Essence lotion and production process thereof

A production process and technology of essence milk, applied in the field of skin care products, can solve the problems of high storage difficulty, inability to prevent microbial damage, and aggravation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

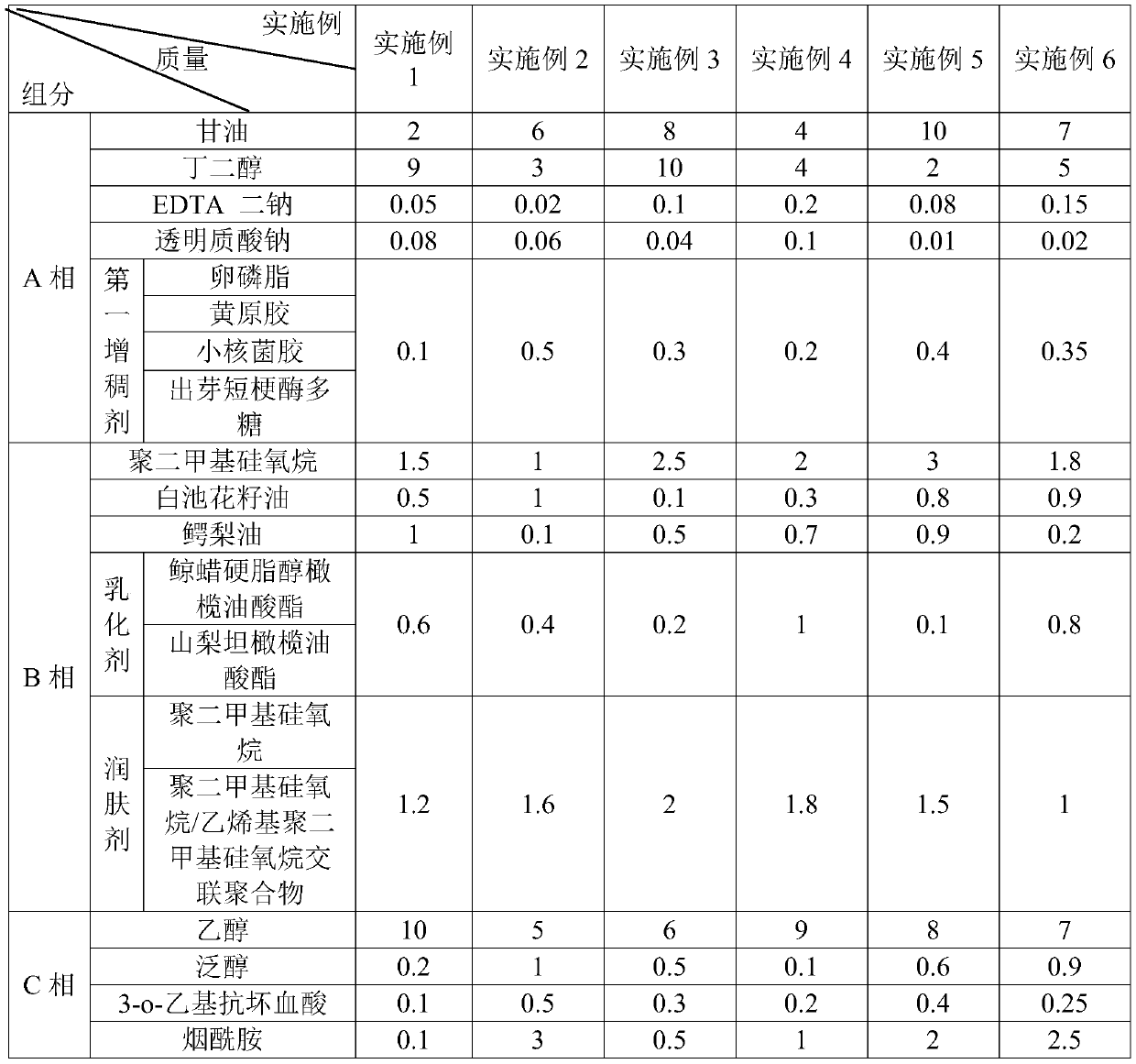

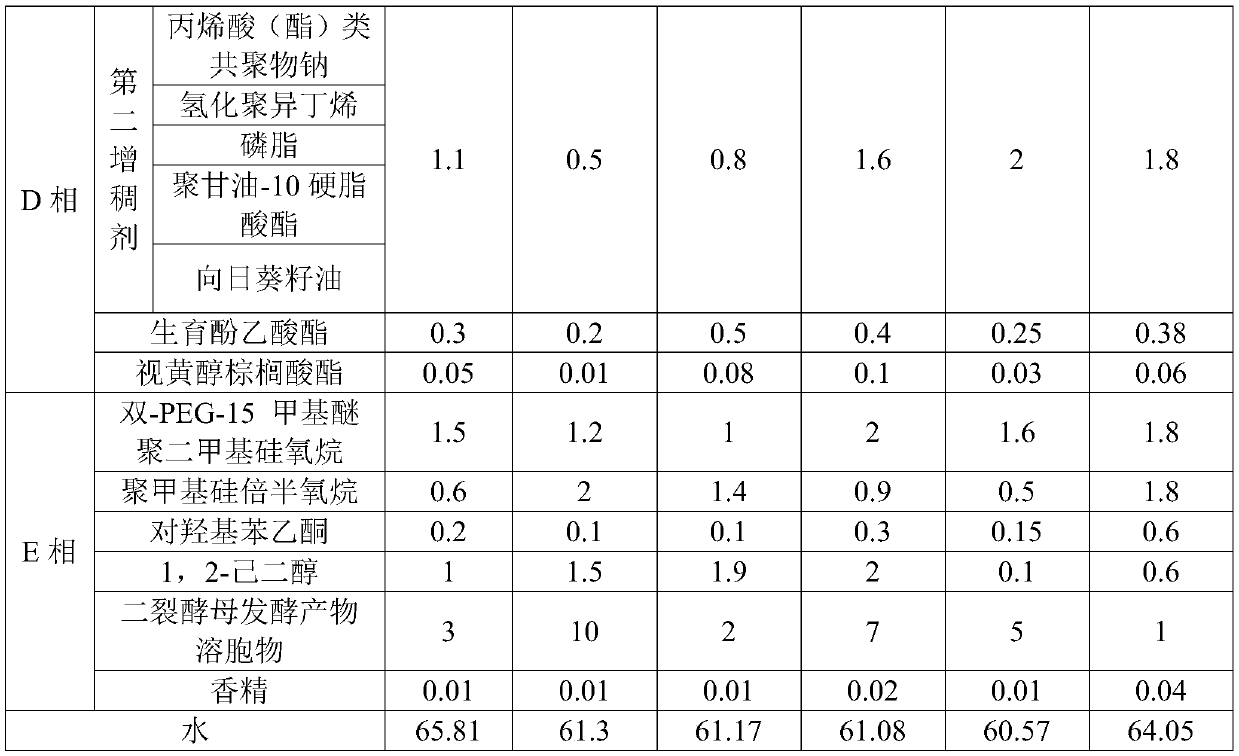

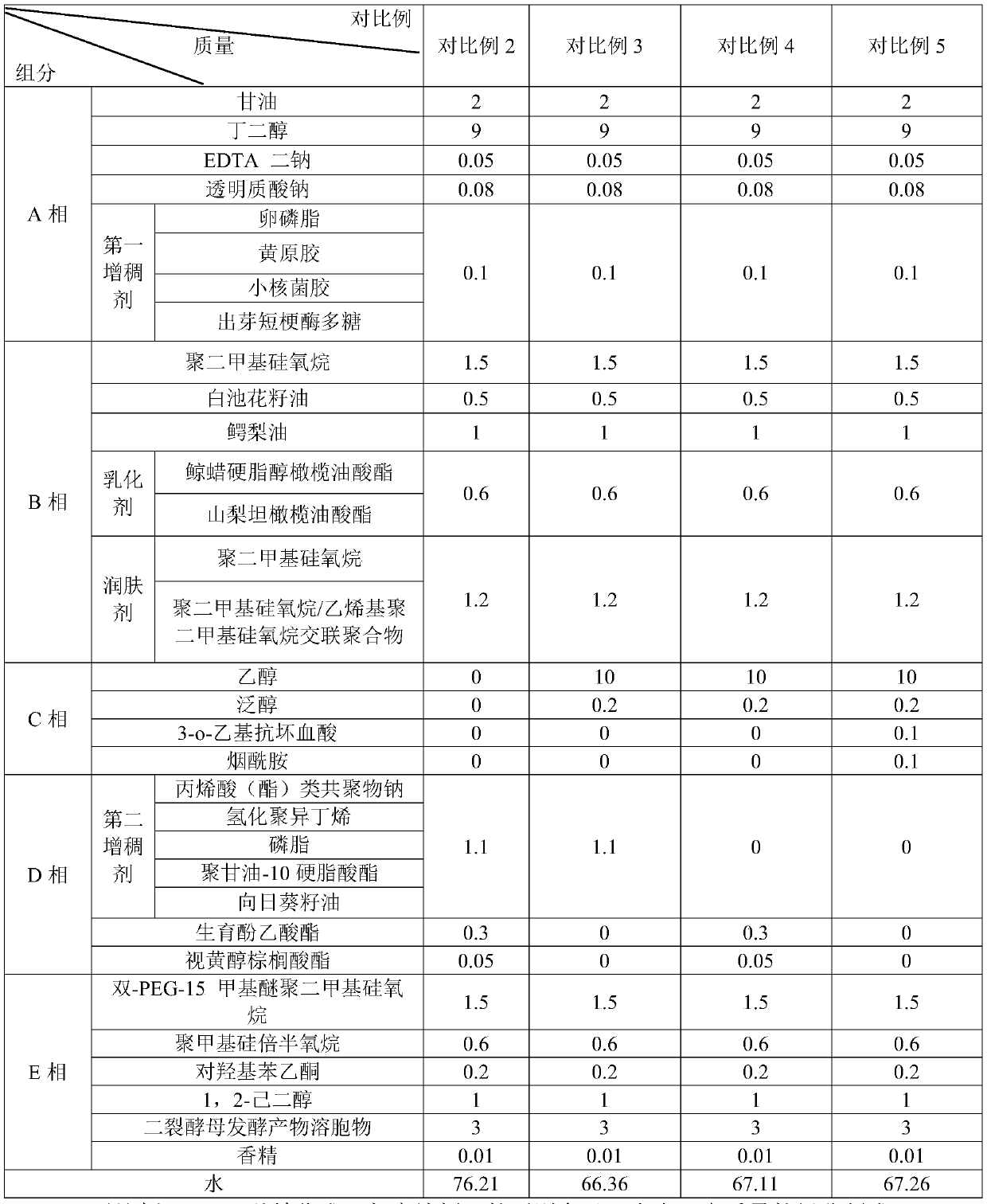

Examples

Embodiment 1

[0090] Embodiment 1: a kind of essence milk, is made by the component of quality in table 1, and preparation steps are as follows:

[0091] Step 1, fully mix half of the deionized water and the components in phase A, and raise the temperature at the same time to obtain the phase A mixture;

