 10 nm 4 : 18% Yb, 2% Er with 80mg of NaYF with a size of 35nm 4 : 18%Yb, 2%Er are uniformly dispersed in 3mL cyclohexane, other steps are the same as in Example 1, and the rare earth up-conversion material NaYF having a size of 36nm is obtained 4 : 18% Yb, 2% Er (see Figure 9 ).

[0046] In the above examples, two different sizes of rare earth up-conversion luminescent materials NaYF 4 : 18%Yb, 2%Er can also use different sizes of NaGdF 4 : 18% Yb, 2% Er, NaLuF 4 : 18%Yb, 2%Er, NaYbF 4 : 18% Yb, 2% Er, NaLuF 4 : 18%Yb, 2%Tm, etc. are replaced, and then the raw materials of these two different sizes are reacted by the method of the present invention, and the rare earth up-conversion luminescent material with obviously enhanced luminescence can also be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com