[0092] In step 2, the components in phase B are fully mixed, and the temperature is raised at the same time to obtain a phase B mixture;

[0093] Step 3, fully mix the remaining deionized water and the components in phase C, and raise the temperature to 55°C at the same time to obtain the phase C mixture;

[0094] Step 4, fully mixing the components in the D phase to obtain the D phase mixture;

[0095] Step 5, fully mixing the phase B mixture with the phase A mixture to obtain the first mixture;

[0096] Step 6: Magnetically stir the mixture of phase C, add the mixture of phase D at a temperature of 60°C to the mixture of phase C at a temperature of 60°C for heat preservation and mixing...

Embodiment 7

[0103] Embodiment 7: A kind of essence milk, the difference with embodiment 1 is that the first thickener is composed of lecithin, xanthan gum, sclerotin, pullulanase with a mass ratio of 1:6:8:3 Composed of polysaccharides; the second thickener consists of sodium acrylic acid (ester) copolymer, hydrogenated polyisobutene, phospholipids, polyglycerol-10 stearate, and sunflower seed oil in a mass ratio of 3:5:5:1:2 .

Embodiment 8

[0104] Embodiment 8: A kind of essence milk, the difference with embodiment 1 is that the first thickener is composed of lecithin, xanthan gum, sclerotin, pullulanase with a mass ratio of 2:9:5:3 Composed of polysaccharides; the second thickener consists of sodium acrylic acid (ester) copolymer, hydrogenated polyisobutene, phospholipid, polyglycerol-10 stearate, sunflower seed oil with a mass ratio of 2:6:1:3:2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com